K3.1.141e Manual NitroFlow HP_EN.doc

- 22 -

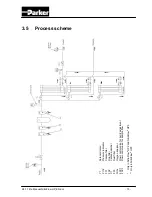

5.3

Compressed air supply

5.3.1 Ambient temperature of NitroFlow

®

HP

With increasing temperatures the pressurised air consumption will increase and

consequently the capacity will change. Make sure the temperature of the

compressed air is as low as reasonably possible.

5.3.2 Checklist for compressed air supply

The source of compressed air can be either a central compressed air system or a

stand-alone compressor dedicated to the nitrogen generator. The compressed air

entering the membrane gas separation section must be dry and non-condensing

(refer to §4.1).

Checklist when connecting to a central compressed air system

1.

Dew point of compressed air: < 5°C (< 41°F)

2.

System has sufficient capacity

3.

System can produce the required pressure (take pressure drop into

consideration)

Checklist when connecting to a dedicated stand-alone compressor

A compressor feeding a NitroFlow® HP should have the following characteristics:

1. Equipped with after-cooler cooling the compressed air to 10-15 °C (50-59°F)

above ambient temperature.

2. Equipped with incorporated or separate refrigerant dryer of sufficient capacity.

3. Equipped with oil separator (in case of oil lubricated compressor).

4. Equipped with water separator.

5. Suitable for continuous operation.

6. Equipped with modulating pressure control. If this option is not available a

backpressure vent valve can be installed as an alternative measure to

modulate the capacity.

7. Preferably the compressor is slightly over-dimensioned in case elevated

nitrogen delivery pressure is required.