BASIC TIG WELDING GUIDE

Tig welding cable connection

Connect the TIG torch to the Negative terminal and the work

lead to the Positive terminal for direct current straight polarity.

Direct current straight polarity is the most widely used polarity

for DC TIG welding. It allows limited wear of the electrode

since 70% of the heat is concentrated at the work piece.

Connect the gas hose on the TIG torch to the gas outlet on

the front panel of the machine and the control lead plug to the

socket on the front panel of the machine.

Basic control setups

.

DC welding non pulse

Select DC current (7)

Select non pulse (16)

Select 2T trigger (8)

Select Tig mode (17)

Adjust pre-flow to mid range (3)

Adjust down slope to mid range (6)

Adjust post flow to mid range (15)

Adjust welding current to desired level (4)

AC welding non pulse

Select AC current (7)

Select non pulse (16)

Select 2T trigger (8)

Select Tig mode (17)

Adjust pre-flow to mid range (3)

Adjust down slope to mid range (6)

Adjust post flow to mid range (15)

Adjust welding current to desired level (4)

Adjust cleaning control to mid range (14)

Additional pulse settings

Set frequency to mid range (12)

Set pulse duration to mid range (13)

Set background current to mid range (5)

Select pulse option (16)

TIG welding guide ranges

Electrode diameter

dc current (amps)

0.040” (1.0mm)

30 – 60

1/16” (1.6mm)

60 – 115

3/32” (2.4mm)

100 – 165

Tungsten electrode types

Electrode type Welding application

colour

code

Thoriated 2%

dc welding of mild steel,

stainless steel and copper. Excellent arc

starting, long life, high current carrying

capacity.

Ceriated 2%

dc welding of mild steel, stainless steel,

copper, aluminium, magnesium and

their alloys longer life, more stable arc,

easier starting, wider current range,

narrower more concentrated arc.

Guide for selecting filler wire diameter

Filler wire diameter

dc current range

1/16” (1.6 mm)

20 - 90

3/32” (2.4 mm)

65 - 115

1/8” (3.2 mm)

100 - 165

3/16” (4.8 mm)

200-350

The filler wire diameter specified is a guide only, other

diameter wires may be used according to the welding

application.

Shielding gas selection

Alloy

shielding gas

Aluminium & alloys

argon

Carbon steel

argon

Stainless steel

argon

Nickel alloy

argon

Copper

argon

Titanium

argon

ROUTINE MAINTENANCE

The only routine maintenance required for the power supply is

a thorough cleaning and inspection, with the frequency

depending on the usage and the operating environment.

Warning

Disconnect primary power at the source before removing the

cover. Wait at least two minutes before opening the cover to

allow the primary capacitors to discharge.

To clean the unit, remove the screws securing the outer

cover, lift off the outer cover and use a vacuum cleaner to

remove any accumulated dirt and dust. The unit should also

be wiped clean, if necessary; with solvents that are

recommended for cleaning electrical apparatus.

TROUBLE SHOOTING

TIG welding problems

Weld quality is dependent on the selection of the correct

consumables, maintenance of equipment and proper welding

technique.

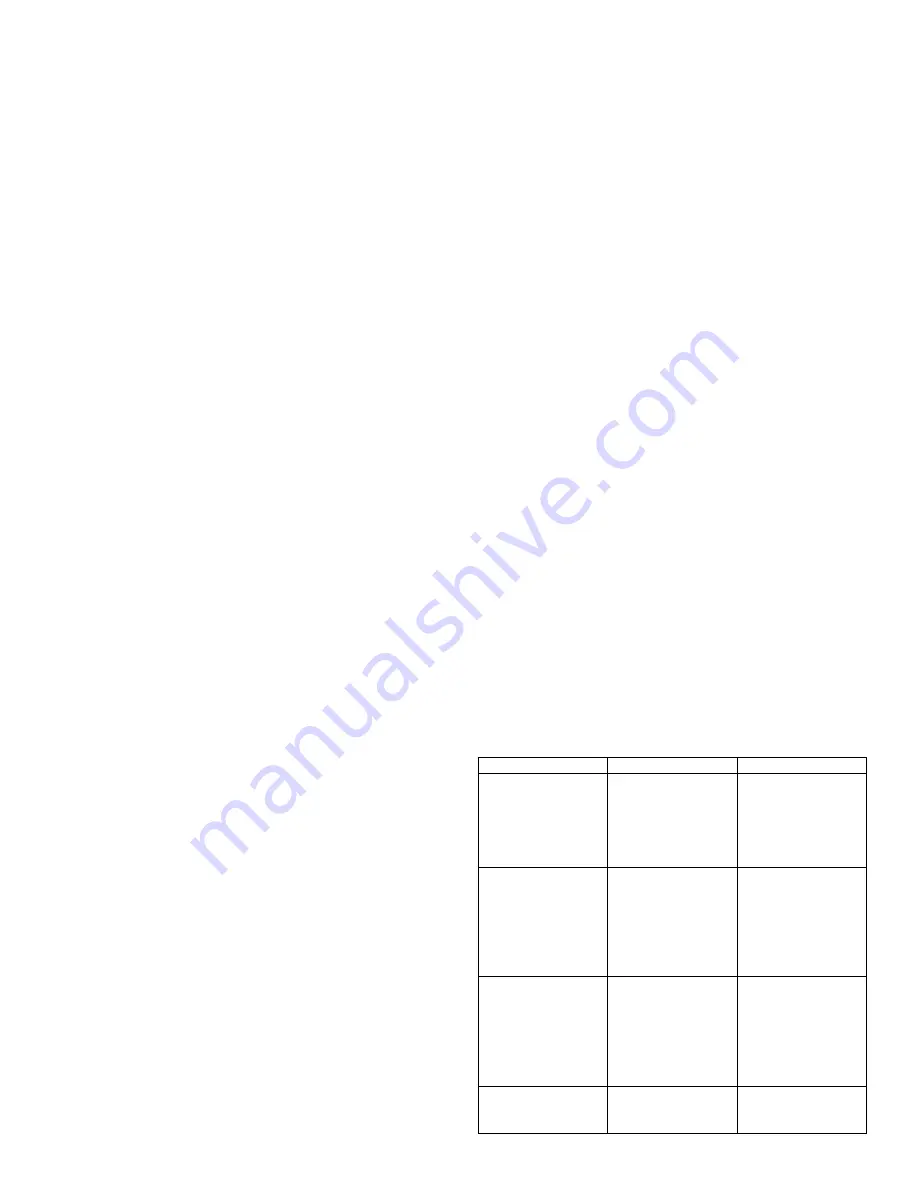

Description Possible

cause Remedy

Excessive bead

build up or poor

penetration or

poor fusion at

edges of weld

Welding current is

too low

Increase weld

current and/or

faulty joint

preparation

Weld bead too

wide and flat or

undercut at edges

of weld or

excessive burn

through

Welding current is

too high

Decrease weld

current

Weld bead too

small or

insufficient

penetration or

ripples in bead are

widely space apart

Travel speed too

fast

Reduce travel

speed

Weld bead too

wide or excessive

bead build up or

Travel speed too

slow

Increase travel

speed