Controls

The basic principle behind the controls needed while the

machine is running is that the operator should not need

to release his grip on the handle. Therefore, all the con-

trols are gathered together on the rear handle – for both

safe and comfortable operation.

The size and the shape of the controls make them

easy to operate with thick gloves on – gloves should

always be used for cutting operations.

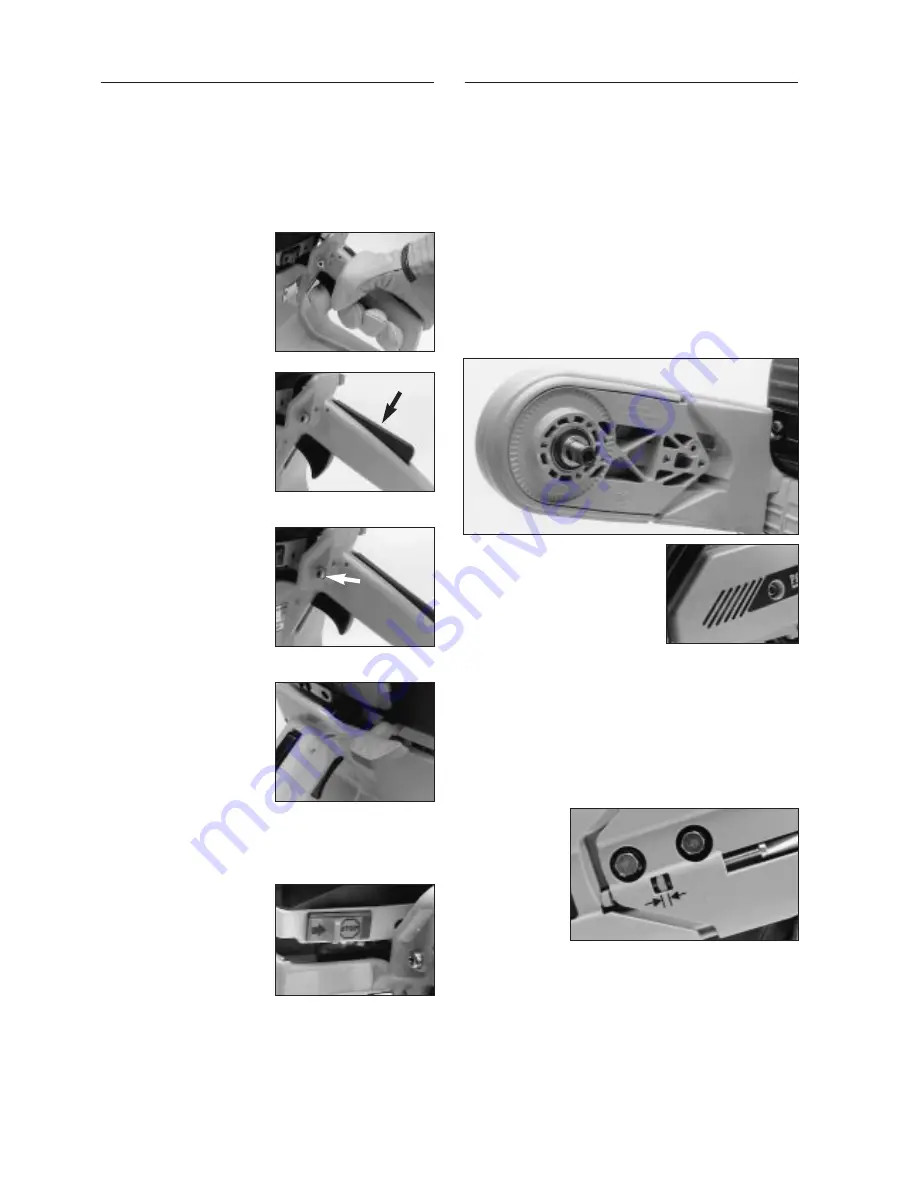

Throttle control

The throttle control has

been thoroughly tested.

The spring-loaded counter-

balance, its stroke, design

and precise positioning are

all optimised for best

“finger-tip comfort”.

Throttle trigger lockout

The throttle control is block-

ed in the idling position – a

safety device to prevent

accidental acceleration. The

inhibitor, on the upper face

of the handle, is released

when the driver grasps the

handle.

Starting throttle catch

The throttle control can be

locked in a partially open

setting which ensures the

correct throttle opening for

starting, with either a cold

or warm engine. As soon as

the throttle control is pres-

sed, the catch is released.

Choke

On the K950/K1250 Active,

the choke control is pulled

outwards, a more easily

noticeable indication that

the choke is engaged. The

choke control does not act

on the throttle shutter;

instead, the partial-throttle

setting is governed by the

starting throttle catch during

start-up.

Stop control

The stop control can be

operated with the thumb

without the operator having

to release the handle. The

control cuts the ignition.

8

Cutting unit

Belt drive

The cutter blade on the K950/K1250 Active, as on most

other Partner cutters, features one drive belt leading

from a pulley on the crankshaft to the pulley on the

spindle shaft. This design has the multiple advantages of

simplicity, reliability and low weight.

It is also important from the safety viewpoint. If the

cutter blade comes to a sudden stop, the drive belt will

slip and allow the engine to come to a halt more slowly.

The cutter arm is split to permit convenient belt replace-

ment and adjustment of belt tension.

Fully sealed transmission casing

Large machines like the K950 and K1250 Active are

often used for wet-cutting operations. Water on the belt

functions as a lubricant but also increases the risk of

belt slip. These machines are therefore equipped with a

sealed casing that prevents

water from reaching the belt.

Dust is also kept away from the

belt, thus reducing wear. In order

for the transmission to be suffici-

ently cooled, the casing features

cooling-air vents at the clutch.

Semi-automatic belt tensioning

Opinions as to what is the “correct” belt tension vary

from one operator to another. Partner’s semi-automatic

belt tensioning system solves this problem – a standard-

ised spring provides the correct tensioning force.

In precisely controlled experiments in the laboratory,

Partner has computed the optimum belt tension which

gives the belt maximum service life allied to perfect

application pressure before it slips against the pulley.

Belt tension

has to be ad-

justed occasion-

ally owing to

stretching and

wear of the belt.

This is done

quickly in three

stages.

Drive belt

The drive belt in a cutting machine is subjected to se-

vere and uneven loads and sometimes also to immense

load peaks. The drive belt also operates on relatively

small-diameter pulleys, which imposes particular

demands on the belt. To the naked eye, original-specifi-

cation Partner belts may look like any other drive belt,

but they are specially designed for their specific func-

tion. The belt-tensioning rating, which is determined by

the adjustment spring, is tested using genuine Partner

belts.