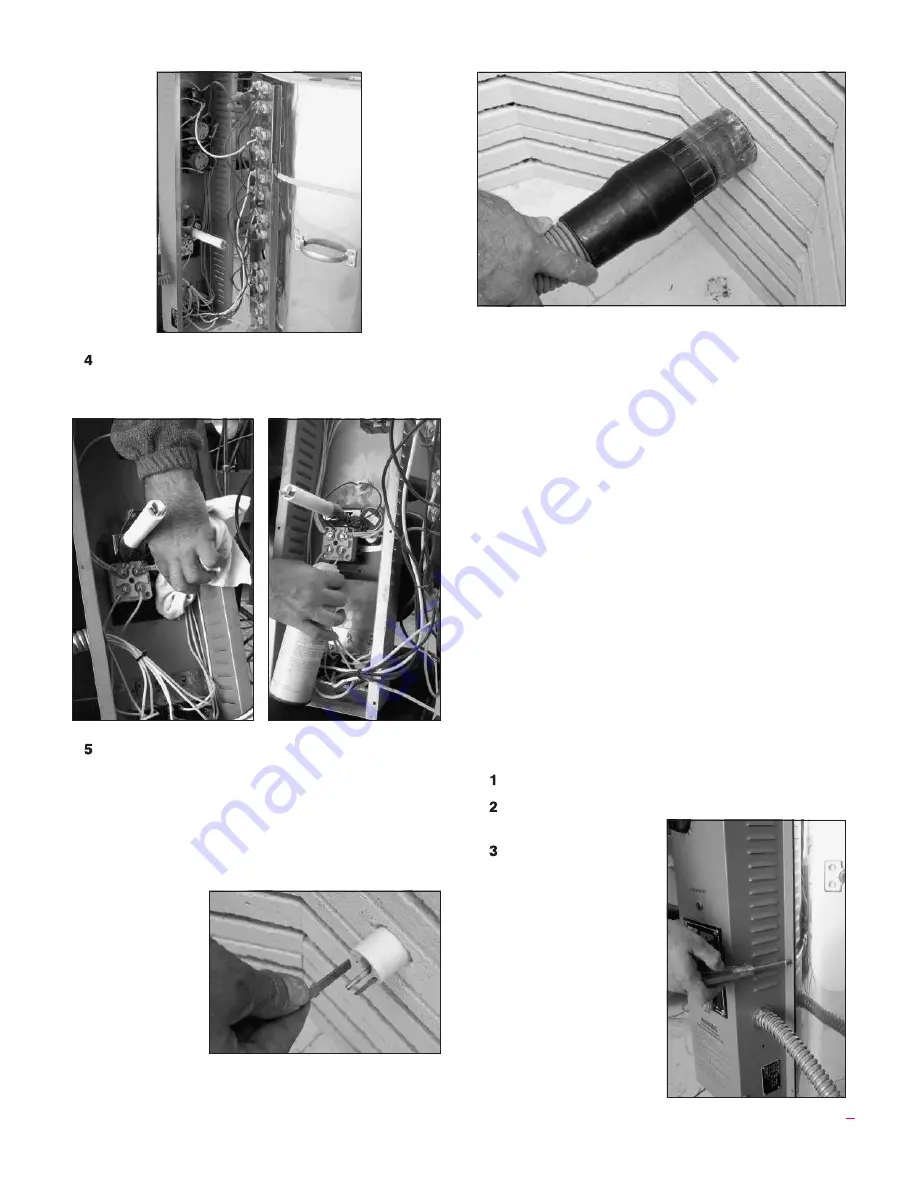

Leaving the wires attached to the Kiln Sitter, clean

the backside of the Kiln Sitter. Canned air is help-

ful. (But do not blow air into the Kiln Sitter tube.)

Reinstall the switch box. Arrange the wires so they

do not interfere with the locking slide that trips

when the weight drops. (You can see how the lock-

ing slide works by lifting the weight, pressing the

plunger, and then dropping the weight.) Also, ar-

range the wires inside the switch box so that wires

do not touch the element connectors or the kiln

case.

Clean the Kiln

Sitter Tube

Each time you

vacuum the kiln,

also vacuum the

Kiln Sitter tube as-

sembly. First, re-

move the cone

supports from the

Kiln Sitter tube.

Then place a vac-

uum hose directly over the tube. This removes debris and

rust from around the pivot point. Do not blow com-

pressed air into the tube.

Debris from exploding ware inside the kiln sometimes

lodges in the Kiln Sitter refractory tube. These fragments

can interfere with the travel of the actuating rod, resulting

in an overfire. After you have removed exploded clay frag-

ments from the firing chamber, always check the refrac-

tory tube for debris. It may not be readily apparent that

fragments are inside the tube. Check the travel of the ac-

tuating rod. It should be free to move up and down

without binding.

Note:

Probe the inside of the Kiln Sitter tube with

a clean artist’s brush. Keep the brush near the

kiln for checking the tube.

Replacing the Porcelain

Tube Assembly

Replace the porcelain tube assembly when the move-

ment of the sensing rod becomes sluggish or when the

sensing rod is bent. Be sure the replacement tube assem-

bly is the correct length for you kiln.

Disconnect the power to the kiln.

Make sure there is no cone or firing gauge in the

Kiln Sitter.

Remove and save the

screws at the side of

the switch box that

hold it to the kiln and

remove the box, care-

fully pulling straight

out to avoid damaging

the Kiln Sitter tube.

You may need to prop

the box on a chair or

other object as you lean

the box against the

kiln. Leave the wires

attached to the Kiln

Sitter.

19

Place the vacuum hose directly over the Kiln Sitter tube.

Remove the cone supports before vacuum-

ing the Kiln Sitter tube.