26/36

USER AND MAINTENANCE MANUAL I ENG_OMM_CD100_P07 I 2022-10-19

@Pandrol 2022

8. Operation CD100

CD100 is a walk-behind machine to be pushed by hand.

To operate the Power Unit you always need to have a working tool connected. The working tool

is also the parking support on the rail. When not operating the Power Unit and its working tools

they are to be stored into their suitable boxes.

Ì

WARNING! When the equipment is being used the operator must use protecting

clothes i.e. long trousers, boots, gloves, ear defenders and goggles or a

protective visor.

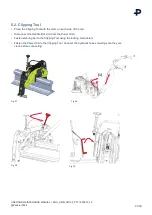

8.1. Clipping – Connect Rail To Sleeper

1. Setup the machine on the rail with the arms placed on either side of the rail. Connect the

engine power unit according to assembly instructions. Connect the hydraulic hoses (make

sure that they are clean prior to connection). Ensure that you are using correct claws and

arms. Switch the ON/OFF button on the motor unit to ON and pull the recoil starter to start

the engine.

2. Push the machine forward until the claws are correctly placed along the clips. Make sure

that the claws are placed in a proper position relative to the clip.

3. Accelerate the tool using the accelerator on the right handle. The arms will contract and

insert the clips.

4. When the clips fastened: activate the left handle for reversed movement of the arms until

the arms are in their origin position. Lift the machine slightly and repeat according to 2-4.

Fig 41.

Accelerator

Change of direction control

Fig 42.

Above specifications may be changed without notice according to Pandrol AB´s requirements.