Page 2 / Bulletin 75-00 J

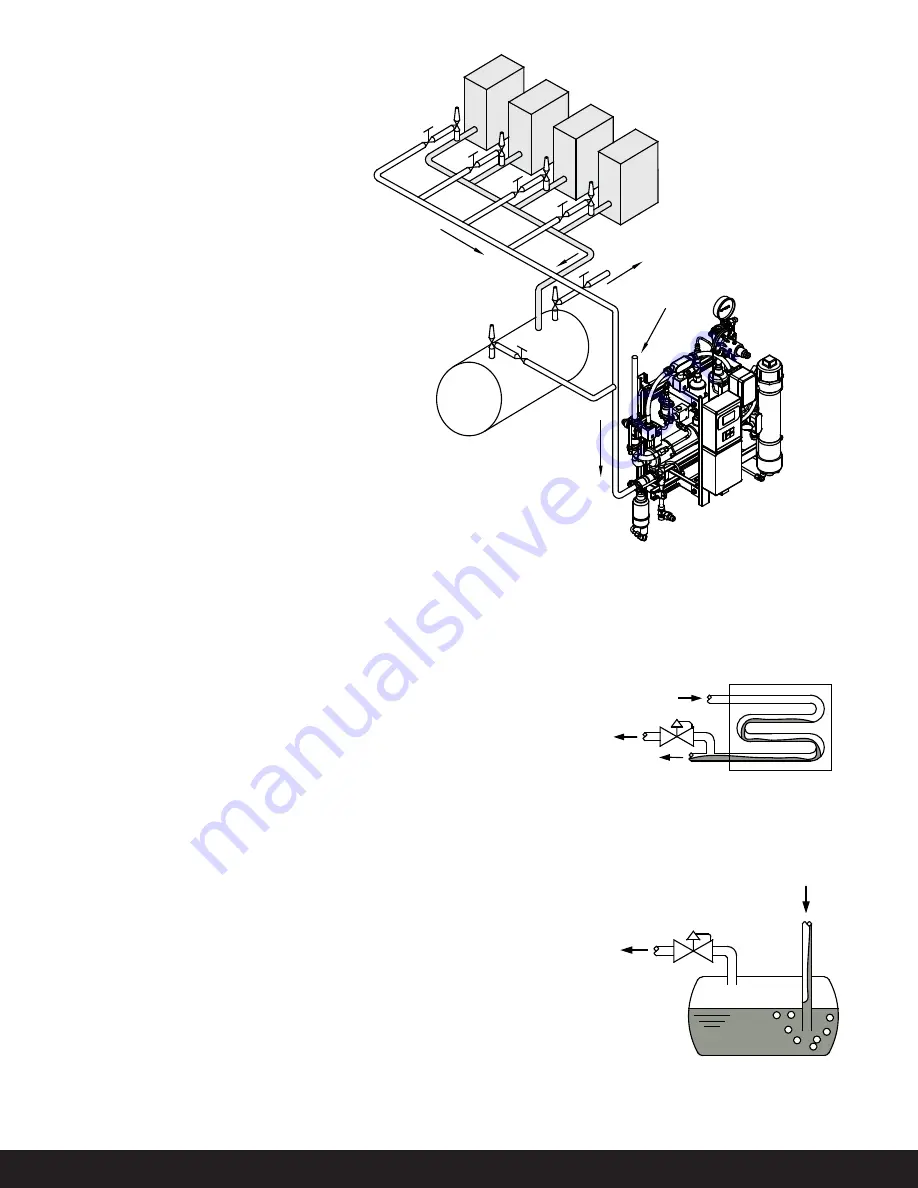

High

Pressure

Receiver

Evaporative

Condenser

Auto Purger

(Model V200)

Evaporator

Liquid Line

Liquid

Refrigerant

Line

Gas

Refrigerant

Line

Foul

Gas

Line

P

P

P

P

P

Purge Points

(P)

V200 Auto Purger Multiple Purge Points

High

Pressure

Gas

Refrigerant

Foul

Gas

Liquid

Refrigerant

P

High Pressure Receiver

Purge Point

Liquid

Refrigerant

Foul

Gas

P

Introduction

Non-condensables like air, hydrogen,

nitrogen, and hydrocarbon gases

reduce the overall capacity of

the refrigeration system. Higher

pressures, which in turn causes

longer compressor runtime, longer

condenser fan runtime, higher

compressor discharge temperatures,

increase compressor power costs,

increase wear and tear on equipment,

increase leaks, reduce system

effi

ciency, increase overall system

energy costs are all consequences of

non-condensables in the refrigeration

system.

In a refrigeration system non-

condensables can be introduced by:

• Inadequate system evacuation such

as servicing compressors, strainers,

valves, start-up, etc.

• Refrigerant additions

• Leaks from valve stem packings,

bonnet gasket, compressor shaft

seal, control transducers, etc.

• Separation of ammonia molecules

(hydrogen and nitrogen)

• Compressor oil breakdown

(hydrocarbon gases)

Th

e base V200 Rapid Auto Purger

removes the non-condensable gases

from four purge points. With the

addition of up to two slave units, 36

purge points possible. Th

is leads to

lower condensing pressure, runtime

of the compressors, and operating

costs.

Non-condensable indicators

are excessively high condensing

temperatures/pressures and

saturated temperature/pressure

deviations. One indicator is a higher

saturated condensing pressure/

temperature at the condenser for

the given outdoor air wet bulb

and heat rejection load. Another

indicator is the increasing diff erence

between the observed condensing

pressure and the saturation

pressure corresponding to the liquid

refrigerant temperature exiting the

condenser.

Purge Points

Th

e most common purge points

in a refrigeration system are at the

condenser drain, pilot receivers,

thermosyphon receivers, high

pressure receivers, liquid drain

header, equalizing lines, and low

velocity-high side areas.

Purge points should be located to

ensure no liquid refrigerant is drawn

by the purger. Th

e Auto Purger V200

has a liquid drainer at the foul gas

inlet to prevent any liquid refrigerant

from entering the shell side of the

heat exchanger.

Auto Purging

Th

e start of a purge cycle can

commence automatically, manually,

time based, central management,

and/or using the microprocessor. Th

e

Auto Purger V200 can only purge one

point at any given time.

In automatic mode each purge point

is sampled for a minimum of fi ve

minutes. If the purge conditions are

not met within the sample time limit,

the Auto Purger continues to the next

purge point. When a purge point

meets the purge conditions within

the sample time limit the Auto Purger

starts the purge cycle. Th

e purge

cycle shuts off when the non-purge

conditions are met.

Evaporative Condenser

Purge Point