Chapter 4. Parts Replacement

8

DigitalFlow™ XMT868i Service Manual

4.7 Assembling/Installing the Circuit Board Assembly

Most of the parts replacement procedures described in this chapter require removal of the circuit board assembly

from the electronics enclosure. Furthermore, most of the procedures require varying degrees of disassembly of the

circuit board assembly. See Figure 9 on page 13 and follow the instructions in this section to assemble the circuit

board assembly and/or to install it in the electronics enclosure.

4.7.1

Assembling the Circuit Board Assembly

If the circuit board assembly has been disassembled to any degree, complete the steps below. Otherwise proceed

directly to

Installing the Circuit Board Assembly

on page 9. See Figure 9 on page 13 and complete the following steps:

1.

If necessary, replace the angle bracket on the main board, insert the screw (with flat washer and lock washer),

and screw it into the standoff on the main board. See Illustration 11 in Figure 9 on page 13.

IMPORTANT:

The small angle bracket on the terminal board must be positioned on the outside of the main board

with the previously removed nylon washer between them.

2.

Face the User Program side of the main board toward the rear of the power supply board. Orient the boards so

that the pins along the bottom of the main board align with connectors J2 and J6 on the power supply board,

and push the two boards firmly together.

Note:

If the thermal gap filler pad of the power supply board has been damaged, you must remove and replace it

before reinserting the power supply board. First, remove and discard the damaged pad. Then remove the

blue protective liner from the new pad and apply it with the white face against the power supply board.

3.

Secure the power supply board and heat sink to the main board by reinstalling the screws, flat washers and lock

washers previously removed from the corners of the power supply board. See Illustration 11 in Figure 9 on page 13.

4.

Refer back to Illustration 7 in Figure 8 on page 12. Carefully align the terminal board onto the main board/power

supply assembly and the two option boards (Slot 1 and Slot 2, where applicable), so that the connectors listed in

Table 5 are facing each other.

5.

Firmly press the terminal board and the interconnect board toward each other until all of the connectors are

completely seated.

IMPORTANT:

With two option cards installed, it may require some patience to get all of the connectors properly

aligned. Do not force the assembly together, or some of the pins may not enter the sockets properly.

6.

Secure the assembly together by installing the three mounting screws, flat washers and lock washers previously

removed from the terminal board. Be sure to install one end of the green grounding jumper wire under the screw

indicated in Illustration 7 in Figure 8 on page 12. The smaller screw should be used at the angle bracket location,

and secured with a nut, lock washer and flat washer.

Proceed to the next section for instructions on installing the reassembled circuit board assembly in the electronics

enclosure.

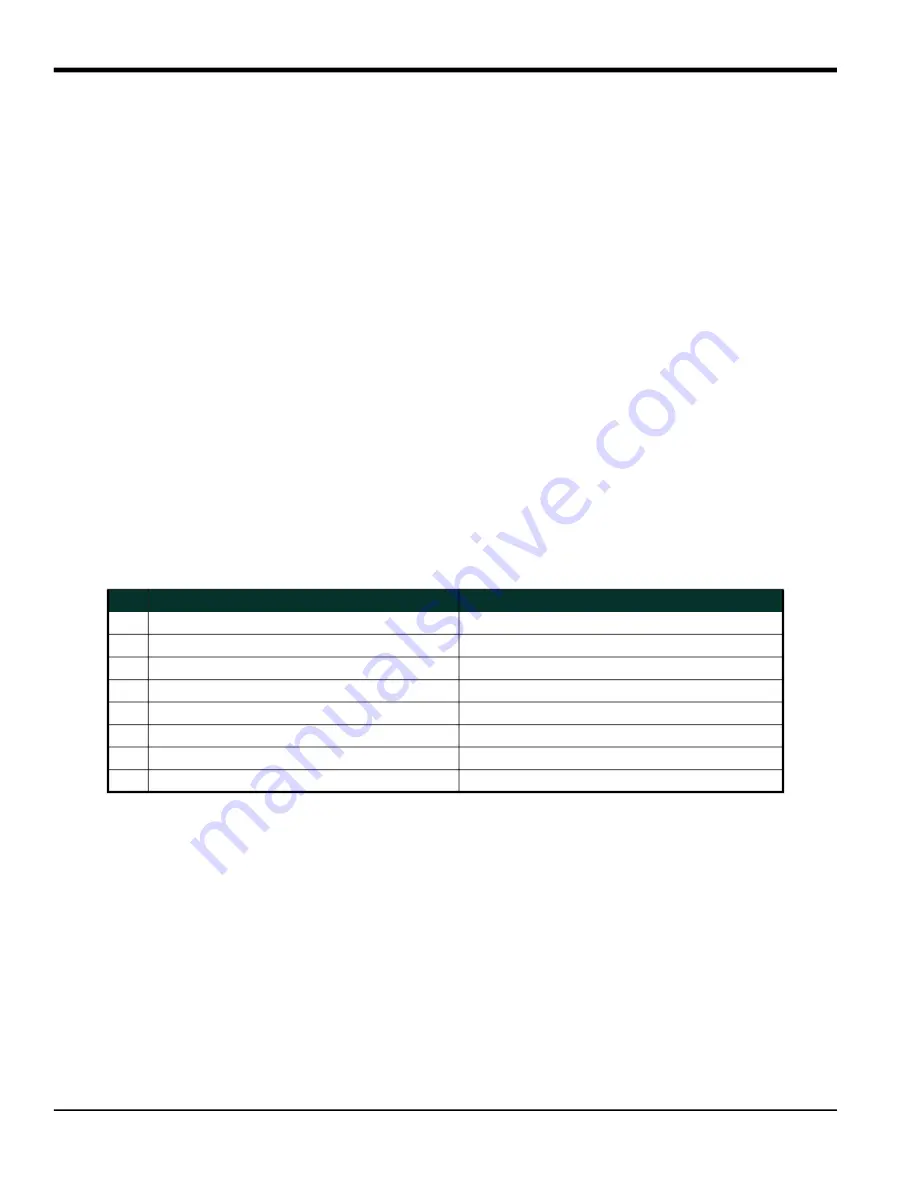

Table 5: Matings for Terminal Board

Terminal Board

Mating Board

1

J7 Connector (Large 3-Pin Connector Plug)

Power Tab on AC Power Supply Board

2

J6 Connector (Large 3-Pin Connector Plug)

Power Tab on DC Power Supply Board

3

P7 Connector

J7 Connector on Main Board

4

P10 Connector

J9 Connector on Main Board

5

P9 Connector

J10 Connector on Main Board

6

P8 Connector

J8 Connector on Main Board

7

P21 Connector

J1/J3 Connector on I/O Board, Slot 2 Option

8

P22 Connector

P2 Connector on I/O Board, Slot 1

Содержание DigitalFlow XMT868i

Страница 2: ......

Страница 4: ...ii no content intended for this page...

Страница 24: ...Chapter 2 Error Codes 4 DigitalFlow XMT868i Service Manual...

Страница 34: ...Chapter 3 Diagnostics 10 DigitalFlow XMT868i Service Manual...

Страница 44: ...Chapter 4 Parts Replacement 10 DigitalFlow XMT868i Service Manual...

Страница 48: ...Chapter 4 Parts Replacement DigitalFlow XMT868i Service Manual...

Страница 52: ...Appendix A Service Record 18 DigitalFlow XMT868i Service Manual...

Страница 66: ...Appendix B Calibration and Testing with PanaView 32 DigitalFlow XMT868i Service Manual...

Страница 72: ...Warranty 38 DigitalFlow XMT868i Service Manual no content intended for this page...

Страница 73: ......