SECTION III

–

REASSEMBLY

3-1.

ROTATING ELEMENT.

(See Figure 1)

Reassemble as follows:

a. Coat the shaft (6) lightly with oil.

b. Place impeller key (32) in shaft keyway and one

impeller retaining ring (2A) in groove in shaft.

c. Align impeller (2) on shaft and install with an arbor

press or brass tubular sleeve and hammer until impeller

hub contacts the impeller retaining ring. Install the

second impeller retaining ring (2A). Guard against

bending shaft. When assembled, the impeller vanes

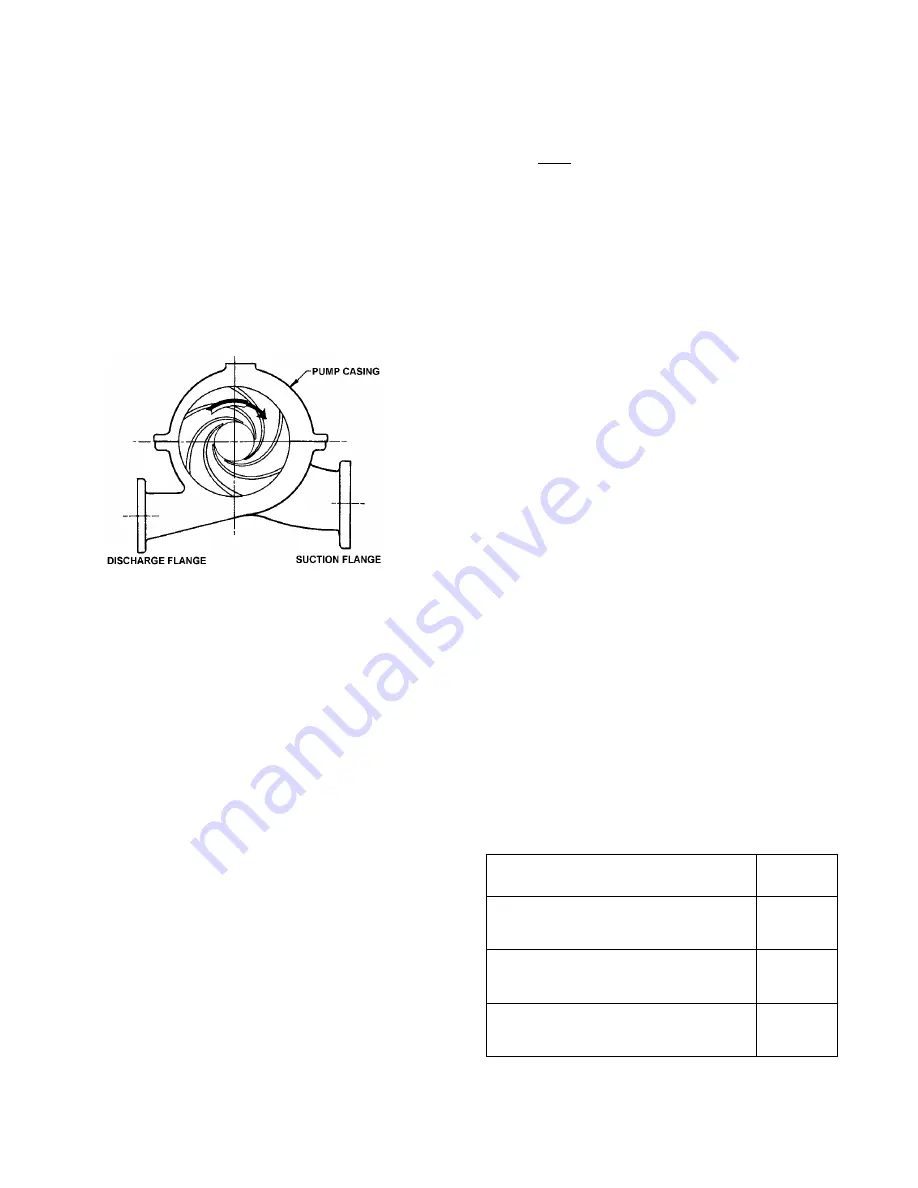

must rotate in the proper direction, (See Figure 3).

FIGURE 3. VANE POSITION FOR PROPER ROTATION

d. Locate casing rings (7) on impeller.

e. Lightly lubricate the O-rings on the O.D. of the

mechanical seal stationary elements (65), and install

stationary elements into glands (17). Install the gland O-

rings (119B). Place these assemblies over the shaft.

g. Slide bearings (16 &18) onto the shaft but do not

tighten bearing set screws at this time.

h. Install coupling key (46); and assemble coupling half

on the shaft and tighten the setscrews.

3-2.

PUMP.

Complete the assembly of pump as

follows:

a. Use factory supplied casing gasket (73A) or use the

upper casing (1B) as a template to cut a casing gasket

(73A) from 1/64 inch Vellumoid (SAE P3313B). It is very

important that specified material and thickness be used

for casing gasket. Machined surfaces of both casings

must be perfectly clean and free from burrs and nicks.

b. Affix the new casing gasket to lower casing (1A). Trim

the gasket carefully with a sharp knife. The casing

gasket must seal against the gland. O-ring (119B).

c. Se the rotating element into lower casing. Position the

casing rings (7) so that the dowel pins engage in slots in

the lower case split surface.

d. Center the shaft in the lower case so that the

dimension from the shaft shoulder at the mechanical

seal (80) to the end of the lower casing (1A) is the same

at each end of the pump.

e. Install and tighten the two cap screws attaching the

outboard bearing (18) to the lower case (1A).

f. Tighten the setscrews holding the inner race of the

outboard bearing (18) to the shaft (6). Replace the

protective cap which covers the outboard end of the

shaft.

g. Carefully locate the upper casing on the lower and

install the two dowel pins. Install and tighten the cap

screws working from the center of the casing to each

end. Tighten to the torque values in Table II. If any cap

screws require replacement, use only parts with equal or

greater tensile strength. Rotate shaft by hand to check

that it turns freely.

h. Replace all plugs removed during disassembly.

i. Lubricate the bearings.

NOTE

It is very important to provide proper lubrication and

to keep bearings clean. Frequency of lubrication must

be determined by experience, as it depends upon

bearing

size,

speed,

operating

conditions

and

environment. Table III should be used only as a guide for

re-lubrication.

TABLE III

GREASING FREQUENCY

SERVICE

GREASE

EACH

Normal, 8-hour day operation. Room

free of dust and damaging

atmosphere.

6 Months

Sever, 24-hour day operation. Room

with moderate dust and/or damaging

atmosphere, or outdoor service.

1 Month

Light, approximately 10-hour week.

Room relatively free of dust and

damaging atmosphere.

1 Year

5