•

Rotation of work table : Loosen table locking handle (Ref. No.

18) and rotate table (Ref. No. 13) to desired position and

retighten handle.

•

Tilting work table: Loosen table bolt (Ref. No. 10). Remove pin

and nut (Ref. No. 9). To do this, tighten nut until pin slips out easi-

ly. Tilt table to desired angle up to 45° and retighten table bolt.

Reinsert pin and nut when returning the table to 0° position.

•

To obtain more distance between chuck and table, the work

table can be rotated 180° and base can be used as a work sur-

face. This permits drilling of larger objects.

•

Clamp table securely after adjustments have been made.

DEPTH STOP ADJUSTMENT

Refer to Figure 8.

To control drilling depth, use scale (Ref. No. 16) to adjust to desired

depth. Depress and hold pin, slide depth stop nut (Ref. No. 15)

along lead screw until bottom edge of nut coincides with the

desired depth on the scale, then release pin. Use this feature to drill

more than one hole to the same depth.

MOUNT DRILL BIT

Refer to Figure 8.

WARNING:

Be sure drill press is turned off and is disconnected

from power source before adjusting speeds.

•

Place drill bit in jaws of drill chuck.

•

Tighten chuck with drill chuck key. Be sure to tighten the chuck

using all three key positions on the chuck body and remove

chuck key.

•

Use only the self-ejecting chuck key (Ref. No. 31) supplied with

this drill press, or a duplicate key. Use of any other key might

allow start up with the key still in the chuck. An airborne key

could strike the operator and cause injury.

REMOVE THE CHUCK

Refer to Figures 8 and 9.

•

Rotate quill feed handle (Fig. 8, Ref. No. 34) until slot is exposed

in the side of the quill (Fig. 8, Ref. No. 24). Lock quill in position

using handle (Fig. 9, Ref. No. 30).

•

Rotate spindle until inner slot is aligned with outer slot. You will

see through spindle when slots are properly aligned.

•

Insert the drift key (Fig. 8, Ref. No. 25) into the slots and tap

lightly with hammer. The arbor and chuck will drop from spindle.

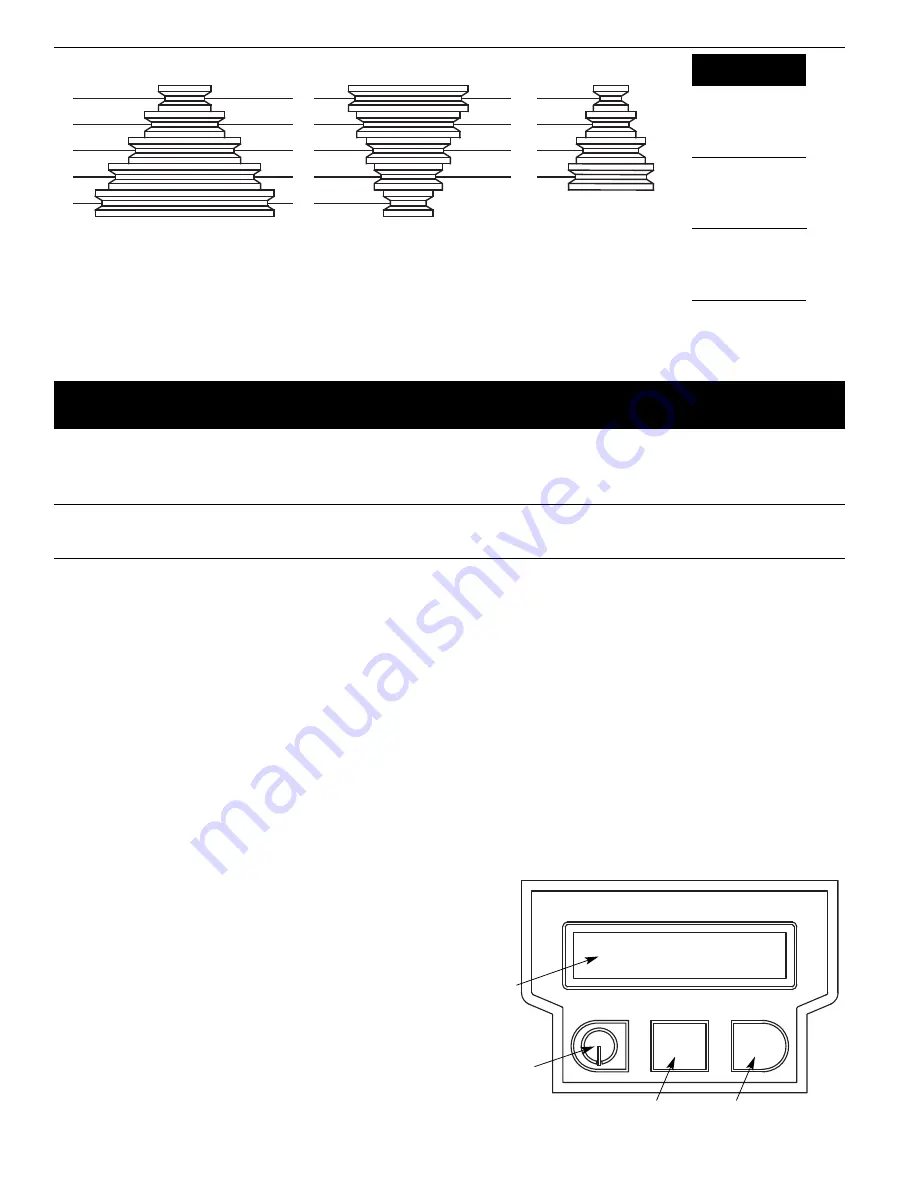

DIGITAL DISPLAY PANEL

Refer to Figure 6.

•

Display panel ‘A’ shows the depth of the spindle and spindle

RPM.

•

Button ‘B’ turns power on and off to Display ‘A’.

•

Button ‘C’: Press once for spindle depth in inches; press again

for spindle depth in mm; press once again for spindle RPM.

•

Button ‘D’ resets display at zero for spindle depth.

6

3476

2362

1660

566

497

344

257

in/mm

5/16

7.9

5/8

15.9

7/8

22.2

1

1

⁄

4

31.8

1

1

⁄

4

31.8

1

5

⁄

8

41.3

2

50.8

in/mm

3/16

4.8

3/8

9.5

1/2

12.7

3/4

19.0

3/4

19.0

7/8

22.2

1

25.4

in/mm

11/64

4.4

11/32

8.7

15/32

11.9

11/16

17.5

11/16

17.5

3/4

19.0

—

—

in/mm

5/32

4.0

5/16

7.9

7/16

11.1

5/8

15.9

5/8

15.9

13/16

20.6

—

—

in/mm

7/64

2.8

1/4

6.4

11/32

8.7

1/2

12.7

1/2

12.7

5/8

15.9

—

—

in/mm

3/32

2.4

5/32

4.0

1/4

6.4

3/8

9.5

3/8

9.5

1/2

12.7

—

—

in/mm

1/16

1.6

1/8

3.2

3/16

4.8

5/16

7.9

5/16

7.9

7/16

11.1

9/16

14.3

in/mm

1/32

0.8

1/16

1.6

1/8

3.2

1/4

6.4

1/4

6.4

3/8

9.5

1/2

12.7

RPM

Wood

Zinc Diecast

Alum. & Brass

Plastic

Cast Iron &

Bronze

Steel - Mild &

Malleable

Steel - Cast &

Med. Carbon

Steel -

Stainless

& Tool

E

D

C

B

A

Z

Y

X

W

5

4

3

2

1

Motor

Spindle

138

257

304

344

461

497

566

708

755

927

1491

1660

1761

2362

2444

3476

A1-5Z

B2-5Z

A1-4Y

C3-5Z

D4-5Z

A1-3X

B2-4Y

A1-2W

C3-4Y

B2-3X

E5-4Y

D4-3X

C3-2W

D4-2W

E5-3X

E5-2W

RPM

Belt

Location

Figure 5 – Spindle Speed Adjustment

Figure 6 – Digital Display Panel

ZERO

UNITS

A

B

C

D

0.000

mm

Palmgren Operating Manual & Parts List

80155 and 80156