F105 Particulate Filter

IS-F105

Installation

1. The filter should be installed with reasonable accessibility

for service whenever possible – repair service kits are

available. Keep pipe or tubing lengths to a minimum with

inside clean and free of dirt and chips. Pipe joint compound

should be used sparingly and applied only to the male

pipe – never into the female port. Do not use PTFE tape

to seal pipe joints – pieces have a tendency to break off

and lodge inside the unit, possibly causing malfunction.

Also, new pipe or hose should be installed between the

filter and equipment being protected.

2. The upstream pipe work must be clear of accumulated

dirt and liquids.

3. Select a filter location as close as possible to the

equipment being protected and upstream of any pressure

regulator.

4. Install filter so that air flows in the direction of arrow on

body.

5. Install filter vertically with bowl drain mechanism at the

bottom. Free moisture will thus drain into the sump “quiet

zone” at the bottom of the bowl.

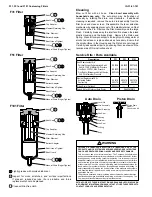

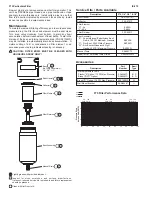

Bowl Seal

Body

Filter

Element

Bowl (Hand Tighten)

Bowl Guard

Deflector

(Vane Plate)

Element

Retainer

O-Ring

Manual Drain

(Finger Tighten)

Maintenance

To maintain maximum filtering efficiency, and to avoid excessive

pressure drop, the filter must be kept clean. On standard

filters, open drain cock (turn clockwise) periodically and drain

off any bowl accumulation before it reaches level of lower

baffle. Bowl drainage is automatic in the “Piston Drain” model,

however, manual draining can also be done by removing the

bowl. A visible coating of dirt or condensate on the filter

element surface, or an excessive pressure drop, is an indication

that cleaning is necessary.

Cleaning

To clean, it is not necessary to remove filter from the line.

Disassembly is simple and does not require tools. Use the

drawing on the reverse side of this sheet as a guide. Before

disassembly, shut off air supply and depressurize filter. Clean all

parts, except plastic bowl, with alcohol and blow out from the

inside. Plastic bowls must be cleaned with household soap only.

“Auto Drain” Operation

Auto Drain filters are equipped with a float actuated device

which automatically ejects liquid contaminants. If supplied in

Kit Form, Part No. SA602MD or SAF105MD, the Auto Drain

can be installed by simply removing the bowl and then the bowl

draincock. Insert the Auto Drain in place of the removed

draincock and reassemble the unit in reverse order.

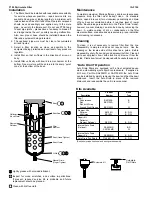

Kits Available

Product

Bowl

Description

Number

Type

Bowl*

Polyurethane

BKF105B

B

Zinc

BKF105D

D

Zinc with Wrap

Around Sight Gauge

BKF105W

W

Element Kits

5 Micron

EK100G

B, D, W

40 Micron

EK100J

B, D, W

Repair Kit

Deflector,

Element Retainer

RKF100

B, D, W

Internal Auto Drain

(Optional)

SA602MD

B, D

SAF105MD

W

Internal Auto Drain

Repair Kit

RK602MD

B, D, W

Auto Drain Dirt Shield

F700-0071P

B, D, W

*Bowl kits include bowl seal and bowl guard assembly.

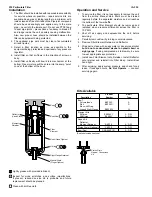

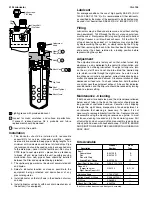

Lightly grease with provided lubricant.

Inspect for nicks, scratches, and surface imperfections.

If present, reduced service life is probable and future

replacement should be planned.

Clean with lint-free cloth.

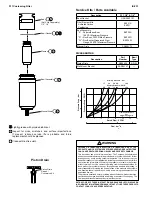

Autodrain Kit

Autodrain

Dirt Shield