38

Electronics for Closed Loop Control

Series PID00A-40X

Operation Manual

PID00A_10 5715-616 UK.indd CM 14.11.14

Parker Hannifin Corporation

Hydraulics Group

Improving system performance

Using the parameter P17 = I-gain

The integrator gain (abbreviated I) can be adjusted

to reduce or eliminate the error between the com-

manded and the measured velocity, when the com-

mand remains constant. Higher values of I-gain will

cause a better error reduction while the response

will be slower. This parameter is only effective if a

window (>0) is defined via P

Elimination of a slow oscillation with small am-

plitude in position

Due to friction and other application/system char-

acteristics, use of the I-gain sometimes causes a

slow, small amplitude during constant velocity. This

is a different problem from the vigorous oscillations

that occur when the P-gain is set too high. The

electronic provides a “Window” feature (sometimes

called “in-position-window”) to solve this problem.

Select the parameter P26. Small step adjustments

increasing the window size, sufficient to stop the

slow oscillations.

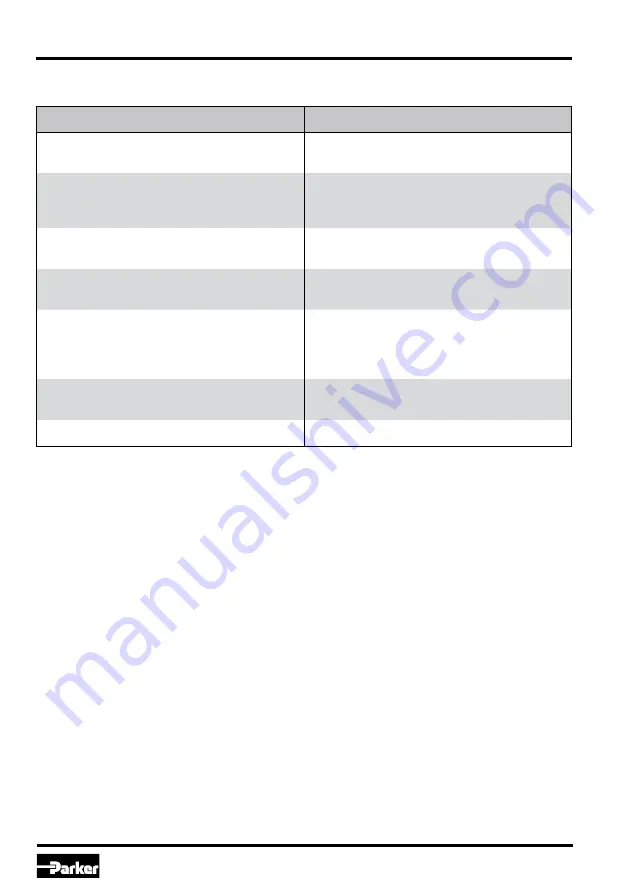

The table below gives information, which approaches may be embarked if typical problems with veloc-

ity control loops appear.

Problem

Solution

Variation error too large, when velocity

command remains constant

Use parameter

P17 = I-gain

(only effective for P26 >0)

Repeatable deviation by using a valve

with overlap/hysteresis

Use dead band compensation feature

P7 = MIN channel A

resp.

P8 = MIN channel B

Following error too large during

velocity profile execution

Use parameter

P13 = bypass gain

Slow, small amplitude oscillation

during constant velocity

Use integrator window

P26 = window I-gain

Disappointingly low P-gain

Check the frequency response of valve

and position transducer, the drive resonant

frequency and the feedback value processing

(s. items below)

Response too slow

Be sure

P16 = p-gain

is adjusted high

enough (s. also previous items)

In explainable problems

Check the setting of all parameters

Repeatable velocity errors due to valve dead

band or hysteresis

You can use the integrated dead band compensa-

tion coefficient to compensate for this. There are

separate adjustable parameters P7 and P8 for both

valve sides. This feature generates constant cor-

rection signals which will be active for the dedicat-

ed valve site if a signal occurs on the command

signal input. As a result this will cause the valve

to “Jump through“ the overlap region of the spool.

Increasing load stiffness

“Load stiffness” is the term for the resistance of

the servo loop to drive deflection by external forc-

es. Adjusting P16 to the highest practical value is

important.

Disappointing control loop function

The higher the value of the P-gain that can be used,

will result in better static and dynamic performance

of the system. You may not have any direct need for

fast response, but may still need a high value of P

Содержание PID00A-40 Series

Страница 44: ......