PAT1M / PAT1.5M OPERATION MANUAL

PAT1M/PAT1.5M: PA22222A01_03

Page: 23 of 36

Dec., 2007

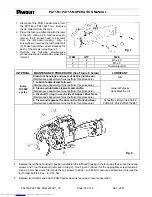

Problem 4 - Jaw sensor error

Jaw sensor error

Help

Buzzer

Continue

POSSIBLE CAUSE:

A build up of debris in the tool gears caused by not emptying the tip collector often enough.

CORRECTIVE ACTION:

Press the

"Buzzer"

button to turn the buzzer signal "off". Remove the cable tie and any

obstruction from the jaw and exit areas of the tool, and empty the tip collector. Press the continue button and resume

operation.

PREVENTION:

Always empty the tip collector before it is full (no more than 180 cycles). Keeping the tip collector

clear will allow the cable ties an area to exit the tool. The tool should also be cleaned periodically by your

maintenance department.

Problem 5 - System error #X

System error #X

Help

Mem off

Continue

POSSIBLE CAUSE:

There are 5 different functional messages that may appear. System error #1, #2, #3, #4, and

#5 will appear if an internal electronic component malfunctions.

CORRECTIVE ACTION:

For System errors #1 and #2, write down the system error number and notify your

maintenance department immediately. For System errors #3, #4, and #5, toggle the power switch (turn the power

“off” and then back “on” again) to reset the system. If the message disappears, resume operation. If the message

still appears, press the

"Continue"

button and resume operation. If the System error message does not disappear,

do not resume operation. Write down the system error number and notify your maintenance department immediately.

PREVENTION:

None.

STATUS MESSAGES

Status messages are displayed as the dispenser performs self-diagnoses. No action is required on the part of the

operator other than notifying the maintenance department of the status message.

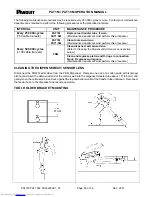

STATUS 1 - Calibrate line pressure sensor

Panduit

Calibrate line pressure sensor

STATUS 2 - Calibrate back pressure sensor

Panduit

Calibrate back pressure sensor

electronic components distributor