17

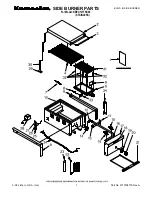

Pic. 11. Installation of burner.

Pic. 12. Lifting eye.

4.2.

Connecting the feeder

•

Attach with joint flexible pouring pipe, long enough to connect with upper part of the feeder,

no less however than 30 cm from vertical pouring axis of burner. Second part of flexible pipe

insert onto vertical pipe of chimney for pouring fuel of burner and tighten it with a band.

•

Insert lower part of feeder pipe in fuel hopper, remember that opening for granulate

must be directed upwards.

•

Fill the hopper with fuel. Certificate for fuel should be made available by the seller.

Specification of fuels is shown in Table 1.

•

Connect feeder to the control cabinet with electrical wire providing power to feeder (see

electrical scheme).

•

In case when oven or boiler does not have its own STB protection, a capillary thermostat

with fastener should be added to the set. A capillary sensor should be installed permanently

in water coat of boiler, together with temperature sensor of boiler.

4.3.

Connecting the controller

After proper installation of the burner in boiler’s wall, the wire of a multicoupler should be attached

to proper socket on the right side of burner..

ATTENTION!

The feeder should be positioned at angle

no bigger than 45° in relation to the floor.

2

3

1

Содержание M-line M350

Страница 1: ...1...

Страница 2: ......

Страница 3: ......

Страница 4: ......

Страница 13: ...9 Pic 3 Dimensions of M350 burner Pic 4 Dimensions of M500 burner...

Страница 31: ...27 10 REPORTS 10 1 First start up report Table 9 First start up report template...

Страница 32: ...28 10 2 Inspection report Table 10 First inspection report template...

Страница 34: ...30 12 NOTES...

Страница 35: ...31 NOTES...

Страница 36: ...32...