Bulletin MSG30-3245-INST/UK

Installation Manual

5

Parker Hannifin

Pump & Motor Division Europe

Chemnitz, Germany

Axial Piston Pump

Series PV, series 44 and higher

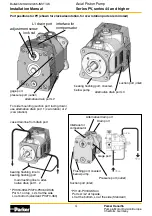

Flushing port

The PV pumps of design series 44+ are equipped

with three drain ports*. In addition pumps with seal

option W and P, all pumps PV140 - PV360 and pumps

with X-modification X5830 (bearing flushing port)

are equipped with a flushing port for front bearing

and shaft seal. The flushing flow can - depending on

the actual working conditions - be used to keep the

pump case filled, to warm up the pump (during cold

temperature operation) or for better heat dissipation

e. g. for operation with HFC fluids (water glycole) to

keep the case fluid temperature in the allowed range.

Permanent dead head operation ( >15 min) either for

pumps of frame size 3 and larger (PV063 and higher)

or at high input speeds above 1,800 rpm requires

flushing of the pump case.

Flushing should be taken from the filter/cooling

circuit (e. g. pre-loaded return line). Recommended

flushing flows see following table.

PV016 - PV028

4 - 6 l/min

PV032 - PV046, PV076

5 - 8 l/min

PV063 - PV092

7 - 10 l/min

PV140 - PV180

9 - 12 l/min

PV270 - PV360

13 - 17 l/min

(flushing flow for front bearing: 10 - 15% of the total

flushing flow)

Drive input

For direct drive use elastic coupling free of axial

and radial reaction forces. Please follow strictly the

instructions of the coupling supplier regarding axial

clearance, axial displacement and angular toler-

ances. Couplings never shall be mounted using a

hammer. Threads in the shaft end allow smooth

mounting of the coupling.

The drive shaft should only carry true torque.

Contact Parker for allowable side loads or axial forces.

PV pumps are normally for one direction of rotation

only. Therefore check rotation of drive motor prior to

installation.

Electrical interface

Check voltage, current, phase and connection prop-

erties. Verify direction of motor rotation.

Fluid reservoir

The reservoir needs to meet all system requirements

concerning design, size, location and porting. Beside

beeing reservoir for the hydraulic fluid, the tank also

supports heat dissipation, air removal, water removal

and contamination sedimentation. Often the reservoir

also is the fundament for the motor pump unit. In this

case the separation of pump and remaining struc-

ture by elastic means is mandatory to avoid noise

and vibration being induced into the frame work.

The reservoir needs to be carefully sealed against

ingression of contamination and water. A level indica-

tor and thermometer should be placed in an easily

accessible location.

Fluid content (general rule): stationary systems 3

to 4 times pump nominal flow, 1 times or even smaller

in mobile systems.

Filling of the system

Use only high quality mineral oil based fluids, like

HLP oils according to DIN 51524 part 2. For other

fluids (HFC, HFD, bio degradable or synthetic fluids)

please contact Parker and review the Hydraulic Fluids

Information in Catalogue 2500/UK.

Operation viscosity should be 16 to 100 mm²/s, op-

timum viscosity range is in the 20 to 40 mm²/s, max.

viscosity for short time up to 320 mm²/s.

Because of the possibly uncompatible ingredients

fluids should not be mixed (separation of fluid, reduc-

tion or loss of fluid properties).

Pay highest attention on cleanliness!

Fill system only via a filtration device. Use filtration

unit, when basic contamination of the refill fluid ex-

ceeds class 10 according NAS 1638 (contamination

level 21/19/16 according to ISO 4406). Hydraulic

fluid supplied in barrels typically exceeds these con-

tamination levels.

Filtration

Filtration is the most important factor to the opera-

tional life of the hydraulic system. Statistical analy-

ses indicate, that contamination is by far the most

important reason for system or component failure.

Use return line, pressure and/or bypass filtration.

Bypass filtration usually is most efficient. For general

purpose hydraulic systems with limited requirements

for operational life contamination level 19/15 accord-

ing to ISO 4406 should be desired; corresponding fil-

ter rating: x = 25

µ

m ( b

25

≥

75 ) according to ISO 4572.

Cleanliness level for systems with higher re-quire-

ments for operational life and functional safety should

be 18/16/13 according to ISO 4406; corresponding

filter rating x = 10

µ

m ( b

10

≥

75 ) according to ISO 4572.

Use filter with indicator or electrical signal when

capacity limit is approached.

Suction filter should be avoided. Suction condi-

tions will be affected. Filter can be blocked and cause

cavitation and severe pump damage. When used, a

vacuum sensor with shut off function is mandatory.

Properly dimensioned breather rating

≤

10

µ

m

should be used. Observe min. and max. fluid level;

consider exchange volume with cylinders in the

system.

Filling of pump case

Pump case must be filled via the drain port, to ensure

lubrication, sealing and smooth start up.