Special safety rules for wood lathe

WARNING: DO NOT USE YOUR WOOD LATHE

BEFORE IT IS FULLY ASSEMBLED AND INSTALLED

IN ACCORDANCE WITH THE INSTRUCTIONS.

1. For your own safety, read the whole

operating instructions before using the lathe.

2. Do not assemble a split workpiece.

3. Use the lowest speed when starting a new

workpiece.

4. Read the warning label attached the wood

lathe.

5. When turning a workpiece, always roughen the

wood to a round shape at slow speed. If the

lathe runs so fast that it vibrates, there is a risk

of the workpiece being thrown or the tool being

snatched from your hands.

6. Always rotate the workpiece manually before

turning on the engine. If the workpiece hits the

tool support, it can split and be thrown out of

the lathe.

7. Do not allow the turning tools to bite into the

wood. The wood can split or be thrown out of

the lathe.

8. Always place the tool at rest above the center

line of the lathe when shaping a workpiece.

9. Do not use the lathe if it rotates in the wrong

direction. The workpiece must always rotate

towards you.

10. Do not use the lathe if it rotates in the wrong

direction. The workpiece must always rotate

towards you.

11. Always place the tool at rest above the center

line of the lathe when shaping a workpiece.

12. Do not use the lathe if it rotates in the wrong

direction. The workpiece must always rotate

towards you.

13. Before attaching a workpiece the faceplate,

make it as round as possible. This minimizes

the vibrations while the piece rotates. Always

secure the workpiece securely to the faceplate.

Failure to do so may result in the workpiece

being thrown out of the lathe.

14. Position your hands so that they do not slip on

the workpiece.

15. Remove all loose hooks in the workpiece before

mounting it between the centers or on the front

plate.

16. Leave the work area only after the lathe’s motor

has stopped completely.

17. Hang your turning tools on the stand beyond

the rear end of the turning spindle. Do not place

them on the bench so that you have to extend

over the rotating workpiece to reach them.

18. Hold on and always keep control of the

turning tool. Take special precautions when

working on a part of the workpiece where pegs

or holes are located.

19. Make sure that the workpiece is stabile before

removing it from the lathe.

Adjustments

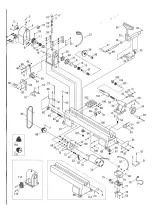

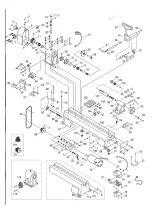

Assembly

Be sure to position the tool so that there is an

open space directly under the engine to protect the

chips from building up and soiling the engine fan

housing. For general work (portable) on table top,

mount the four rubber feet (50).

Tool stand (52):

Using the two screws (52-1), you can mount the

tool stand on the back of the lathe.

The stud (9,10,11,12):

Turn the stud’s handwheel (3) clockwise to extend

the stud doll spindle. Turn it counterclockwise to

retract it. The shaft (7) of the stud dock is locked

at its current extension. Be sure to release the lock

before attempting to adjust the spindle sleeve

extension. The handle (34) locks the back piece in

its current position on the stand next to the

mandrel. Detach to move the stud dock assembly

closer or farther from the spindle dock. To adjust

the clamp in the stand, slide the stud out of the

stand and turn the nut located on the bottom of the

stud.

Work lamp (28):

Use only a 40 watt or smaller light bulb in the work

light. Position the lamp to prevent chips from

accumulating in the lamp housing. Lamp not

included.

Power supply of the lathe:

The power switch (39-2) controls the power to the

motor. Switch the switch to the ON position and

the engine will start. The lathe begins to rotate

and reaches its full speed within a few seconds.

The time it takes for the motor to reach its full

speed depends on the size of the workpiece and

the speed setting. Switch the switch to the OFF

position to stop the lathe. Wait for the tool to come

to a complete stop before performing any further

operations.

The speed control knob (39-1) determines the

speed at which the lathe rotates. Turn the knob

clockwise to increase speed control and

counterclockwise to decrease speed. Always set it

to the lowest setting before turning the lathe. The

turning speed is digitally indicated by the monitor

(25).

Содержание 494213

Страница 1: ...Tr svarv 450 mm Wood lathe 450 mm Item No 494213...

Страница 5: ......

Страница 8: ......

Страница 12: ......

Страница 15: ......

Страница 16: ...Verktygsboden Erfilux AB K llb cksrydsgatan 1 SE 507 42 Bor s Verktygsboden Bor s Sweden 0120504 03...