CONFIGURATION

PERMISSIBLE SUPPLY

POSSIBLE OUTPUT

EXPLANATORY NOTES

VOLTAGE RANGE

SIGNALS

EICT/EICTM ONLY

The 60Vdc supply voltage is permissible

(NO OPTION CARD FITTED)

VPOS = +10 to +60Vdc

+0.5 to +4.5Vdc

ONLY when NO option card is fitted

EICT/EICTM WITH CM (CURRENT)

VPOS = +10 to +30Vdc

4-20mA

Current is sourced to ground with a

OPTION CARD FITTED

compliance voltage of VPOS -4V

-10 to 0Vdc

VPOS = +10 to +30Vdc

-5 to 0Vdc

An internal negative rail generator

(SEE NOTE A BELOW)

-5 to +5Vdc

enables output voltages of zero

EICT/EICTM WITH VM (VOLTAGE)

-2.5 to +2.5Vdc

and below to be achieved.

OPTION CARD FITTED

0 to +5Vdc

-10 to +10Vdc

VPOS = +13.5 to +30Vdc

-7.5 to +7.5 Vdc

The supply voltage must be at least

(SEE NOTE A BELOW)

0 to +10 Vdc

+13.5V to obtain these output voltages

EICT/EICTM WITH PWM

TTL level signal with

Logic High = 4.5Vdc ±0.5Vdc

(PULSE WIDTH MODULATION)

VPOS = +10 to +30Vdc

10-90% duty cycle

Logic Low = <0.4Vdc

OPTION CARD FITTED

Output frequencies can be selected from

100Hz, 130Hz, 310Hz and 1KHz

EICT

Installation and set-up guide

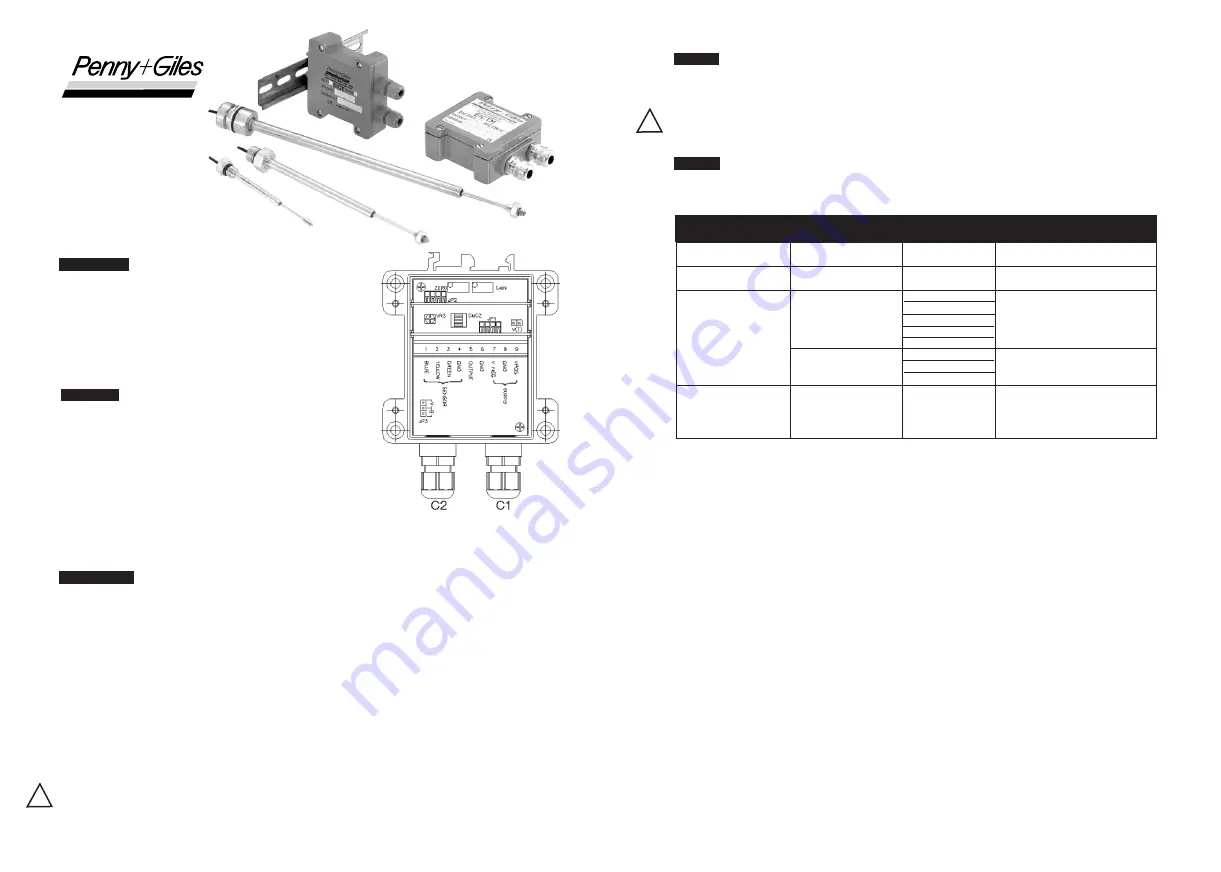

DESCRIPTION

Models

EICT

&

EICTM

are specialist driver/signal conditioning units for

Penny + Giles'

ICT

and

SLT

range of linear displacement transducers.

These modules incorporate a high performance circuit that drives the

transducer and provides a choice of output signals, with zero and gain

adjustment for simple user configuration. The module can be supplied

in a choice of enclosures, with sealing to IP66 (EICT) or IP68 (EICTM)

protection. For the full product specifications, refer to the

EICT/EICTM

data sheets in the relevant transducer product brochure.

MOUNTING

•

The

EICT

module has a dual mounting option. It can be mounted

on a bulkhead within 10m of the transducer, by using 4 x M5 cap

head screws, 28mm long (minimum) through the mounting holes

that are located under the housing lid. The recommended screw

tightening torque is 4Nm. Alternatively, the rear box detail is

suitable for mounting on a DIN EN50022 or EN50035 rail.

EICT module is rated to IP66 environmental protection.

•

The

EICTM

module can only be mounted on a bulkhead exactly as

the EICT module.

EICTM module is rated to IP68 environmental protection.

•

The user should also ensure that the rubber seal is properly located in the lid groove prior to re-fitting the

lid after setup. Recommended tightening torque for the lid screws is 2Nm.

WIRING NOTES

•

These modules will only drive the ICT or SLT transducers correctly when an appropriate Sensor

Calibration Module Card

(SCMC)

is fitted on header

JP1

. The SCMC is supplied within the packaging for

the displacement transducer.

•

EICT module

- The supply, transducer and output connections are routed through two IP66 rated cable

glands that can accommodate cable diameters of between 2.5 and 6mm.

•

EICTM module

- The supply, transducer and output connections are routed through two IP68 rated cable

glands that can accommodate cable diameters of between 3 and 8mm.

•

The user should ensure that the cable glands are tightened sufficiently to ensure cables are clamped and

sealed.

•

Users should also ensure adequate sealing of the opposite end connections on supply, transducer and

output cables to ensure moisture cannot migrate down the inside of the cables into the

EICT/EICTM

module.

•

Connections are made to a screw terminal block on the

EICT/EICTM

circuit board.

•

The enclosure is not connected internally to ground, so it can be mounted on a chassis carrying a voltage

potential other than 0Vdc.

•

If in doubt about wiring to ground, consult your systems engineer.

•

It is essential that Steps 1 to 7 are completed before connecting a power supply to the

EICT/EICTM. Incorrect connections may destroy the EICT/EICTM on power up.

INNOVATION IN MOTION

Fig.1

Step 1

Remove the four retaining screws to release the lid from the enclosure base. Note the position of the gasket in

the lid. Identify the Sensor Calibration Module Card

(SCMC)

supplied with the transducer. Insert the

SCMC

card into position

JP1

. (See Fig.1)

Important note: Do not remove the Sensor Calibration Module Card (SCMC) after the calibration

procedure, to ensure proper function of the sensor system!

Step 2

Refer to the Power Supply Voltages v Output Options Matrix chart below to establish the MAXIMUM and

MINIMUM power supply voltage parameters.

CAUTION

!

CAUTION

!

Note A - Dual supply:

•

The

EICT/EICTM

, with or without option cards fitted, requires only a single supply voltage connected

between

GND

and

VPOS

.

When the

VM

(Voltage Module) option card is used, an internal negative rail generator enables zero and

negative output voltages to be achieved.

•

In some situations an external negative supply in the range -10V to -30Vdc may be available (e.g. where

the EICT is being used to replace an earlier model of signal conditioner). It is permissible to connect this

voltage to

VNEG

, in which case the internal negative supply generator on the

VM

option card will be

disabled and current will be drawn from the external supply.

•

To obtain outputs of -10Vdc or -7.5Vdc, the external negative supply should be at least -13.5Vdc.

Note B - Adjustment range:

•

Zero pot approximately 20 turns. Adjustment range = -10% to +60% of nominal sensor range.

•

Gain pot approximately 20 turns. Adjustment range = +40% to +110% of nominal sensor range.

•

Minimum sensor range is 50% of nominal sensor range.

Unscrew the cable glands

C1

&

C2

. (See Fig.1). See note [4] regarding cable diameters.

Single Supply

- Pass the power supply cable through gland

C1

into

'SUPPLY'

zone on the

EICT/EICTM

board.

Connect the power supply lead carrying the most POSITIVE potential (e.g. +24Vdc) to Terminal 9

[VPOS]

.

Connect the power lead carrying 0V to Terminal 8

[GND]

.

Dual Supply

- As Single Supply, BUT, connect most negative power lead (e.g. -15V) to Terminal 7

[VNEG]

. See

note [1] for 4-20mA output.

A power supply cable screen can be connected to Terminal 6

[GND]

. This is recommended but optional.

Consult your systems engineer if other options required.

Firmly tighten cable gland lock nut

C1

.