www.parweld.com

Manganese steels

The effect on manganese steel of slow cooling from

high temperatures is enbrittlement. For this reason it

is absolutely essential to keep manganese steel cool

during welding by quenching after each weld or skip

welding to distribute the heat.

Cast iron

Most types of cast iron, except white iron, are

weldable. White iron, because of its extreme

brittleness, generally cracks when attempts are made

to weld it. Trouble may also be experienced when

welding white-heart malleable, due to the porosity

caused by gas held in this type of iron.

Copper and alloys

The most important factor is the high rate of heat

conductivity of copper, making preheating of heavy

sections necessary to give proper fusion of weld and

base metal.

Types of electrodes

Arc welding electrodes are classified into a number

of groups depending on their applications. There are

a great number of electrodes used for specialized

industrial purposes which are not of particular interest

for everyday general work. These include some low

hydrogen types for high tensile steel, cellulose types

for welding large diameter pipes, etc. The range of

electrodes dealt with in this publication will cover the

vast majority of applications likely to be encountered;

are all easy to use and all will work on even the most

basic of welding machines.

Metals being joined & electrode comments

Mild steel

6013 ideal electrodes for all general purpose work.

Features include outstanding operator appeal, easy

arc starting and low spatter.

10

O

pera

tIO

n

Mild steel

7014 all positional electrode for use on mild and

galvanized steel furniture, plates, fences, gates, pipes

and tanks etc. Especially suitable for vertical down

welding.

Cast iron

99% nickel suitable for joining all cast irons except

white cast iron

Stainless steel

318l-16 high corrosion resistance. Ideal for dairy work,

etc. On stainless steels.

6.3

TIG Welding guide

Controls used

2T/4T sets the trigger to momentary or latching for

longer welding runs.

Voltage adjustment knob, allows the adjustment of

the post gas flow time after welding stops.

Current adjustment knob which controls the output

current.

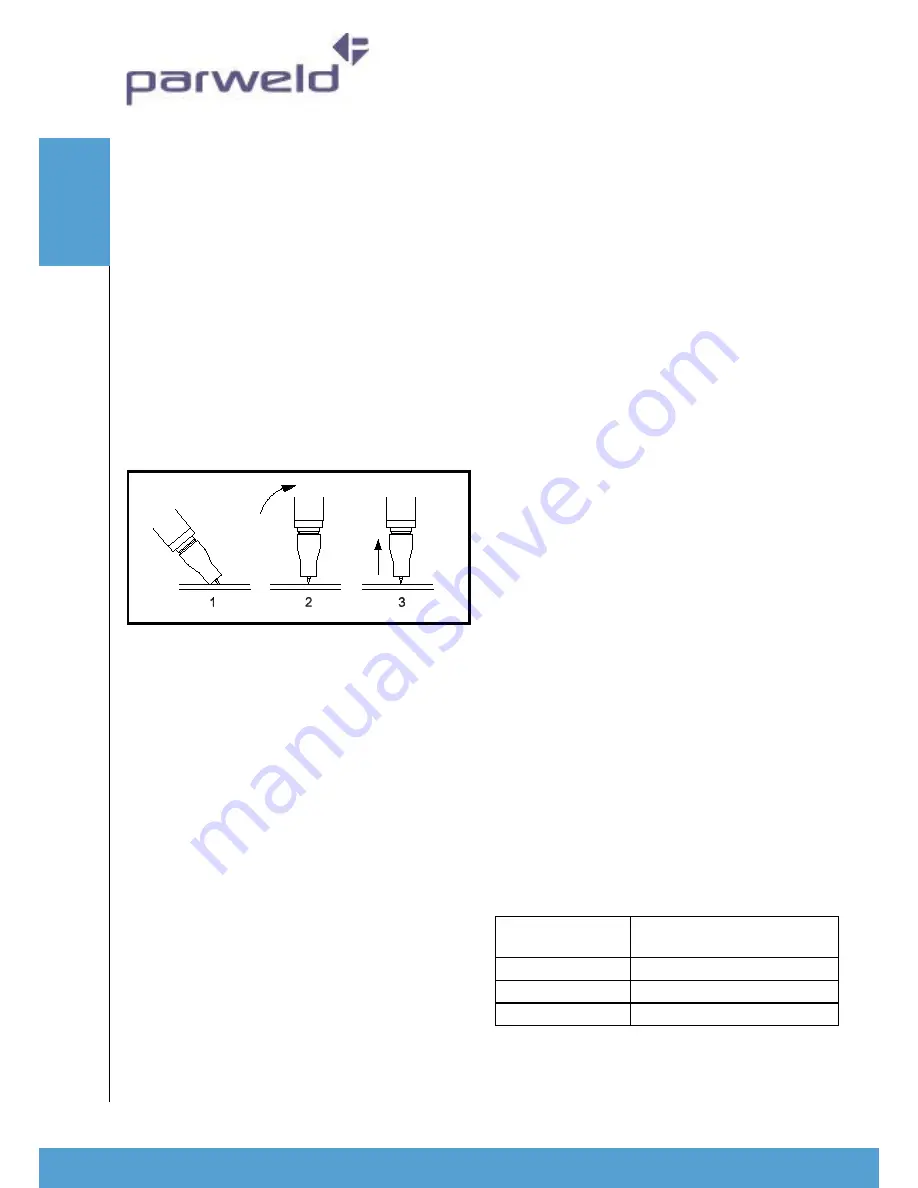

Torch starting in Lift TIG mode

Ensure the gas supply is switched on. Briefly contact

the tip of the tungsten electrode down onto the work

piece with the torch at around 70

0

from vertical,

depress the torch trigger to switch on the welding

power and the gas flow. Lift the torch up from the

work piece to draw out an arc. To prevent melting of

the end of the tungsten the machine will increase the

output current when it detects the rise in arc voltage

as the tungsten is lifted from the work piece. TO stop

welding release the trigger

Note in 4T mode the trigger should be release during

welding and then depressed briefly to stop the

welding process.

TIG welding guide ranges

Electrode

diameter

DC current (amps)

0.040” (1.0mm)

30 – 60

1/16” (1.6mm)

60 – 115

3/32” (2.4mm)

100 – 165

Содержание XTI-601 MP

Страница 1: ...INSTRUCTION MANUAL...

Страница 2: ...Operator Manual ISSUE 1 XTI 601 MP...