Page 5

Technical Description

Basic Concept

The i-Flow is a modular range of Carbon Molecular Sieve (CMS) nitrogen gas

generators, that operate based on Pressure Swing Adsorption (PSA) technology.

Essentially this requires two separate columns or “beds” of granular carbon pellets.

The unit requires a compressed air supply to operate, ultimately works on very similar

principles to many standard air filtration / drying products. The inlet compressed air

is passed into the first “bed”, as the air passes across the carbon bed the oxygen is

adsorbed, allowing the nitrogen to carry on through the bed for collection and further

use. After a certain time the online carbon bed will become saturated with oxygen so

the control system will operate various valves to bring the second carbon bed online.

Whilst the second bed comes online, the first bed is vented to atmosphere to release

the adsorbed oxygen and regenerate the bed in preparation for the next cycle. This will

continue to alternate and repeat until the user stops consuming nitrogen.

Should the demand for nitrogen be less than the rated output flow, or indeed should

the demand stop, the generator will automatically go into ECO Mode and the front

panel LED will illuminate. In ECO mode the changeover of the columns is suspended

which will stop the consumption of inlet compressed air. The control system will

automatically detect when the demand resumes and the generator will start to produce

nitrogen again.

General Construction

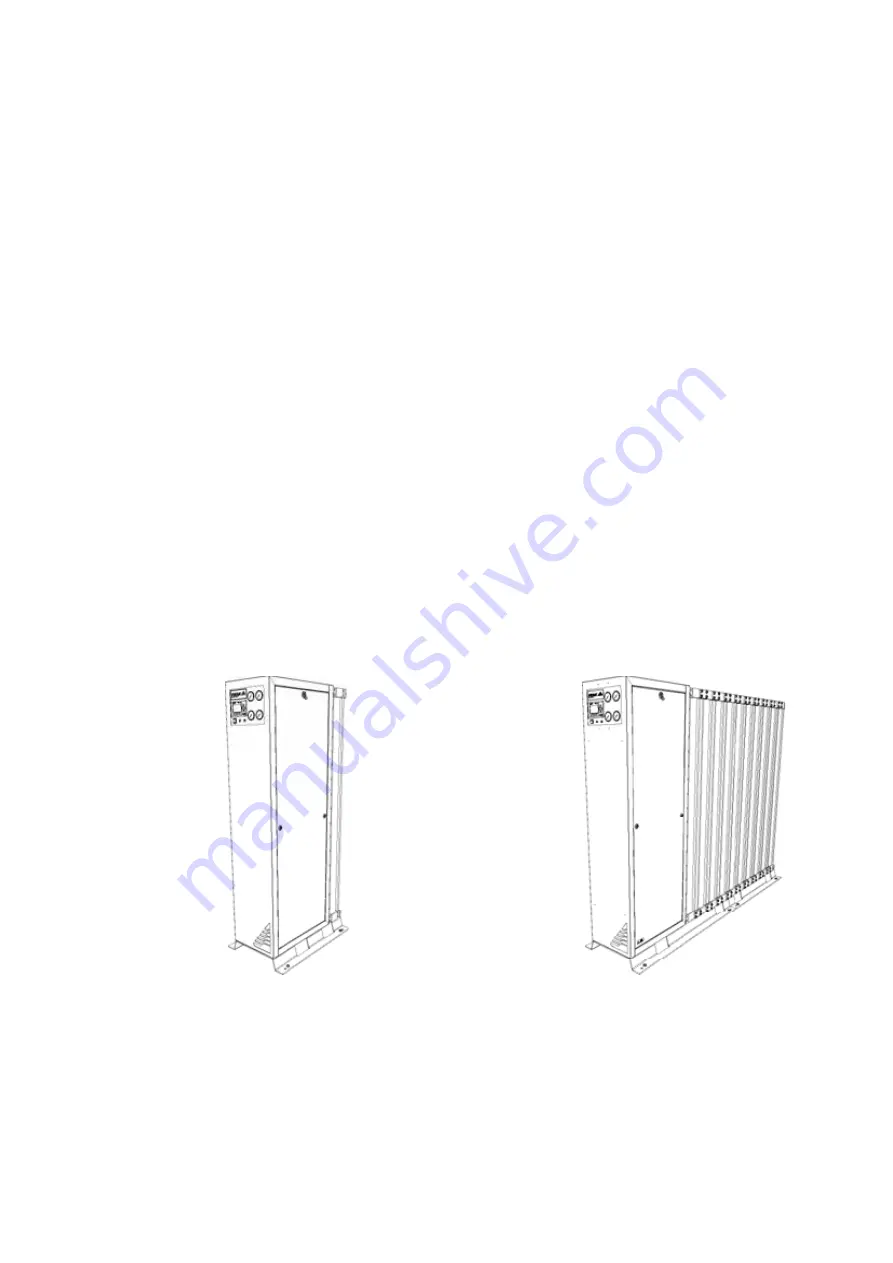

The range consists of 10 different product sizesm, demonstrated below:

The front end cabinet, control system and valves are consistent across the range. To

increase the outlet capacity, as you go up the range of generators, additional banks of

CMS columns will be added. (Note: for 6 to 10 banks additional vent valves and silenc-

ers are required and are fitted to the rear of the CMS columns)

Base unit with

minimum single

bank of dual

CMS columns.

Base unit with

maximum 10

banks of dual

CMS columns.