P/N 471438

Rev. A 2-4-2000

COMMISSIONING

FILLING THE SYSTEM

1.

Ensure all power is off and all external controls are off.

2.

Open all supply and return valves.

3.

Fill heating system to minimum operating pressure.

4.

Purge air from all system pipe work recharging the system to the minimum operating pressure.

INITIAL FIRING

Before commissioning the appliance, the whole gas installation, including the meter, MUST be pre-purged and

tested for gas soundness in accordance with BS 6891:1988.

Important: Open all doors and windows, extinguish naked flames and DO NOT SMOKE whilst purging the gas

line.

Before commencing the commissioning procedure, ensure that the gas service cock is turned on, electricity supply

is isolated.

1.

Be sure that the system has been adequately vented of air and is water - tight.

2.

Connect an accurate manometer to the Gas Valve outlet connection.

3.

Open gas shut-off valve.

4.

Following appropriate lighting instructions in the users section of this manual, checking that the burner

setting pressure is as detailed on the appliance database and specification sheets of this manual.

If burner pressure requires adjustment, the adjuster location is shown for the specific appliance category,

below.

IMPORTANT NOTE

Adjustment of the setting pressure for category

I

2E+

must only be done with the main burners off

following removal of the sealing cap. Always replace the sealing cap before refiring, checking for gas

soundness with leak detection fluid.

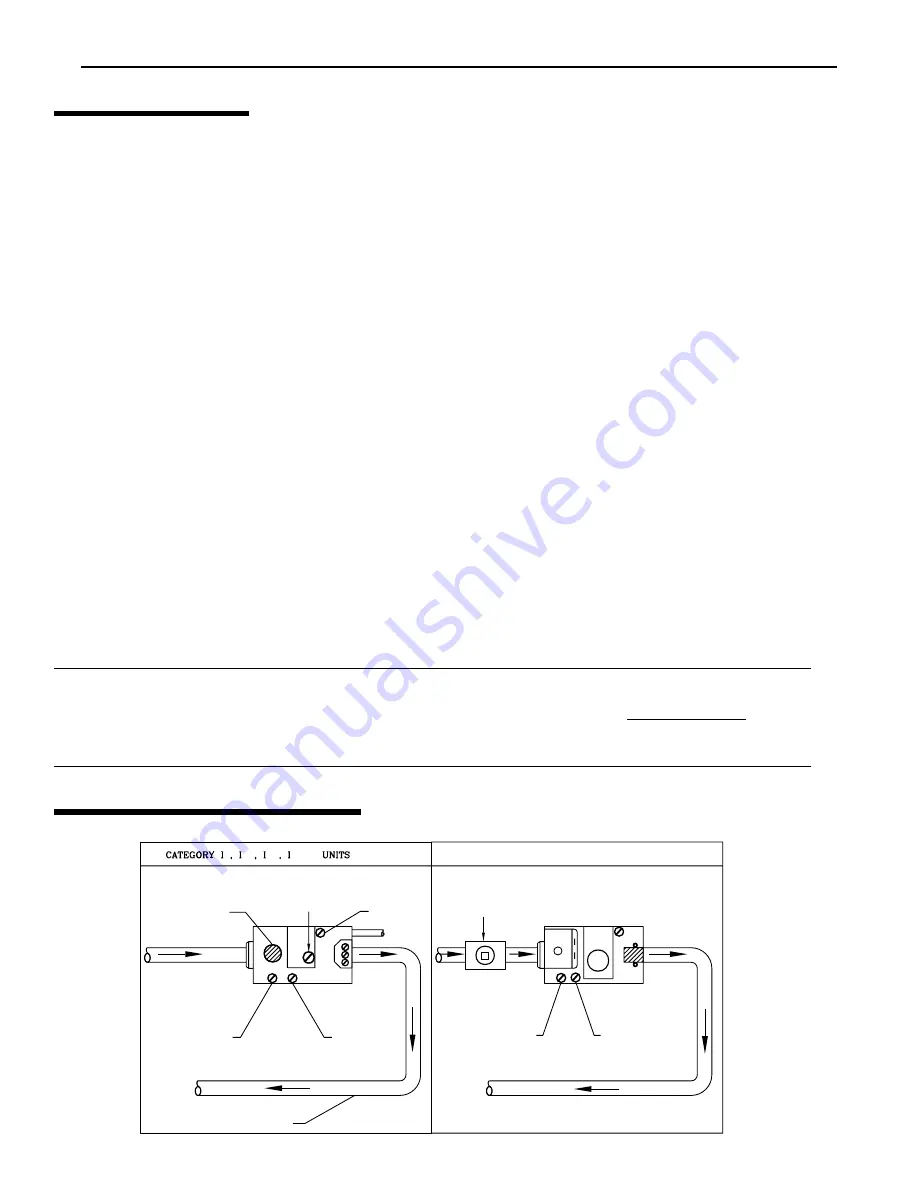

GAS CONTROL ASSEMBLY

Installation Section / Commissioning

17

CATEGORY I

2E+

UNITS.

( ILLUSTRATION SHOWS MILLIVOLT VALVE )

( ILLUSTRATION SHOWS AUTOMATIC VALVE )

BURNER MANIFOLD

INLET PRESSURE

INLET PRESSURE

BURNER PRESSURE

ADJUSTER

GAS CONTROL

GAS PRESSURE

PILOT

KNCB

BURNER PRESSURE

GAS PRESSURE

ADJUSTER

ADJUSTER

PIPE

PILOT

2

3

2

3

E

P

B/P

Содержание PacFab MiniMax 100

Страница 28: ...P N 471438 Rev A 2 4 2000 33 14 EXPLODED VIEW 23...

Страница 30: ...P N 471438 Rev A 2 4 2000 25 NOTES...

Страница 31: ...Rev A 2 4 2000 P N 471438 26 NOTES...