12

Parker Hannifin Corporation • Refrigerating Specialties Division

2445 South 25th Avenue • Broadview, IL 60155-3891

Telephone: (708) 681-6300 • Fax (708) 681-6306

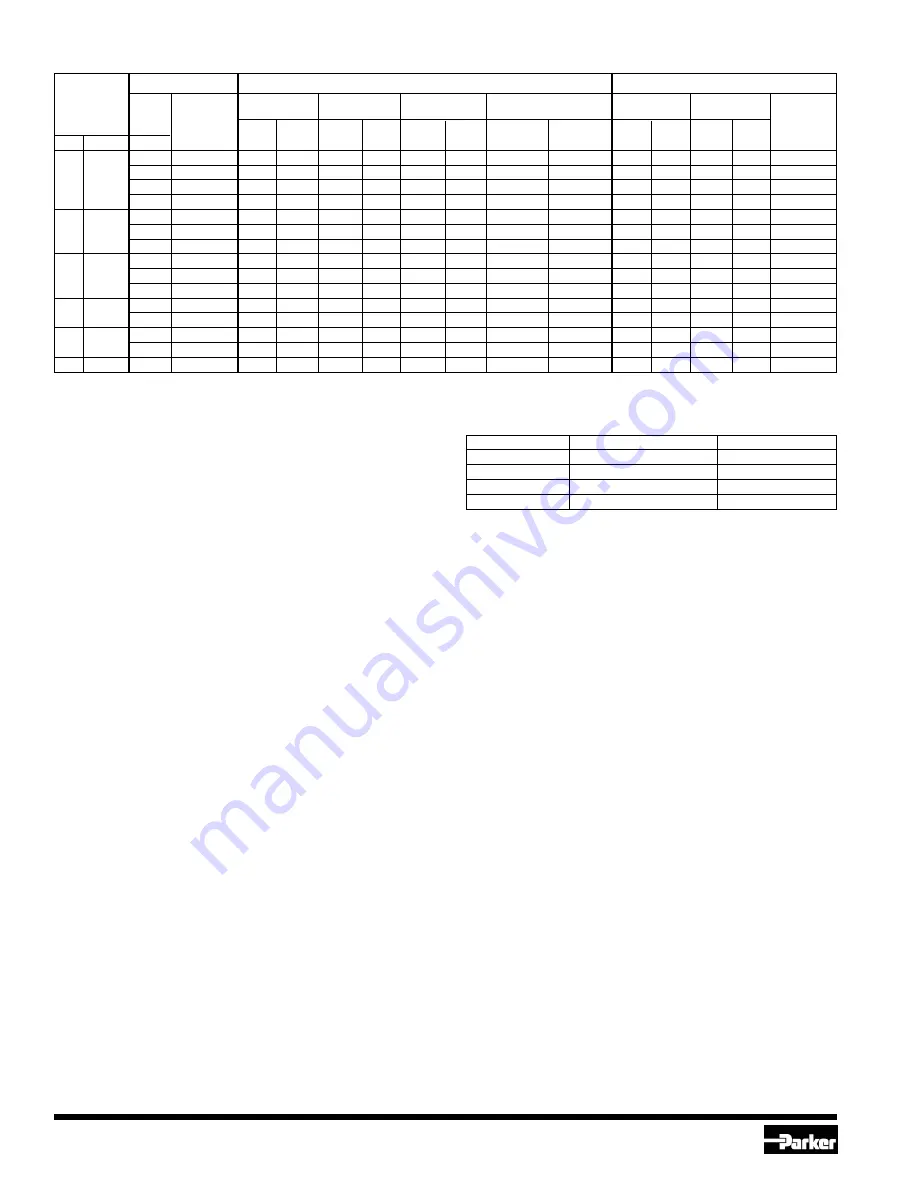

VALVE

➀

FPT FLANGES

WELDING FLANGES

➃

ODS FLANGES

SIZE

Nom

Nominal

Sock Weld

Weld Neck

Tubing

Fitting

Pipe

Pipe Size

Socket I.D.

Neck O.D.

Part No.

O.D.

I.D.

Part

Size

Part

➁

Socket

Weld

➂

No.

mm

Inches

Inches

No.

Inches NW No. Inches

mm

Inches

mm

Weld

Neck

Inches

mm

Inches

mm

1/2

00-1179-00

1/2

15

0.860

21.84

—

—

00-1180-00

N.A.

7/8

22.22

0.877

22.27

30-0108-13

20

3/4

3/4

00-1181-00

3/4

20

1.070

27.81

1.050

26.67

00-1114-00

00-1182-00

1-1/8

28.57

1.130

28.70

30-0108-10

and

and

1

00-1031-00

1

25

1.365

34.67

1.315

33.40

00-1033-00

00-1098-00

1-3/8

34.92

1.380

35.05

30-0108-11

25

1

1-1/4

00-1117-00

1-1/4

32

1.705

43.31

1.660

42.16

00-1118-00

00-1155-00

1-5/8

41.27

1.631

41.43

30-0108-12

1-1/4

00-1094-00

1-1/4

32

1.705

43.31

1.660

42.16

00-1035-00

00-1100-00

1-3/8

34.92

1.380

35.05

30-0109-10

32

1-1/4

1-1/2

00-1120-00

1-1/2

40

1.930

49.02

1.900

48.26

00-1121-00

00-1161-00

1-5/8

41.27

1.631

41.43

30-0109-11

2-1/8

53.97

2.131

54.13

30-0109-12

40

1-5/8

1-1/2

00-1038-00

1-1/2

40

1.930

49.02

1.900

48.26

00-1040-00

00-1103-00

1-5/8

41.27

1.631

41.43

30-0110-10

and

and

2

00-1042-00

2

50

2.445

62.10

2.375

60.33

00-1044-00

00-1074-00

2-1/8

53.97

2.131

54.13

30-0110-11

50

2

2-5/8

66.67

2.631

66.83

30-0110-12

65

2-1/2

2-1/2

00-1047-00

2-1/2

65

2.945

—

2.875

73.03

00-1070-00

00-1049-00

2-5/8

66.67

2.631

66.83

30-0111-10

3-1/8

79.37

3.131

79.53

30-0111-11

75

3

3

00-1053-00

3

80

3.575

90.81

3.500

88.90

00-1071-00

00-1055-00

3-1/8

79.37

3.131

79.53

30-0112-10

3-5/8

92.07

3.631

92.23

30-0112-11

100

4

4

00-1057-00

4

100

4.575

116.20

4.500

114.30 00-1104-00

00-1059-00

4-1/8

104.77

4.132

104.95 30-0113-10

➀

FPT: Internal NPT (USA Standard Taper Pipe Thread).

➁

NW: Metric equivalent nominal size for steel tubing.

➂

Metric copper tubing used for refrigeration.

➃

ODS connections to fit copper tubing of given outside

d

iameter. (Not for use with ammonia)

Definitions:

ODS - Outside Diameter Sweat

I.D. - Inside Diameter

O.D. - Outside Diameter

N.A. - Not Available

Flange Bolt Torque Requirements

Bolt Diameter

Valve Port Size

Torque

11 mm (7/16")

13mm (1/2 ")

3.9 mkg (28 ft lb)

16m m (5/8")

20-50mm (3/4 "- 2")

11.8 mkg (85 ft lb)

19m m (3/4")

65-75mm (2-1/2 "- 3")

14.5 mkg (105 ft lb)

22mm (7/8")

100mm (4")

22.1 mkg (150 ft lb)

FLANGE TABLE

SAFE OPERATION

(See Bulletin RSB for further information.)

The personnel doing any work on a refrigeration system must be

qualified and completely familiar with the system, or all other

precautions will be meaningless.

Where cold liquid lines are used, it is important that certain

precautions are taken to avoid damage due to liquid expansion.

Temperature increase in a section full of solid liquid can cause high

pressures due to the expanding liquid and possibly rupture a gasket,

pipe or valve. All hand valves in such locations should be marked,

warning against accidental closing, and must not be closed until the

liquid is removed. Check valves must never be installed upstream of

solenoid valves or regulators with electric shut-off, nor should hand

valves upstream of solenoid valves or downstream of check valves

be closed until the liquid has been removed. It is advisable to install

relief devices in any section where liquid expansion could take place.

For the protection of personnel and products, all refrigerant should

be removed from the section to be worked on before a valve, strainer

or other device is opened. Special care should be taken when

pumping out a strainer, liquid may be trapped in the strainer and

considerable time may be required to remove it.

Strainer inspection is of utmost importance, especially the first few

hours, days or weeks after the start-up. The strainers should be

opened and any dirt removed. Strainer inspection and cleaning should

be continued until dirt accumulation ceases. Later, any time a valve

is opened for service or maintenance, its companion strainer should

also be inspected and cleaned.

WARRANTY

All Refrigerating Specialties products are warranted against defects in

workmanship and materials for a period of one year from date of shipment

from originating factory. This warranty is in force only when products are

properly installed, maintained, and operated in use and service as

specifically stated in Refrigerating Specialties Catalogs or Bulletins for

normal refrigeration applications, unless otherwise approved in writing by

Refrigerating Specialties Division. Defective products, or parts thereof

returned to the factory with transportation charges prepaid and found to

be defective by factory inspection will be replaced or repaired at

Refrigerating Specialties option, free of charge, F.O.B. factory. Warranty

does not cover products which have been altered or repaired in the field;

damaged in transit, accidents, misuse, or abuse. Products disabled by

dirt or other foreign substances will not be considered defective.

The express warranty above constitutes the only warranty of Refrigerating

Specialties products, and is in lieu of all other warranties, expressed or

implied, written or oral, including any warranty of merchantability or

warranty of fitness for a particular purpose and in no event is

Refrigerating Specialties responsible for any consequential damages

of any nature whatsoever. No employee, agent, dealer or other person

is authorized to give any warranties on behalf of Refrigerating Specialties

nor to assume for Refrigerating Specialties any other liability in connection

with any of its products.

FACTORY REPAIR AND REBUILDING

For the convenience of our customers, we have a standard factory repair

and re-building service. Repairable returned Regulators are disassembled,

cleaned, sandblasted, worn parts replaced, reassembled, and re-painted.

For quickest service, it is advisable that this be done during the off peak

season.