9

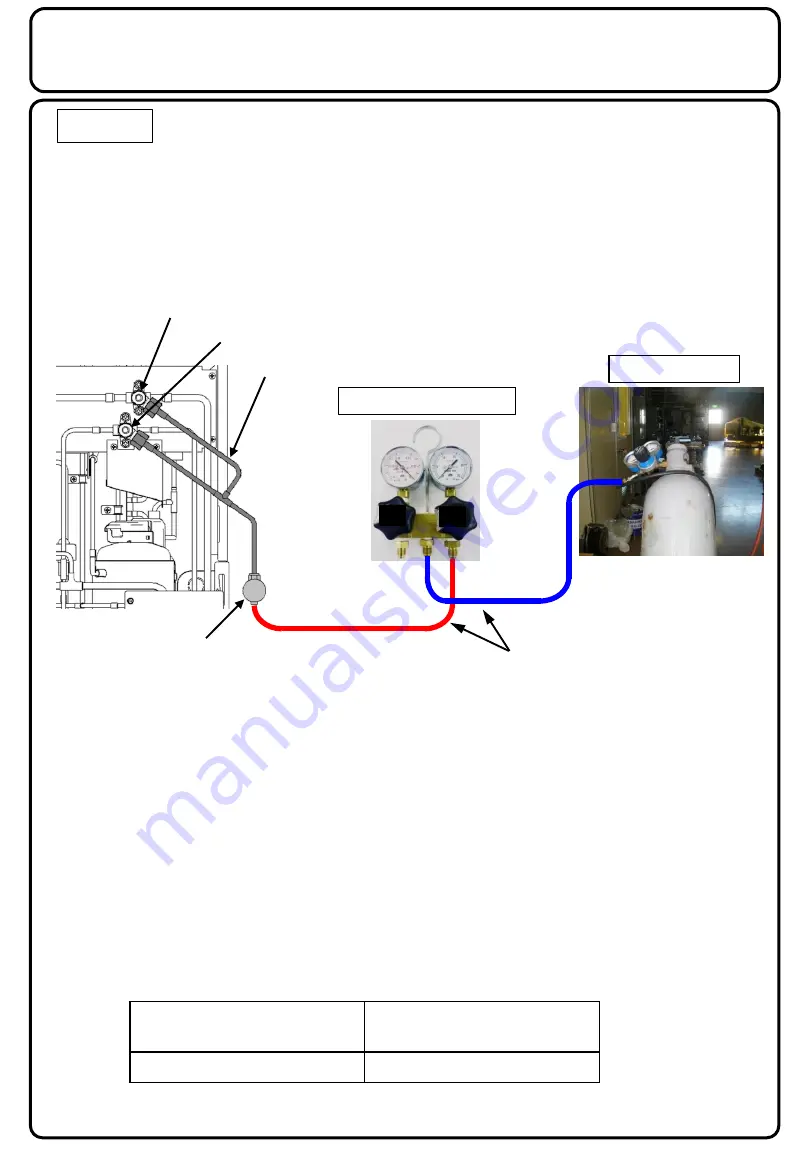

Airtight Test Procedure

(Execute this test after competing piping work and airtight test but before starting

heat insulation work)

1. Piping connection

1) Connect the joint valve of the service piping (SPK-TU125) and the manifold gauge set

exclusively for CO

2

refrigerant by using a CO

2

charge hose or 1/4" pipe.

2) Connect a nitrogen cylinder and the manifold gauge set by using a CO

2

charge hose or

1/4" pipe.

2. Airtight test

1) Set the evacuation mode in accordance with " Evacuation Mode".

2) When carrying out an airtight test of interconnecting piping and load-side equipment

(such as showcase and unit cooler), set up the service valves with the front seat.

After replacing components of the refrigeration unit and when performing an airtight test of

the refrigeration unit, use the Mid-position. (The access ports are open.)

However, at this time, avoid applying the high-pressure side airtight test pressure to

the low-pressure side.

Note:

Airtight test of the refrigeration unit was completed at the time of factory

shipment. Pressure testing should only be carried out by personal / companies

who have necessary certification. Consider carefully local regulations and

EN378.

Design pressure in Factory

Caution

Make sure to close the vacuum valve of CO

2

manifold gauge set.

Consider special local regulations and consider Installation of all

equipment have to be in accordance to pressure directive 2014/68/EU

and European norm EN378.

Service piping

Joint valve

Nitrogen cylinder

Charging

valve

CO

2

charge hose or 1/4" pipe

CO

2

manifold gauge set

Low side

gauge

High side

gauge

High pressure part

Low and intermediate

pressure parts

12MPa

8MPa

Low pressure service valve

High pressure service valve

Содержание OCU-CR200VF5

Страница 37: ...37 Exploded View ...

Страница 38: ...38 Exploded View ...