www.parweld.com

9

1. Open the Wire drum cover by pulling down and

out on the bottom of the cover

2. Unscrew the plastic retaining wheel from the end

of the spool holder shaft.

3. Position the wire spool so that it will rotate in a

direction when feeding so as to be de-reeled from

the bottom of the coil.

4. Slide the wire spool all the way onto the shaft and

refit the plastic retaining nut.

Note:- There is a friction brake on the reel hub

assembly to prevent the wire spool over running

when welding stops ensure the this is slackened to the

minimum setting. It can be adjusted by means of the

nut visible when the plastic nut is removed.

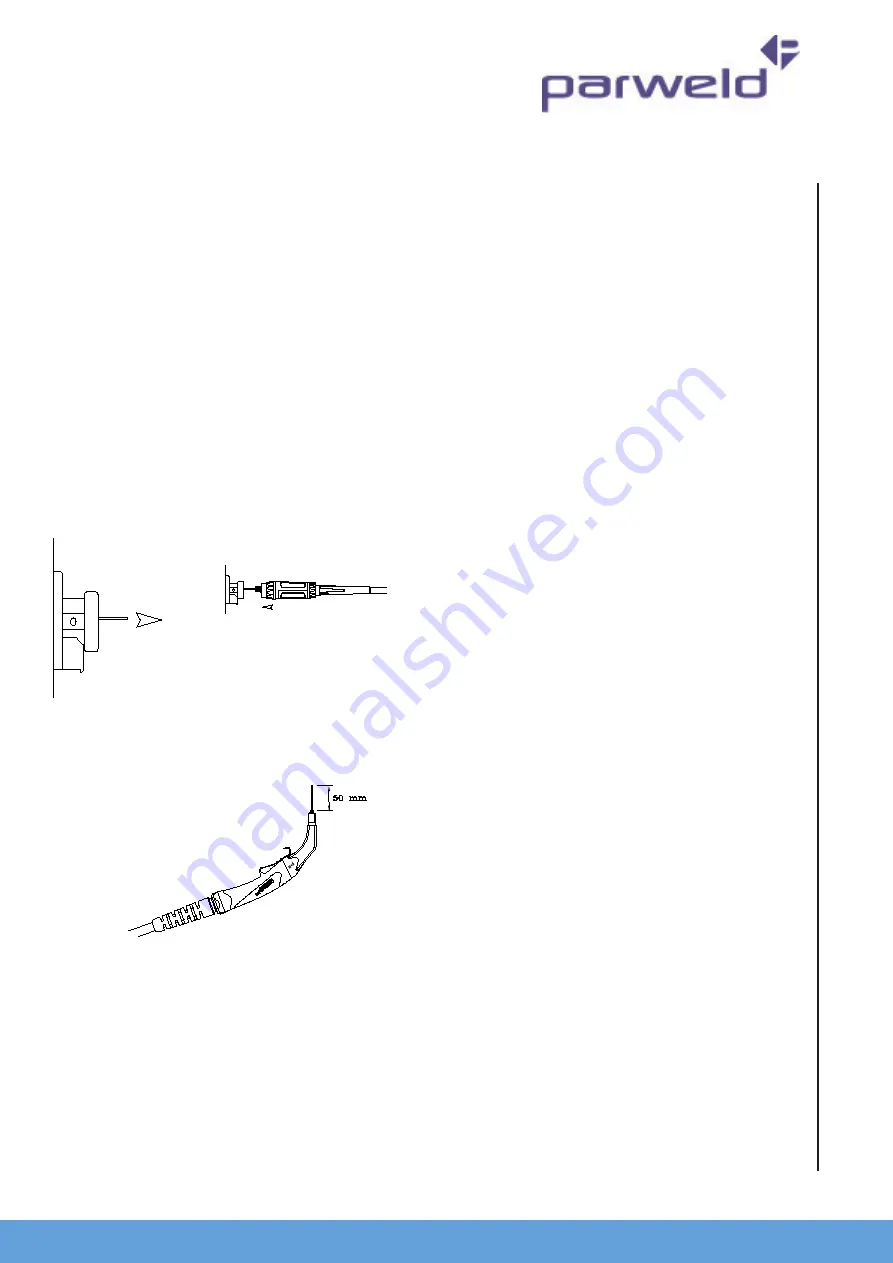

Fig 1

Fig 2

x

5.5 Output Polarity Connections

The welder, as shipped from the factory, is connected for electrode positive

(+) polarity. This is the normal polarity for MIG welding.

5.6 Changing drive roll sets

1. Turn off the power source.

2. Release the pressure on the idle rolls by swinging the adjustable

pressure arm down. Lift the cast idle roll assembly and allow it to sit

in an upright position.

3. Unscrew the plastic knob retaining the lower grooved drive roll and

side off the drive roller.

4. Ensure the wire size marked on the side of the feed roller matches

the wire size to be used.

5. Replace the drive rolls in reverse of the above procedure ensuring the

wire size to be used is marked on the outward facing side of the roller

as it is refitted.

NOTE: Be sure that the torch liner and contact tip are also sized to match

the selected wire size.

5.7 Welding wire installation

5. Turn the Spool until the free end of the electrode

is accessible. While securely holding the

electrode, cut off the bent end and straighten the

first six inches. (If the electrode is not properly

straightened, it may not feed properly through the

wire drive system Manually feed the wire from

the wire reel and through the wire guide and then

over the top of the wire feed rollers (ensure the

pressure arms are in the raised position.)

6. Continue to feed the wire through the outlet

guide until 20mm of wire is protruding from the

front of the machine torch connector.

7. Reposition the adjustable pressure arms to

there original position to apply pressure. Adjust

pressure as necessary.

Note the pressure arm should be adjusted in order to

give the minimum amount of pressure on the wire to

allow reliable feeding,

5.8 torch installation

Your Parweld MIG/MAG Welding Torch has been

supplied ready to weld. It has been supplied with

the standard consumables denoted in the product

brochure.

To connect the torch to the power source:-

1. Remove the tip adaptor and contact tip

2. Inch the wire from the exit of the wire guide on

the feed unit as Figure 1. Ensure that it does not

short out on any machine panels.

3. Carefully slide the electrode wire into the torch

liner and slowly locate the torch gun plug body

into the feed unit central connector and tighten

the gun plug nut as Figure 2

Note; To aid the initial location of a new torch and to

prevent damage to the gas nipple O-ring a very light

application of grease to the O Ring is beneficial.

4. Keeping the torch as straight as possible, use the

power source inch facility or torch trigger to feed

the electrode wire 50mm from the end of the liner

conduit.

5. Once the electrode wire has stopped, refit the tip

adaptor, diffuser, contact tip and gas nozzle.

6. Trim the electrode wire to within 5mm of the

face of the nozzle, this will facilitate jolt free arc

initiation.

7. Press the gas purge button and check the gas flow

is adequate for your application.

8. An inexpensive flow meter is available from

Parweld reference 806001.

9. If you are connecting a water-cooled torch ensure

you have the recommended water flow rate.

Note;- It is essential to ensure adequate flow of clean,

cool water to prevent irreparable torch failure, a

minimum of 1.2 l/min is recommended.

Parweld recommend the use of its XTS water

recirculation system designed specifically for use with

all water cooled MIG, TIG and Plasma welding torches.

The Parweld XTS recirculation equipment can be fitted

with a fail-safe flow protection device to prevent