42

GB

• Wear safety goggles and a respirator when working with

the compressed air pistol. Dusts are harmful to health! In-

juries can be easily caused by foreign objects and blown

away parts.

• Do not blow at people with the blow-out pistol and do not

clean clothes while being worn. Danger of injury!

Safety warnings when using spraying attach-

ments (e. g. paint sprayers)

• Keep the spray attachment away from the compressor when

filling so that no liquid comes into contact with the compressor.

• Never spray in the direction of the compressor when using

the spraying attachments (e.g. paint sprayers). Moisture can

lead to electrical hazards!

•

Do not process any paints or solvents with a flash point be-

low 55 °C. Risk of explosion!

• Do not heat up paints or solvents. Risk of explosion!

• If hazardous liquids are processed, wear protective filter

units (face guards). Also, adhere to the safety information

provided by the manufacturers of such liquids.

• The details and designations of the Ordinance on Hazard-

ous Substances, which are displayed on the outer packaging

of the processed material, must be observed. Additional pro-

tective measures are to be undertaken if necessary, particu-

larly the wearing of suitable clothing and masks.

• Do not smoke during the spraying process and/or in the

work area. Risk of explosion! Paint vapours are easily com-

bustible.

• Never set up or operate the equipment in the vicinity of a fire

place, open lights or sparking machines.

• Do not store or eat food and drink in the work area. Paint

vapours are harmful to your health.

• The work area must exceed 30 m³ and sufficient ventilation

must be ensured during spraying and drying.

• Do not spray against the wind. Always adhere to the regula-

tions of the local police authority when spraying combustible

or hazardous materials.

• Do not process media such as white spirit, butyl alcohol and

methylene chloride with the PVC pressure hose. These media

will destroy the pressure hose.

• The work area must be separated from the compressor so that

it cannot come into direct contact with the working medium.

Operation of pressure vessels

• Anyone who operates a pressure vessel must keep this in

good working order, operate and monitor it correctly, per-

form the necessary maintenance and servicing works imme-

diately and implement safety measures as required accord-

ing to the circumstances.

• The regulatory authority can instruct necessary monitoring

measures in individual cases.

• A pressure vessel must not be operated if it exhibits a defect

that poses a danger to personnel or third parties.

• Check the pressure vessel for rust and damage each time

before use. The compressor shall not be operated if the pres-

sure vessel is damaged or rusty. If you discover damage,

please contact the customer service workshop.

Keep these safety instructions in a safe place.

Residual risks

Comply with the stipulated maintenance and safety instructions

in the operating instructions.

Remain attentive at all times when working, and keep third par-

ties at a safe distance from your work area.

Even when the device is being used properly, there will always

be certain residual hazards that cannot be completely ruled

out. The following potential hazards can arise due to the type

and design of the device:

• Unintentional starting up of the product.

• Damage to hearing if the stipulated hearing protection is not

worn.

• Dirt particles, dust etc. can get irritate the eyes or face de-

spite wearing safety goggles.

• Inhaling swirled up particles.

m

Warning!

This power tool generates an electromagnetic field during op-

eration. This field can impair active or passive medical implants

under certain conditions. In order to prevent the risk of serious

or deadly injuries, we recommend that persons with medical

implants consult with their physician and the manufacturer of

the medical implant prior to operating the power tool.

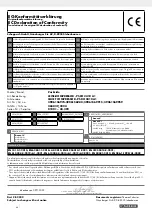

7. Technical data

Mains connection ................................................ 230 V∼ 50 Hz

Motor power ..................................................................1500 W

Operating mode .......................................................................S1

Compressor speed .....................................................2850 min

-1

Pressure vessel capacity ..........................................approx. 24 l

Operating pressure .............................................approx. 10 bar

Theo. intake capacity .................................... approx. 257 l/min

Effective delivery quantity at 7 bar .............. approx. 103 l/min

Effective delivery quantity at 4 bar .............. approx. 141 l/min

Effective delivery quantity at 1 bar .............. approx. 180 l/min

Sound pressure level L

PA

.................................................... 68 dB

Sound power level L

WA

....................................................... 82 dB

Uncertainty K

PA

/

WA

...............................................................3 dB

Protection category ...............................................................IP30

Device weight ....................................................... approx. 24 kg

Max. altitude (above mean sea level) ...........................1000 m

The noise emission values have been determined in accord-

ance with EN ISO 3744:1995.

Wear hearing protection.

Excessive noise can result in a loss of hearing.

8. Before commissioning

• Open the packaging and carefully remove the device.

• Remove the packaging material, packaging and transport

safety devices (if applicable).

• Check that the delivery is complete.

• Check the device and accessory parts for transport damage.

• If possible, keep the packaging until the end of the warranty

period.

Содержание PSKO 2410 A1

Страница 3: ...2 15 10 13 6 12 11 5 16 4 7a 7 14 3 5 5b 5a 1 1 7 6 5 8 2 3 4 14b 14a 14 13 12 9 10 11 7b...

Страница 4: ...6 4d 4 8 4a 4c 4d 7 9 9c 9a 9b 8 9 4a 4b 4c 4d...

Страница 28: ...24 BG 1 25 2 26 3 1 9 26 4 26 5 26 6 27 7 30 8 30 9 30 10 31 11 31 12 32 13 33 14 34 15 35 16 47 17 48...

Страница 29: ...25 BG 1 dB dB...

Страница 31: ...27 BG 6 m a b c a b c d e f 30 mA a b c d e f...

Страница 32: ...28 BG g h a b c d e f g h a m 1 2 3 4...

Страница 33: ...29 BG 5 6 7 8 9 7 bar 10 2 50 m 55 C 30 m...

Страница 37: ...33 BG 13 ElektroG LIDL 25 2012 19...

Страница 38: ...34 BG 14 5 C...

Страница 39: ...35 BG 15 3 II 3 IAN 365039_2204...

Страница 53: ......

Страница 54: ......

Страница 55: ......