Sys-EV-560-Man August2016 REV A • 7

6 • Sys-EV-560-Man August2016 REV A

EN

EN

TROUBLESHOOTING

Problem

Cause

Correction

Softener fails to regenerate.

Electrical service to unit has been

interrupted.

Assure permanent electrical service (check fuse,

plug, pull chain, or switch).

Timer is defective.

Replace timer.

Power failure.

Reset time of day.

Meter not counting liters.

Check to see if cable is inserted into meter

assembly.

Softener delivers hard water.

By-pass valve is open.

Close by-pass valve.

No salt is in brine tank.

Add salt to brine tank and maintain salt level

above water level.

Injector screen plugged.

Clean injector screen.

Insufficient water flowing into brine tank.

Check brine tank fill time and clean brine line flow

control if plugged.

Hot water tank hardness.

Repeated flushings of the hot water tank is

required.

Leak at distributor tube.

Make sure distributor tube is not cracked. Check

O-ring and tube pilot.

Internal valve leak.

Replace seals and spacers and/or piston.

Unit used too much salt.

Improper salt setting.

Check salt usage and salt setting.

Excessive water in brine tank.

See “Excessive water in brine tank”.

Loss of water pressure.

Insufficient backwash flow rate

or Backwash cycle to short to

clean the resin bed

Iron buildup in line to water conditioner.

Clean line to water conditioner.

Iron buildup in water conditioner.

Clean control and add mineral cleaner to mineral

bed. Increase frequency of regeneration.

Inlet of control plugged due to foreign

material broken loose from pipes by recent

work done on plumbing system.

Remove piston and clean control.

Insufficient backwash flow rate or

Backwash cycle to short to clean the resin

bed.

Increase backwash cycle duration.

Check the DLFC size match with the tank size

and that it is not partially plug.

Check that drain line is not partially plugged

Loss of resin through drain

line.

Air in water system.

Assure that well system has proper air eliminator

control. Check for dry well condition.

Upper and/or lower screen damaged.

Check and replace damaged parts.

Iron in conditioned water.

Fouled resin bed.

Check backwash, brine draw, and brine tank

Increase frequency of regeneration. Increase

backwash time.

Excessive water in brine tank.

Plugged drain line flow control.

Clean flow control.

Incorrect brine setting.

Check valve settings.

SYSTEM START-UP continued

Manually Initiating a Regeneration

1. When timer is in service, press

button for 5 seconds on

the main screen.

2. The timer advances to Regeneration Cycle Step #1

(backwash), and begins programmed time count down.

3. Press the

button once to advance valve to Regeneration

Cycle Step #2 (brine draw & slow rinse ).

4. Press the

button once to advance valve to Regeneration

Cycle Step #3 (rapid rinse)

5. Press the

button once to advance valve to Regeneration

Cycle Step #4 (brine refill full cycle).

NOTE: A queued regeneration can be initiated by pressing

the

button. To clear a queued regeneration,

press the

button again to cancel. If regeneration

occurs for any reason prior to the delayed

regeneration time, the manual regeneration request

shall be cleared.

Cycle Step #

EVOLIO560

8

EVOLIO560

15

EVOLIO560

20

EVOLIO560

30

1. Backwash

2 min

3 min

3 min

4 min

2. Brine draw

& Slow rinse

20 min

38 min

76 min

114 min

3. Rapid Rinse

4 min

7 min

5 min

8 min

4. Brine

Tank Refill

3 min

5 min

7 min

11 min

DISINFECTION OF WATER SOFTENERS

NOTE: Every water softener should be disinfected after

installation; some will require periodic disinfection

during their normal life. In a few cases, disinfection with

every regeneration is recommended.

NOTE: Depending upon the conditions of use, the style of

softener, the type of ion exchanger, and the disinfectant

available, a choice can be made among the following

methods:

Sodium or Calcium Hypochlorite

5.25% Sodium Hypochlorite

IMPORTANT: Do not use any other chemical substance with

out manufacturer approval.

1.

Dosage: 0.022 fluid liters

2. Proceed with the normal regeneration.

ADDING SALT

NOTE: Your softener comes pre-charged and will supply you

with a day or two of soft water. Salt must be added to

the salt tank for the system to regenerate properly. This

must be done within the first 24 - 28 hours. For the

start up use the 10Kg salt bag included

Types of Salt

Any pellet type salt is recommended due to its cleanliness

and availability. Other salts such as block, solar and rock salt

can be used; however, they may alter performance or cause

maintenance problems.

Amount of Salt

One tank units have a salt capacity of (see table pag 2).

You are not required to fill your salt tank to capacity. It is

recommended that the salt level in the salt tank always be

above the water level in the tank. This will assure that the unit

always has the correct salt dosage when it regenerates.

MAINTENANCE AND REPAIR

This unit is designed and constructed to treat the most difficult

of water. Various screens have been included in the system to

protect orifices.

BEFORE doing any service work, be sure all screens are clean

and will pass water. Periodic cleaning of the screens will insure

long-term unit performance.

Lack of treated (soft) water is constant.

1. No salt in tank — Add salt to tank

2. Dirty screens — Clean screens

3. Faulted timer motor — Replace

Lack of treated (soft) water is intermittent.

Intermittent is often indicated by untreated water from the

heater (hot water) while the cold water tastes good. Intermittent

indicates excess water usage, a change in water chemistry,

or an improper frequency of regeneration. Review entire

application.

1. Low salt setting — Adjust brine value

2. Water consumption increased — Check for household leaks

3. Too infrequent regenerations — Review sizing and

reprogram timer

Brine tank overflow

1. Plugged screens or injector — Clean

2. Defective Brine Valve — Clean or replace

3. Defective timer or timer motor — Replace

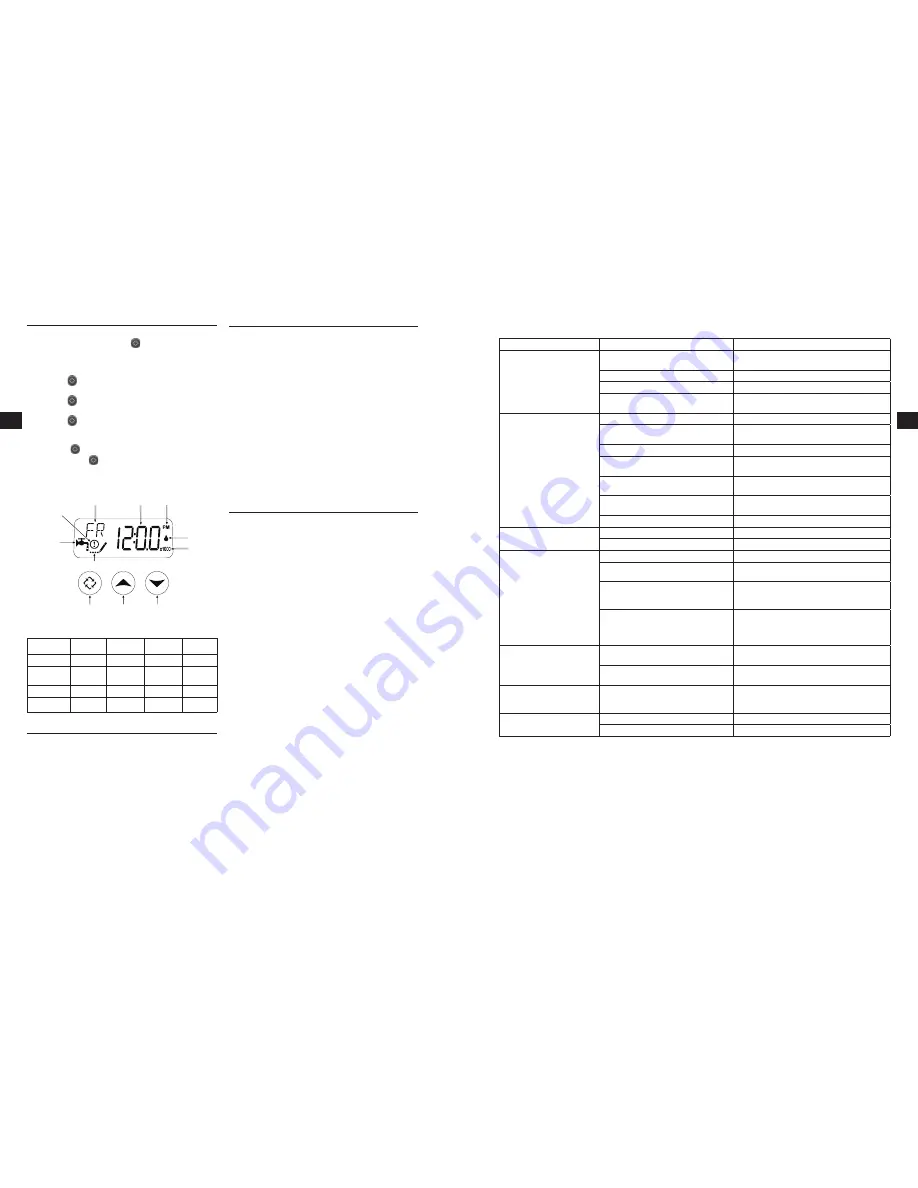

Service

Icon

Parameter Display

Programming Icon

Extra Cycle

Button

Down Button

Up Button

Data Display

PM Indicator

Flow Indicator

x1000 Indicator

Figure 9

Error/

Information

Icon