5.1.11. DEFEATING THE AUTO TRACKING

To defeat the Auto Tracking Function, place the instrument in

the STOP mode and place a jumper between TP6003 and

TP6009 on the TV/VCR Main C.B.A. The tracking will be

placed in the neutral position.

5.1.12. HOW TO SET TRACKING TO THE

NEUTRAL POSITION

Ejecting the cassette tape and then reinserting it will reset the

tracking to the Neutral position.

5.1.13. BLACK SCREWS ON THE

CHASSIS

Black Screws are used on the Mechanism Chassis to identify

screws that require adjustment.

5.1.14. HOW TO RESET ALL

COMBINATION VCR MEMORY

FUNCTIONS

To reset (clear) the select language, channel auto set and set

clock functions to their initial power on condition (power on, no

cassette inserted), hold down the PLAY and FF buttons on the

unit together for more than 5 seconds.

Power will shut off.

5.1.15. HOW TO CONFIRM AUTO CLOCK

SET FEATURE

1. Connect an RF cable from the output of one unit to the input

of the test unit.

2. Select corresponding RF channels.

3. Playback a recording of P.B.S. channel including clock set

data and confirm this feature.

5.1.16. VARIABLE VOLTAGE ISOLATION

TRANSFORMER

An Isolation Transformer should always be used during the

servicing of Combination VCR whose chassis is not isolated

from the AC power line. Use a transformer of adequate power

rating as this protects the technician from accidents resulting in

personal injury from electrical shocks. It will also protect

Combination VCR from being damaged by accidental shorting

that may occur during servicing.

Also, when troubleshooting the above type of Power Supply

Circuit, a variable isolation transformer is required in order to

increase the input voltage slowly.

5.1.17. SPECIAL NOTE

All integrated circuits and many other semiconductor devices

are electrostatically sensitive and therefore require the special

handling techniques described under the

"ELECTROSTATICALLY SENSITIVE (ES) DEVICES" section

of this service manual.

5.1.18. REPLACEMENT PROCEDURE FOR

LEADLESS (CHIP) COMPONENTS

The

following

procedures

are

recommended

for

the

replacement of the leadless components used in this unit.

1. Preparation for replacement

a. Soldering Iron

Use a pencil-type soldering iron that uses less than 30

watts.

b. Solder

Eutectic Solder (Tin 63 %, Lead 37 %) is recommended.

c.

Soldering time

Do not apply heat for more than 4 seconds.

d. Preheating

Leadless

capacitor

must

be

preheated

before

installation. -(266 °F ~ 302 °F)

(130 °C ~150 °C) for about two minutes.

Note:

a. Leadless

components

must

not

be

reused

after

removal.

b. Excessive mechanical

stress and

rubbing of the

component electrode must be avoided.

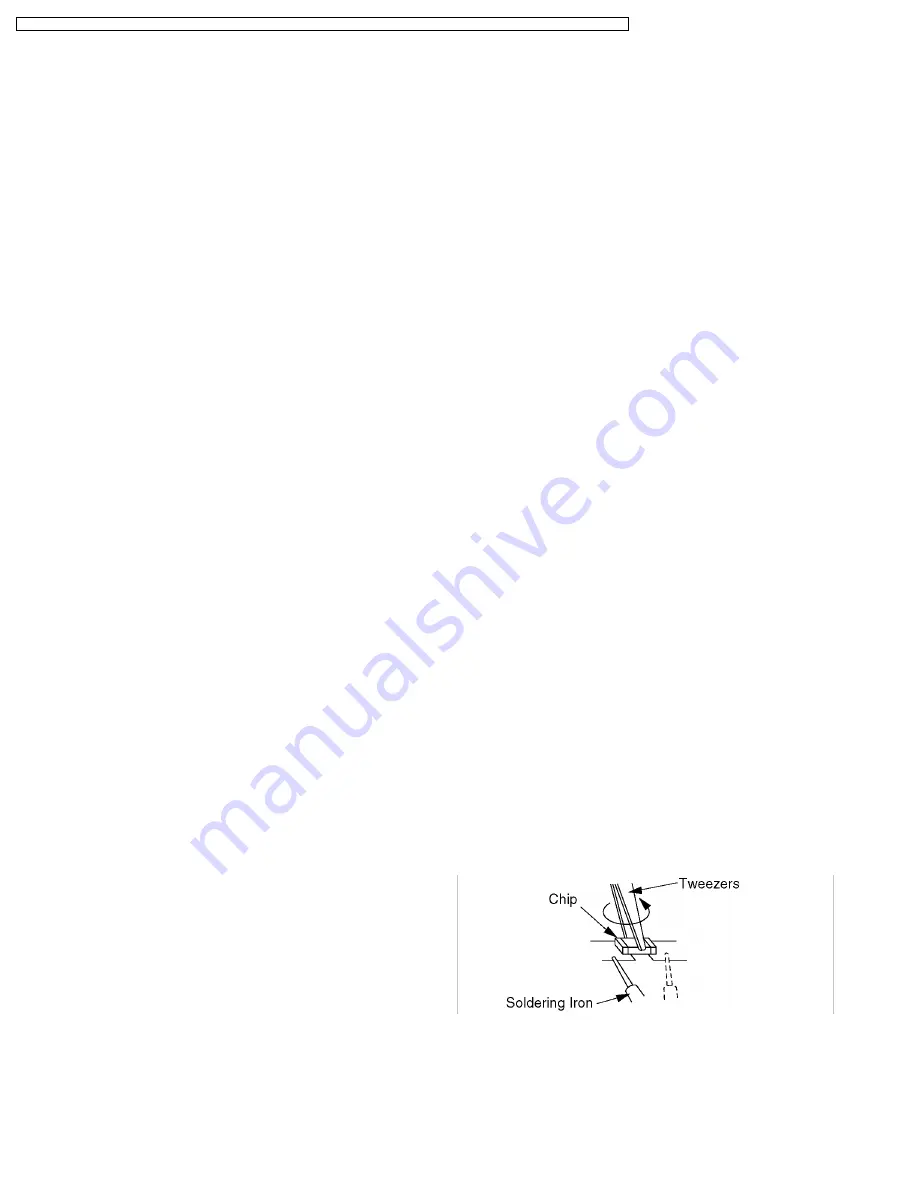

2. Removing the leadless component

Grasp the leadless component body with tweezers and

alternately apply heat to both electrodes. When the solder

on

both

electrodes

is melted, remove

the leadless

component with a twisting motion.

Note:

a. Do not attempt to lift the component off the board until

the component is completely disconnected from the

board by a twisting action.

b. Be careful not to break the copper foil on the printed

circuit board.

Fig. 9-1

3. Installing the leadless component

a. Presolder the contact points on the circuit board.

20

PVQ-1310 / PV-C1320 / PV-C1330W / VV-1300 / VV-1310W / PV-C1340 / PV-C1350W / PV-C2010 / PV-C2020 / PV-C2030W / VV-2000 / PV-C2060

Содержание QUASAR PV-C1320

Страница 59: ...59 PVQ 1310 PV C1320 PV C1330W VV 1300 VV 1310W PV C1340 PV C1350W PV C2010 PV C2020 PV C2030W VV 2000 PV C2060...

Страница 60: ...60 PVQ 1310 PV C1320 PV C1330W VV 1300 VV 1310W PV C1340 PV C1350W PV C2010 PV C2020 PV C2030W VV 2000 PV C2060...

Страница 106: ...106 PVQ 1310 PV C1320 PV C1330W VV 1300 VV 1310W PV C1340 PV C1350W PV C2010 PV C2020 PV C2030W VV 2000 PV C2060...