R35, 1/8" & 1/4" Miniature Regulators

IS-R35

Lightly grease with provided lubricant.

Inspect for nicks, scratches, and surface imperfections. If

present, reduced service life is probable and future

replacement should be planned.

Clean with lint-free cloth.

Service

Caution: Disconnect or shut off air supply and exhaust

the primary and secondary pressures before servicing

unit. Turning the Adjusting Knob counterclockwise does

not vent downstream pressure on non-relieving

regulators. Downstream pressure must be vented before

servicing regulator.

Caution: Grease packets are supplied with kits for

lubrication of seals. Use only mineral based grease or

oils. Do not use synthetic oils such as esters. Do not

use silicones.

Note: After servicing unit, turn on air supply and adjust regulator

to the desired downstream pressure. Check unit for leaks.

If leakage occurs, do not operate - conduct repairs and

retest.

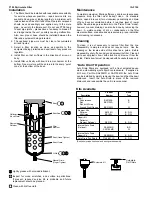

A. Servicing the Bonnet and Piston Assembly

1. Disengage the Adjusting Knob by pulling upward. Turn

Adjusting Knob counterclockwise until the compression is

released from the Pressure Control Spring.

2. Unscrew the threaded Bonnet Assembly. Next, disassemble,

clean, and carefully inspect parts for wear and / or damage.

Wipe parts, clean with soapy water or denatured alcohol. If

using compressed air to blow dry, be sure to wear appropriate

eye protection. If replacement is necessary, use parts from

service kits.

3. Lubricate Piston O-ring with grease (supplied with kits).

4. Install Piston and Pressure Control Spring into Body. Then

install Bonnet Assembly to Body and tighten to 4.5 to 5.6

Nm (40 to 50 in. lb.).

B. Servicing the Poppet Assembly

1. Exhaust system media pressure as previously described.

Then remove Bottom Plug by unscrewing it from Body. Next,

remove Bottom Plug Seal, Poppet Return Spring and Poppet

Assembly.

2. Next, disassemble, clean, and carefully inspect parts for wear

and / or damage. If replacement is necessary, use parts from

service kits.

3. Lubricate O-ring and sliding surfaces using grease supplied

with service kit.

4. Install parts as shown.

5. Lubricate Bottom Plug Seal and install it in o-ring groove in

body. Be sure Disc Stem fits into center area of Piston

Assembly before installing Bottom Plug. Install Return Spring,

then screw Bottom Plug into Body until it bottoms out in body.

Tighten to 3.5 to 5.1 Nm (35 to 45 in. lb.).

6. Turn on media source and adjust to desired secondary

pressure as described in the

Operation

section. Check

regulator for leakage. If leakage occurs,

DO NOT OPERATE

— conduct repairs again.

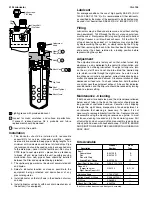

Service Kits / Parts Available

Description

R35, 1/8" & 1/4"

Regulator Repair Kit

(Relieving)

RKR30

Regulator Repair Kit

(Non-Relieving)

RKR30K

Spring Cage Kit (A Range)

CKR35A

Spring Cage Kit (B & C Range)

CKR35BC

Adjusting Knob

R35-0545P

Return Spring

SPR-445-1

Bottom Plug

R35-0021P

Bottom Plug Seal

GSK-504Z101

Accessories

Mounting Bracket / Nut

SA161X57

Panel Mount Nut

R05X51

Gauges

0 to 60 PSI (0 to 4 bar)

K4515N18060

0 to 160 PSI (0 to 11 bar)

K4515N18160

!

!

Adjusting Knob

Adjusting Screw Assembly

Bottom

Plug Seal

Bottom Plug - Torque:

3.5 to 5.1 Nm (35 to 45 in. lb.)

Inner Valve

(Poppet) Assembly

Control Spring

Spring, Return

Piston

Assembly

Piston

O-ring

Body

Spring Cage (Bonnet) Assembly -

Torque: 4.5 to 5.6 Nm (40 to 50 in. lb.)