- 7 -

NC-BH30P, BH40P

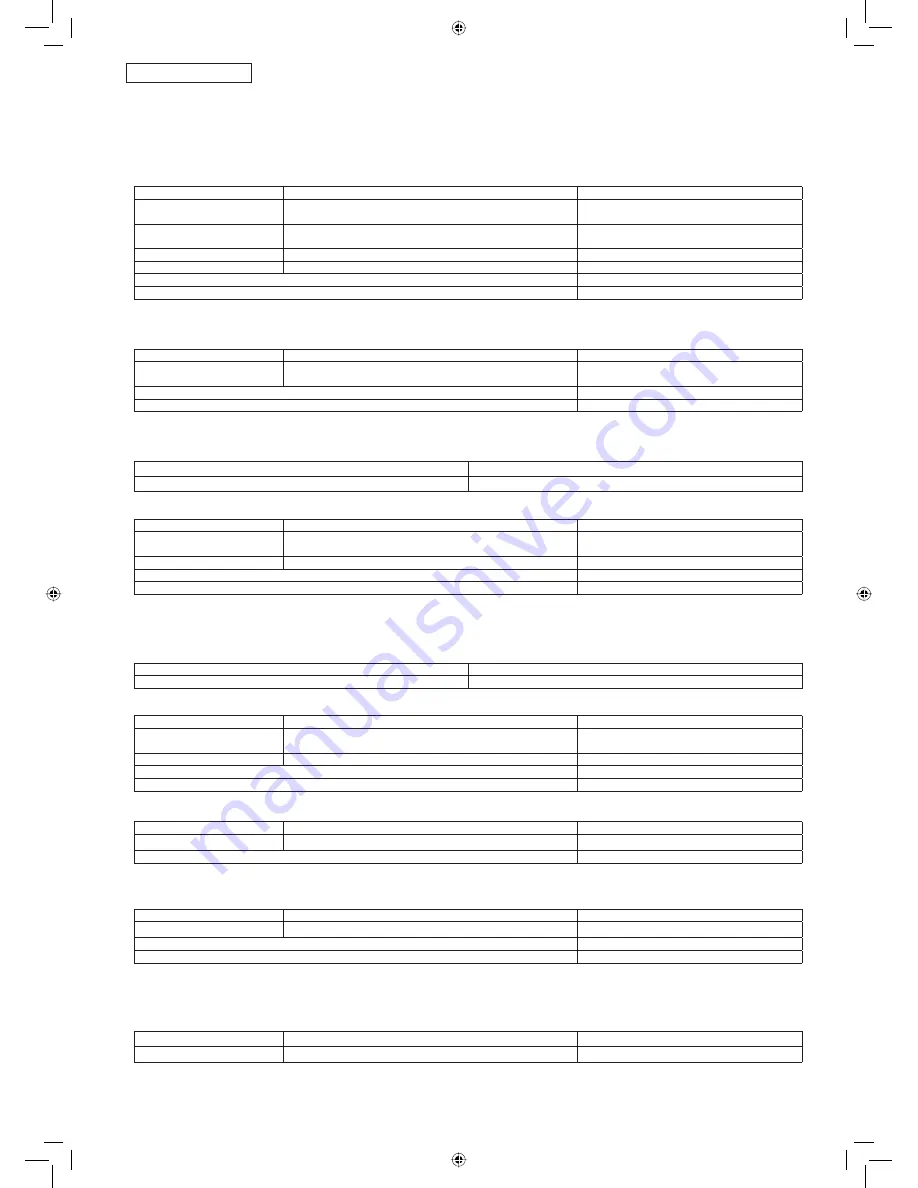

2.3. Failure Diagnostics Chart

2.3.1. No power. (There is no power indication.)

➞

Sections 2.4.1 to 2.4.7

describe electric power supply.

The items in the “Check” column correspond to those shown in Check Points on P.6.

Check

Diagnostics Method

Action

Thermal fuse comp.

Is there connection between the white lead wire on the peg

frame and the CN3 connector of the control unit A? (0

Ω

)

Replace the thermal fuse comp.

Keep warm heater

Is there connection across the boiling heater contacts?

(approx. 133

Ω

)

The container comp.

Power cord

Is there connection in the power cord? (0

Ω

)

Replace the power cord.

Lead wire assy. E comp.

Is there connection in the lead wire assy. E? (0

Ω

)

Replace the lead wire assy. E.

When the above parts are normal

Replace the control unit A (bottom)

When the above parts are normal

Replace the control unit B (operation)

2.3.2. Water is not boiling. (Water comes out.)

The items in the “Check” column correspond to those shown in Check Points on P.6.

Check

Diagnostics Method

Action

Water Heater

Is there connection between the white lead wire and

the red lead wire? (approx.14

Ω

)

Replace the container comp.

When the above parts are normal

Replace the control unit A (bottom)

When the above parts are normal

Replace the control unit B (operation)

2.3.3. Water does not come out, or water

fl

ow is restricted. (Water is boiling.)

Check point

Diagnostics Method

Action

Is the

fi

lter (located at the bottom of container) clogged?

Clean or replace the

fi

lter.

The items in the “Check” column correspond to those shown in Check Points on P.6.

Check

Diagnostics Method

Action

Electric pump

Turn on the 100V power, and press the Lock/Unlock pad

fi

rst

and then the Pour out pad. Is the motor heard running?

Replace the electric pump.

Lead wire assy. E comp.

Is there a miss-connection in the lead wire assy. E (0

Ω

)

Replace the lead wire assy. E.

When the above parts are normal

Replace the control unit B (bottom)

When the above parts are normal

Replace the control unit A (operation)

2.3.4. Reboil and Vacuum Keep Warm lamps illuminate alternately.

(Overheating protection mode/Bottom thermistor disconnection comp. mode)

Check point

Diagnostics Method

Action

Is there water inside?

Supply water and press Reboil pad.

The items in the “Check” column correspond to those shown in Check Points on P.6.

Check

Diagnostics Method

Action

Thermistor comp.

Is there connection between blue lead wire and blue

lead wire? (approx.45

Ω

at approx. 20°C)

Replace the thermistor comp.

Lead wire E comp.

Is there connection in the lead wire assy. E? (0

Ω

)

Replace lead wire E comp.

When the above parts are normal

Replace the control unit B (bottom)

When the above parts are normal

Replace the control unit A (operation)

2.3.5. The Select pad does not work

Check

Diagnostics Method

Action

–

–

Replace the control unit B (bottom)

When the above parts are normal

Replace the control unit A (operation)

2.3.6. The Lock/Unlock pad does not work.

The items in the “Check” column correspond to those shown in Check Points on P.6.

Check

Diagnostics Method

Action

Lead wire E comp.

Is there miss-connection in the lead wire assy E? (0

Ω

)

Replace lead wire E comp.

When the above parts are normal

Replace the control unit B (bottom)

When the above parts are normal

Replace the control unit A (operation)

2.3.7. Hot water does not dispense smoothly.

(Immediately after being boiled in particular) Boiling is too noisy.

Scale accumulation becomes severe inside the container.

Check

Diagnostics Method

Action

–

–

Clean with citric acid

NC-BH40-30-22.indd 7

NC-BH40-30-22.indd 7

14-08-07 16:47:59

14-08-07 16:47:59