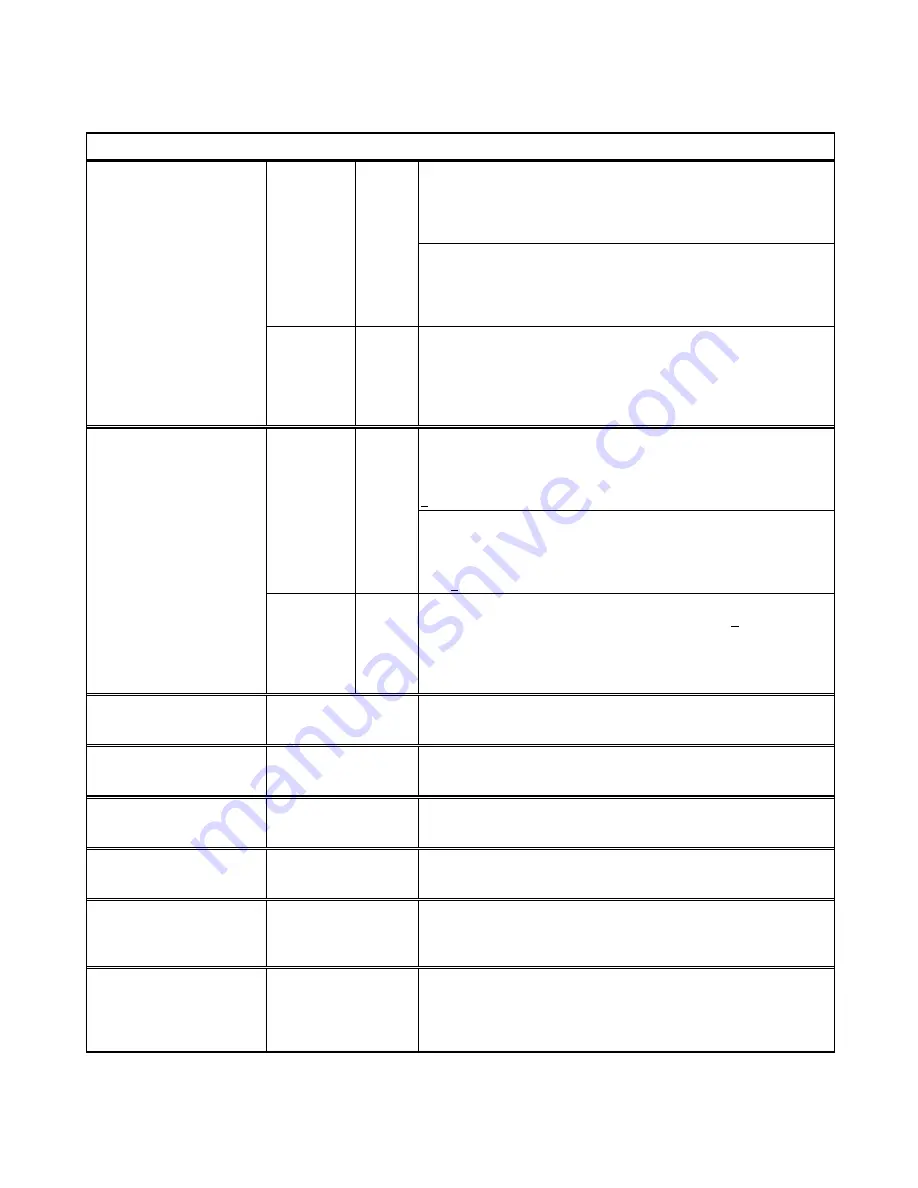

Page 13

CONCERN

ACTION

If the angle is less than 90

°,

locate the open stop bolt at the base of the rotating

insulator (Left hand side). Loosen the jam nuts on the stop bolt and turn the bolt

inward until the 90

°

angle is obtained. Proper adjustment of the switch in the

open position is accomplished when the moving contact or "beavertail" is at a

90

°

+3

°/-0°.

If the angle is more than 90

°,

locate the open stop bolt at the base of the rotating

insulator (Left hand side). Loosen the jam nuts on the stop bolt and turn the bolt

inward until the 90

°

angle is obtained. Proper adjustment of the switch in the

open position is accomplished when the moving contact or "beavertail" is at a

90

°

+3

°/-0°.

Is it in the 3

phase

arrangement?

If so then:

If the switch does not fully open to 90

°

make sure that the outboard bearing

traveled the complete 190

°

. If not, loosen the stop bolts and turn inward until the

90° opening can be obtain. If the outboard bearing does travel 190

°

and the

bearing is "pulling" the switch open, lenghen the trail radius crank by 1/4" until

90

°

opening can be obtained. For pushing the switch open, lengthening the trail

radius would also be necessary. (pg. 8 & 9)

If the beavertail is under 0

°,

locate the closed stop bolt at the base of the rotating

insulator (right hand side). Loosen the jam nuts on the stop bolt and turn the bolt

inward until the 0

°

flatness is obtained. Proper adjustment of the switch in the

closed position is accomplished when the moving contact or "Beavertail" is at 0

°

+4

°

parallel with the switch base.

If the beavertail is more than 0°, locate the closed stop bolt at the base of the

rotating insulator (right hand side). Loosen the jam nuts on the stop bolt and turn

the bolt outward until the 90

°

angle is obtained. Proper adjustment of the switch

in the closed position is accomplished when the moving contact or "beavertail" is

at 0° +4° parallel with the switch base.

Is it in the 3

phase

arrangement?

If so then:

Manually operate the single pole, driven by the outboard bearing to the closed

position. Verify the moving contact or "beavertail" is at a 0

°

+4

°

parallel with

the switch base. If the outboard bearing is "pushing" the switch closed, then

lengthen the offset rod by using the vernier adjustment until the +4

°

closing can

be obtained. For pulling the switch closed shortening the offset rod should be

necessary. (pg. 8)

Blade is too high in the jaw, not in

the centerline of the contact

springs

If the height is more than the suggested 5/8" off of the stop, lengthen the

assembly by turning the clevis clockwise in 1/2 turn increments until the correct

height is achieved.

Blade is too low in the jaw, not in

the centerline of the contact

springs

If the blade is driving into the stop creating a binding situation, shorten the

assembly by the turning the clevis counter-clockwise in 1/2 turn increments until

the correct height is achieved.

Switch will completely open, but

not completely close

Check the degree of angle between the interphase crank and the multi-angle

crank on the drive phase. Set to the degree angle indicated on the Control

Drawing Plan View.

Switch will completely close but

not completely open

Check the degree of angle between the interphase crank and the multi-angle

crank on the drive phase. Set to the degree angle indicated on the Control

Drawing Plan View.

Outside phase(s) will not

completely turn flat.

Typically, it is better to over travel the moving contact on the drive phase to the

m4 to allow for any lost motion once the remaining phases are

connected. This will allow these phases to fall within the 0 to -4 tolerance.

All three phases are inconsistant,

not working together.

Manually operate the switch to open and verify adjustment needs. Fine-tuning of

the new phase can be accomplished by slightly shortening or lengthening the

interphase rod. Use the vernier adjustment on the center phase to lengthen or

shorten the interphase pipe, depending on whether you need more opening or

closing. (pg. 9)

Trouble Shooting Guide

Blade isn't completely flat when

closed

If so then:

Is this at the

single pole

assembly level?

If so then:

Is this at the

single pole

assmebly level?

Blade doesn't open to 90 degrees