8

VAC-SIF-05

Training & Maintenance Manual

CVX0260B

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Scheduled Maintenance

Filters –

Periodic maintenance of the vacuum filter is

necessary. The frequency of maintenance depends on the

environment and application. As the filter collects product from

the environment the maximum vacuum level potential and

response time may vary.

Silencer –

Periodic maintenance of the exhaust silencer may

be required. The frequency of maintenance depends on the

environment and condition of the air supply.

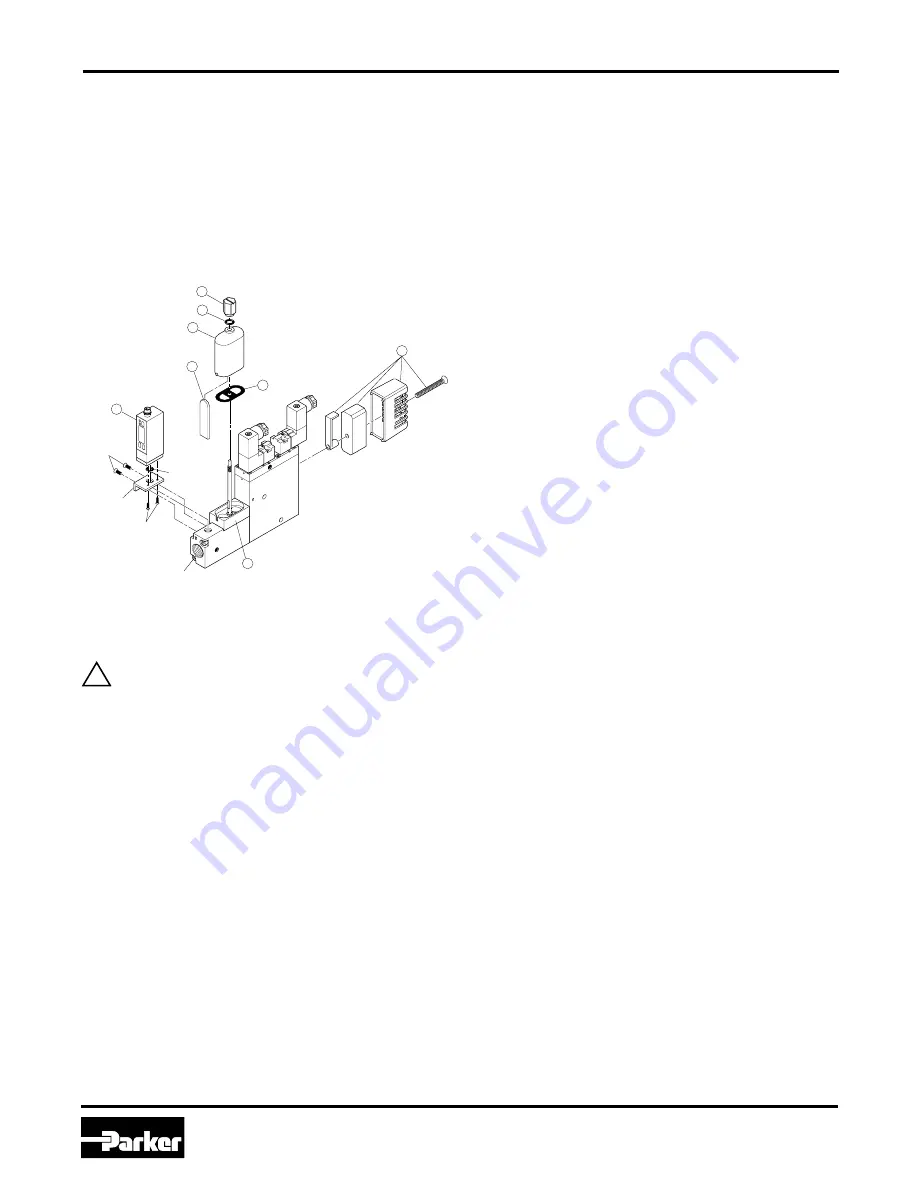

Sensor

Sensor

O-Ring

(P5)

Sensor

Mounting

Brkt.

Sensor

Mounting

Brkt. Screws

(M3x5)

Sensor

Mounting

Screws

(M2x6)

Vacuum

Port

Filter

Base

Filter

Element

Filter

Gasket

5

15

6

7

3

Filter

Cap

Filter O-ring

(M8x1.0)

4

Filter

Housing

2

1 Silencer

!

Cautions

• The CVX0260B does not require lubrication to function like

other pneumatic components.

• The CVX0260B functions efficiently at 70 PSI while in

operation. Regulate the inlet air pressure to 70 PSI during

operations.

• Inlet compressed air levels below 70 PSI will yield lower

vacuum levels and could effect the overall performance of

the system.

• Operating pressure must be maintained during an

Emergency Stop Condition for the Emergency Operating

System to maintain the current operating mode of the

vacuum generator.

• Filtrate the inlet air to protect the CVX0260B against

contaminating matter typically found in compressed air

systems ( i.e. rust, water, compressor oil, or other foreign

particles). A standard 40 micron filter is recommended.

• The CVX0260B inlet compressed air must be filtered,

regulated, and periodically maintenance to insure

maximum operating performance and warranty.

• The air economizing functions and check valves require

proper fittings and suction cups to prevent vacuum

leakage. The vacuum ports are 3/8" G or 3/8" NPT female

threads and require appropriate fittings to properly seal the

systems. For NPT fittings, use a dry seal or tape to seal

the fittings throughout the system.

• Primary vacuum filtration is always recommended between

the cups and the vacuum ports of the generator. Collection

of particles and other matter from the work piece will

reduce the maximum vacuum level of the unit over a period

of use. The frequency of the filter maintenance will vary

with each environment and application.

• Each CVX0260B incorporates a small filter housed on the

body to protect the internal components of the generator.

Additional maintenance of this filter will also vary with each

environment and application.

Trouble shooting

(1) Most systems are not closed. Vacuum Systems

can have leaks in the fittings, leaks through the

product, and by seal at the interface of the cup

and the product to be handled. Excessive leakage

may create a situation where the system vacuum

pressure cannot obtain part presence level, “P_3” or

Air Economizing Level “n_1”. Either the leaks in the

system must be eliminated or the sensor settings

will have to be changed to meet the parameters of

the vacuum system.

(2) The Nozzle / Diffuser relationship with the

compressed air is critical for peak performance. All

manufactures state an optimum inlet pressure for

the vacuum generators. Increasing compressed air

pressure above the optimum inlet pressure may

not increase the degree of vacuum and in some

cases may deter the creation of vacuum pressure.

Compressed air pressure less than optimum inlet

pressure will decrease the vacuum pressure and

flow performance of the vacuum generator.

(3) Exhaust flow paths typically have exhaust silencers.

These silencers can become clogged which creates

a backpressure on the Nozzle/Diffuser relationship.

This will decrease the maximum vacuum pressure

and flow performance of a generator.

(4) The CVX0260B unit has a built in Vacuum Filter.

These filters can become clogged which creates a

pressure drop in the system. This pressure drop will

reduce the available vacuum pressure at the cup.

It is the vacuum pressure that holds the part and cup

together. The vacuum generator creates a pressure

differential between the inside of the cup and the outside. It

is this differential pressure, the difference between the inside

pressure (vacuum pressure) and atmospheric pressure

that holds the cup and work piece together. If the generator

cannot create the system vacuum pressure, then it cannot

create enough differential pressure between the inside of the

cup and the work piece to hold the part. The part will either

drop or it will not be picked up.

Trouble shooting a vacuum system has a lot of the same

basic trouble shooting of compressed air systems. What is

the inlet pressure, use of the manual overrides to confirm

valves are “ok”, checking solenoid LED’s for electrical signals.

The main troubleshooting of vacuum systems is to determine

“WHY” the vacuum system pressure is not being created to

hold a part.

Maintenance & Troubleshooting