9.3.5.

Scanner Condition

Item

Operation

Default

Remarks

Sleep Mode

1. Click “

Sleep Mode

“ on the main menu (Service Utility).

2. Set “

Sleep Mode

“ to enable or disable by checking check-box.

3. Set “

Waiting Time

“ (minutes) to change sleep mode.

4. Click “

OK

“ to renew the setting.

Enable

15minutes

Clean Imprinter

1. Click “

Clean Imprinter

“ on the main menu to clean a ink jet head to

print.

—

This item is available only in case

of installing Imprinter (Option) to

scanner KV-S2045C/SU245C

Series. (Not used to KV-

S2025C/SU225C Series)

Warning Setting

1. Click “

Warning Setting

“ on the main menu.

2. Change the parameters (Clean Roller Timing, Replace Roller Timing)

on “

Warning Setting

“ dialog box.

3. Click “

OK

“ to renew the setting.

Clean:

20000

Replace:

300000

Set Default

1. Click “

Set Default

“ on the main menu.

2. Click “

Set Default

“ on “

Set Default

“ dialog box to set “

Sleep Mode

setting“ and “

Warning Setting

to clean and replace roller“ to default.

3. Click “

Close

” to get back to the main menu.

—

9.3.6.

Test

Item

Operation

Default

Remarks

LED

1. Click “

LED

“ on the main menu.

2. Click “

START

“ on

LED

dialog box to start LED Test continuously until

clicking “

STOP

“.

3. Click “

Close

” to get back to the main menu.

—

Changing periodically

(Green — Orange — Red —

Green —....)

Key / Sensor

1. Click “

Key / Sensor

“ on the main menu.

2. Check key and sensor status on

Key / Sensor

dialog box. (Each

sensor “

ON

“ except for Door Sensor and STOP/START KEY means

paper existence in the scanner. Door Sensor “

ON

“ means opening

the door.)

3. Click “

Close

“ to get back to the main menu.

—

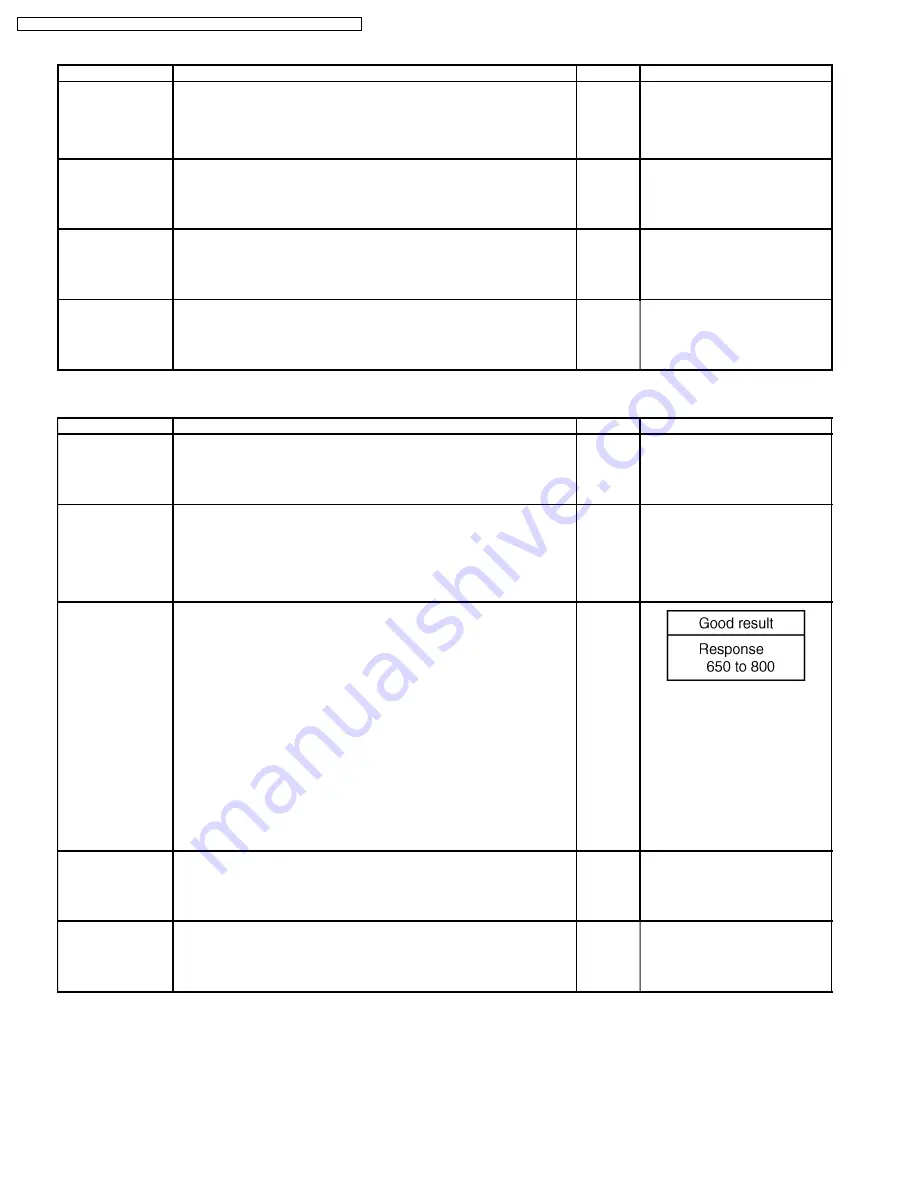

Sensor Sensitive

Level

1. Click “

Sensor Sensitive Level

“ on the main menu.

2. Check each sensor sensitive level on

Sensor Sensitive Level

dialog

box.

Note

As required, click “Adjust” on Sensor Sensitive Level dialog

box to renew three sensors’ (Waiting Sensor, Starting

Position Sensor, Ending Sensor) sensitive standard data to

judge whether paper exists or not correctly.

However, before this execution, the following cleaning is

needed.

a.

Waiting Sensor and its reflector sheet

b.

Starting Position Sensor and its reflector sheet

c.

Ending Sensor and its reflector sheet

3. Click “

Close

“ to get back to the main menu.

—

Feed Motor

1. Click “

Feed Motor

“ on the main menu.

2. Click “

START

“ on “

Feed Motor

“ dialog box to start to rotate Paper

Feed Motor continuously until clicking “

STOP

“.

3. Click “

Close

“ to get back to the main menu.

—

Conveyor Motor

1. Click “

Conveyor Motor

“ on the main menu.

2. Click “

START

“ on “

Conveyor Motor

“ dialog box to start to rotate

Conveyor Motor continuously until clicking “

STOP

“.

3. Click “

Close

“ to get back to the main menu.

—

64

KV-S2025C Series / KV-SU225C Series / KV-S2045C Series / KV-SU245C Series

Содержание KV-S2025C

Страница 93: ...12 2 POWER Board PbF stamp 93 KV S2025C Series KV SU225C Series KV S2045C Series KV SU245C Series ...

Страница 96: ...96 KV S2025C Series KV SU225C Series KV S2045C Series KV SU245C Series ...

Страница 114: ...KV S2025C Series KV SU225C Series KV S2045C Series KV SU245C Series 114 ...

Страница 116: ...14 1 Exterior 116 KV S2025C Series KV SU225C Series KV S2045C Series KV SU245C Series ...

Страница 118: ...14 2 Chassis and Base 118 KV S2025C Series KV SU225C Series KV S2045C Series KV SU245C Series ...

Страница 120: ...14 3 Hopper Unit 120 KV S2025C Series KV SU225C Series KV S2045C Series KV SU245C Series ...

Страница 122: ...14 4 Power Unit 122 KV S2025C Series KV SU225C Series KV S2045C Series KV SU245C Series ...

Страница 124: ...14 5 Packing 14 5 1 KV S2025C SU225C Series 124 KV S2025C Series KV SU225C Series KV S2045C Series KV SU245C Series ...

Страница 126: ...14 5 2 KV S2045C SU245C Series 126 KV S2025C Series KV SU225C Series KV S2045C Series KV SU245C Series ...