15

P1D

Cylinder

05.03

www.parker.com/euro_pneumatic

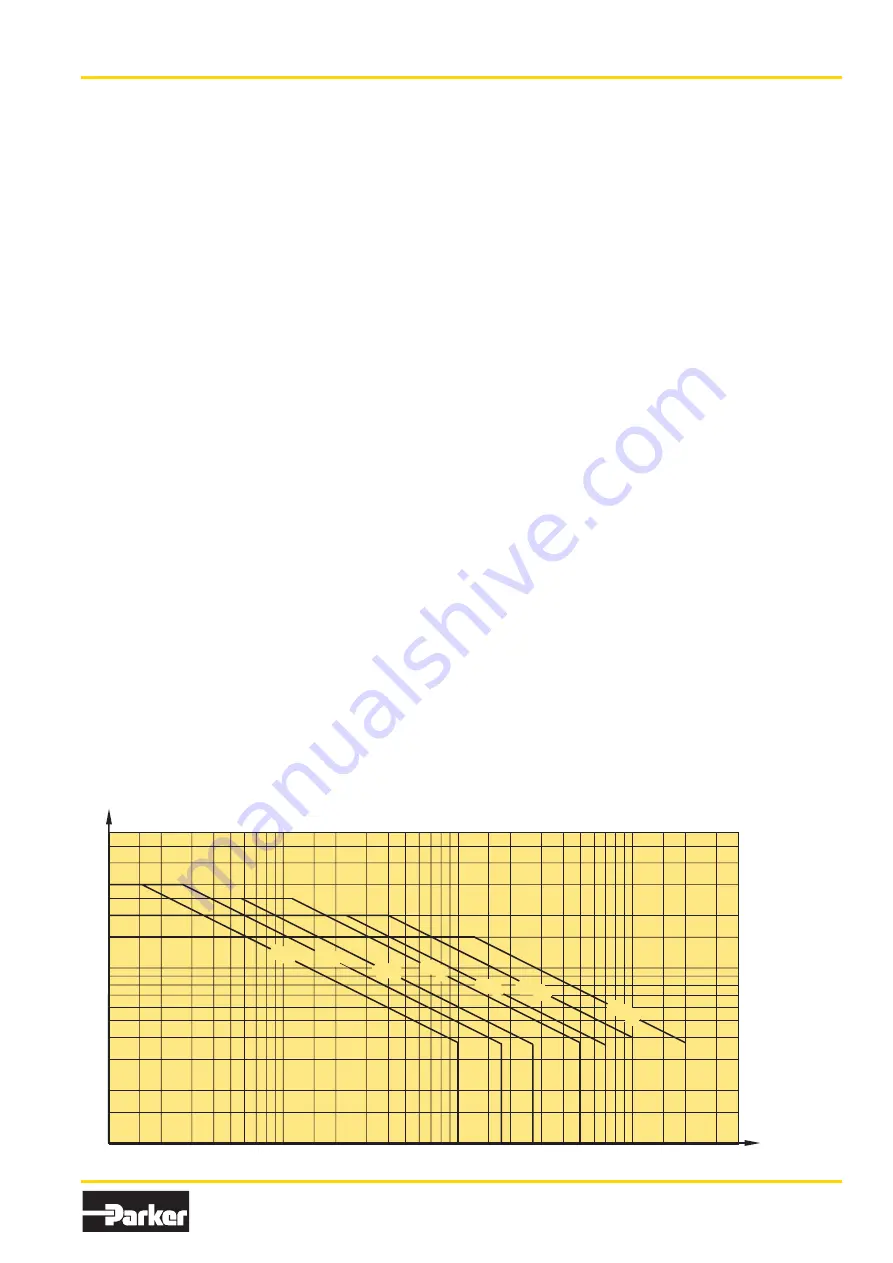

4,0

3,0

2,0

1,5

1,0

0,5

0,4

0,3

0,2

0,1

1

2

3 4 5

10

20

30 40 50

100

200 300

500

1000

2000

Ø32

Ø40

Ø50

Ø63

Ø80

Ø100

Ø125

Speed [m/s]

Mass [kg]

Material specification

Standard design

Body extrusion

Natural colour, anodised aluminium

End cover

Black anodised aluminium

End cover inserts

POM

End cover nuts/screws

Zinc plated steel 8.8

Piston rod nut

Zinc plated steel

Piston rod

Stainless steel, X 10 CrNiS 18 9

Scraper ring

PUR

Piston rod bearing

POM

Piston

POM

Piston bearing

POM

Magnetic ring

Plastic bound magnetic material

Piston bolt

Zinc plated steel

Piston seal

PUR

O-rings

Nitrile rubber, NBR

End-of-stroke washers

PUR

Cushioning seals

PUR

Cushioning screws

LCP

P1D Clean

Transparent moulding

Silicone

Transparent cover

ABS

Screws, sensor system

Stainless steel, A2

Upper seal and lower

seal, protective cover

Santopren

Sealing plugs

PA

Piston rod nut

Stainless steel, A2

P1D Flexible Porting

Connection hardware Ø32-63

POM

Elbow fittings Ø32-63

PA

Straight fittings on body extrusion Ø32-63

PA

Straight fittings in ports

Nickel plated brass

Seal, connection hardware

Nitrile rubber NBR

P1D Tie-Rod

Tie-rods

Stainless steel, X 10 CrNiS 18 9

Design variants

Low temperature design

Seals/scraper ring

Polyurethane PUR

Piston

Anodised aluminium

Piston/piston rod bearing UHMWPE plastic

High temperature design

Seals/scraper ring

Fluorocarbon rubber, FPM

Piston

Anodised aluminium

Piston/piston rod bearing Bronze filled PTFE

Low pressure hydraulics

Seals/scraper ring

Nitrile rubber, NBR

Piston

Anodised aluminium

Piston/piston rod bearing UHMWPE plastic

Cylinders for dry rod operation

Seals/scraper ring

FPM/HDPE

Option

Piston rod material

Hard-chromium plated steel, Fe 490-2 FN

Acid-proof steel, X 5 CrNiMo 17 13 3

Hard-chromium plated stainless steel,

X 10 CrNiS 18 9

Cushioning characteristics

The diagram below is used for dimensioning of cylinders related

to the cushioning capacity. The maximum cushioning capacity

shown in the diagram assumes the following:

• Low load, i.e. low pressure drop across the piston

• Equilibrium speed

• Correctly adjusted cushioning screw

• 6 bar at cylinder port

The load is the sum of internal and external friction, plus any

gravitational forces. At high relative load (pressure drop

exceeding 1 bar), we recommend that for any given speed, the

mass should be reduced by a factor of 2.5, or for a given mass,

the speed should be reduced by a factor of 1.5. This is in relation

to the maximum performance given in the diagram