EN

| User Manual

Maintenance and repair of the dryer

KA-MT 10-95/D3

39

Note:

The evaluation is based on a pressure-reduced partial fl ow that is fed into the

indicator tube at a pressure of 7 bar operating pressure.

For dryers with an operating pressure of less than 7 bar, please refer to the

respective table in the appendix (for 4, 5 or 6 bar operating pressure).

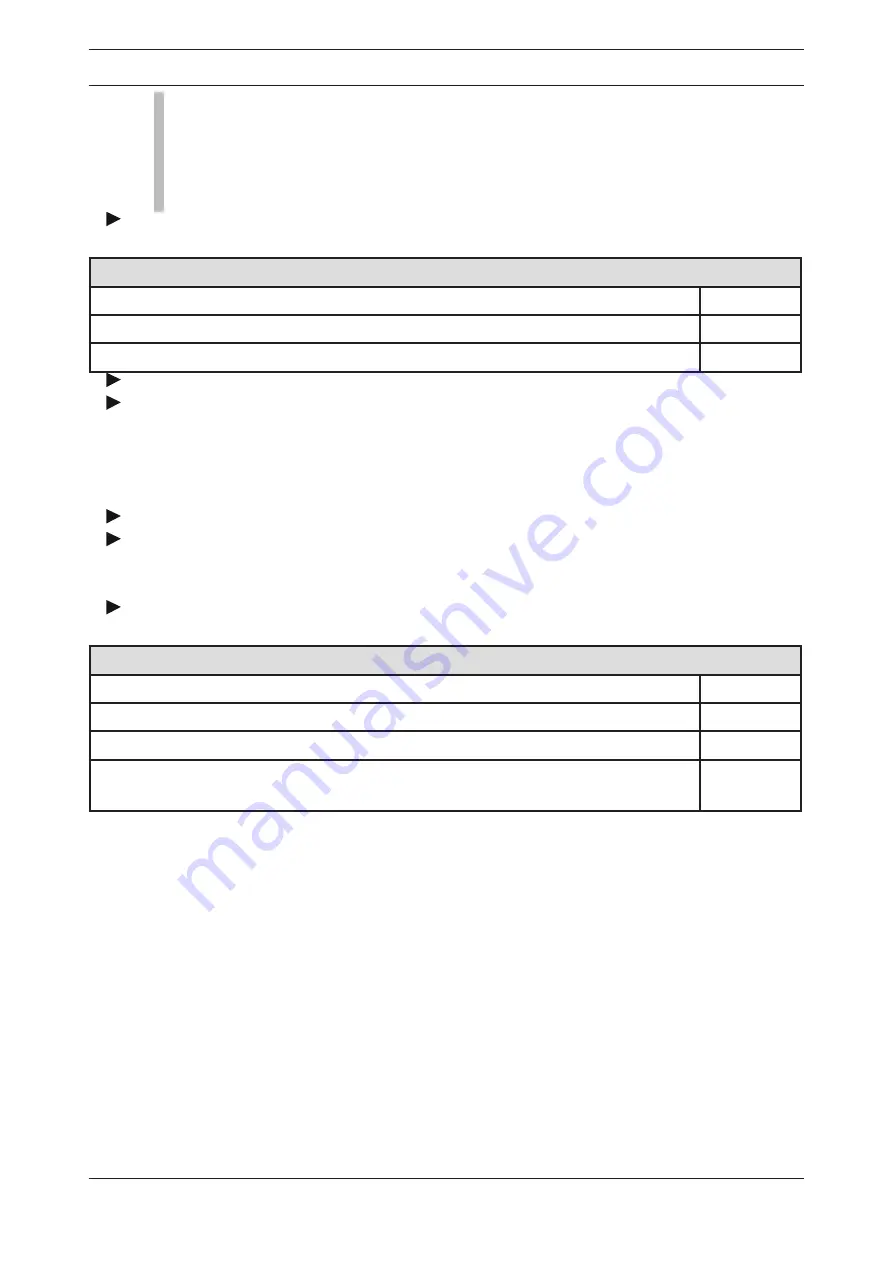

Determine the concentration in the above table, based on the duration of the measure-

ment and the number of scale segments with colour change.

Example

Duration of measurement in [h]

5.0

Number of scale segment with colour change

1.0

Residual oil concentration in [ppm]

2.25

Write down the residual oil concentration in ppm, parts per million] in the measuring log.

To determine the residual oil content in [mg/m3], multiply the above value by a factor 1.2.

Write down this value in the measuring log.

Determining capacity reduction of purifying agent

To establish the remaining capacity of the purifying agent, you must carry out measurements

of the same duration at fi xed intervals.

Choose a measuring interval (e.g. 4 weeks) and a duration of measurement (e.g. 4 hours).

Determine the maximum admissible residual oil concentration in [mg/m3] for your specifi c

application. Divide this value by 1.2 in order to obtain the maximum admissible residual oil

concentration in [ppm].

Refer to the table on page 38 and determine the corresponding number of scale seg-

ments with colour change.

Example

Maximum admissible residual oil concentration in [mg/m3]

3.4

Maximum admissible residual oil concentration in [ppm]

2.83

Duration of measurement in [h]

4.0

Maximum admissible number of scale segments with colour change

(across entire measuring sequence)

1.0

If there are no additional segments with colour change at the end of the measuring proce-

dure, the purifying agent is working at full capacity.

As its capacity is reduced over time, the number of scale segments with colour change in the

tube is increased.

If the established maximum admissible number of segments with colour change is reached,

the purifying agent must be replaced (see also page 46 ).

If all scale segments in the indicator tube show a colour change, the indicator tube is spent

and must be replaced as described below.