12

A regular program of preventive maintenance for your

planetary hoist is required to minimize the need for emer-

gency servicing and promote safe, reliable hoist opera-

tion.

The user of Braden hoist products is responsible for hoist

inspection, testing, operator training and maintenance

noted below with frequency dependent upon the severity

of the hoist duty cycle and the thoroughness of the pre-

ventive maintenance program.

Field experience, supported by engineering tests, indi-

cate the three service procedures listed below are the

most critical to safe, reliable hoist operation and MUST

be observed.

•

Regular Gear Oil Changes (see notes 1 and 2 below

and page 13 of this manual)

•

Use of Proper Gear Oil – recommended type for pre-

vailing ambient temperatures and additives (see page

14 and 15)

•

Periodic Disassembly and Inspection of All Wear

Components – in compliance with ANSI specification

B30.5c, 1987 and API RP 2D.

1. The air motor case oil should be drained and refilled

with recommended oil after 25 hours initial running

and every 200 hours thereafter or sooner if neces-

sary; for example, if the oil is contaminated by water

in the air line.

2. The winch gear oil should be changed after the first

100 hours of operation or 30 days. The regular gear

oil change intervals may be adopted after the first oil

change.

3. The proper oil level in the motor casing (at level plug

on page 15), must be maintained. The frequency of

replenishment will depend on the application and

usage.

4. The air line filter should be drained at least once each

work shift and examined for clogging of the element.

Moisture in the air line that enters the motor will cause

accelerated motor wear. Moisture traps and air

receivers in the air system will help minimize moisture

in the air reaching the motor.

5. The air line lubricator should be replenished as

required and set to give 6 to 8 drops per minute. If

operation is intermittent, double the rate to 12 to 16

drops per minute.

Pre-use Inspection

(each shift the hoist is used): This

inspection must be performed prior to placing the crane

into service and then as necessary during the day for

extended operation.

1. Check for external oil leaks and repair as necessary.

This is extremely important due to the accelerated

wear that can be caused by insufficient lubricat-

ing oil in the hoist.

The winch drum gear oil level

must be maintained between the maximum and mini-

mum levels. The oil level should be visible in the lower

half of the sight glass or level with the oil level plug on

units without a sight glass. Use only recommended

lubricants. See Recommended Lubricants chart in

this manual. The air motor oil level should be at the

level plug.

2. Check the ratchet and pawl mechanism (if so

equipped) for proper operation and for full engage-

ment of the pawl with the ratchet wheel. Repair or

adjust as necessary.

3. Check air plumbing for damage, such as chafed or

deteriorating hoses and repair as necessary.

4. Visually inspect for loose or missing bolts, pins, keep-

ers or cotter pins and replace or tighten as necessary.

5. Inspect the full length of wire rope, rigging and all

sheaves according to the wire rope rigging, and crane

manufacturer’s recommendations.

6. A warm-up procedure is recommended at each start-

up and is mandatory at ambient temperatures below

+40°F (4°C). The hoist should be operated at low

speeds, hoisting and lowering with no load, several

times to circulate lubricant through the planetary gear

sets.

PREVENTIVE MAINTENANCE

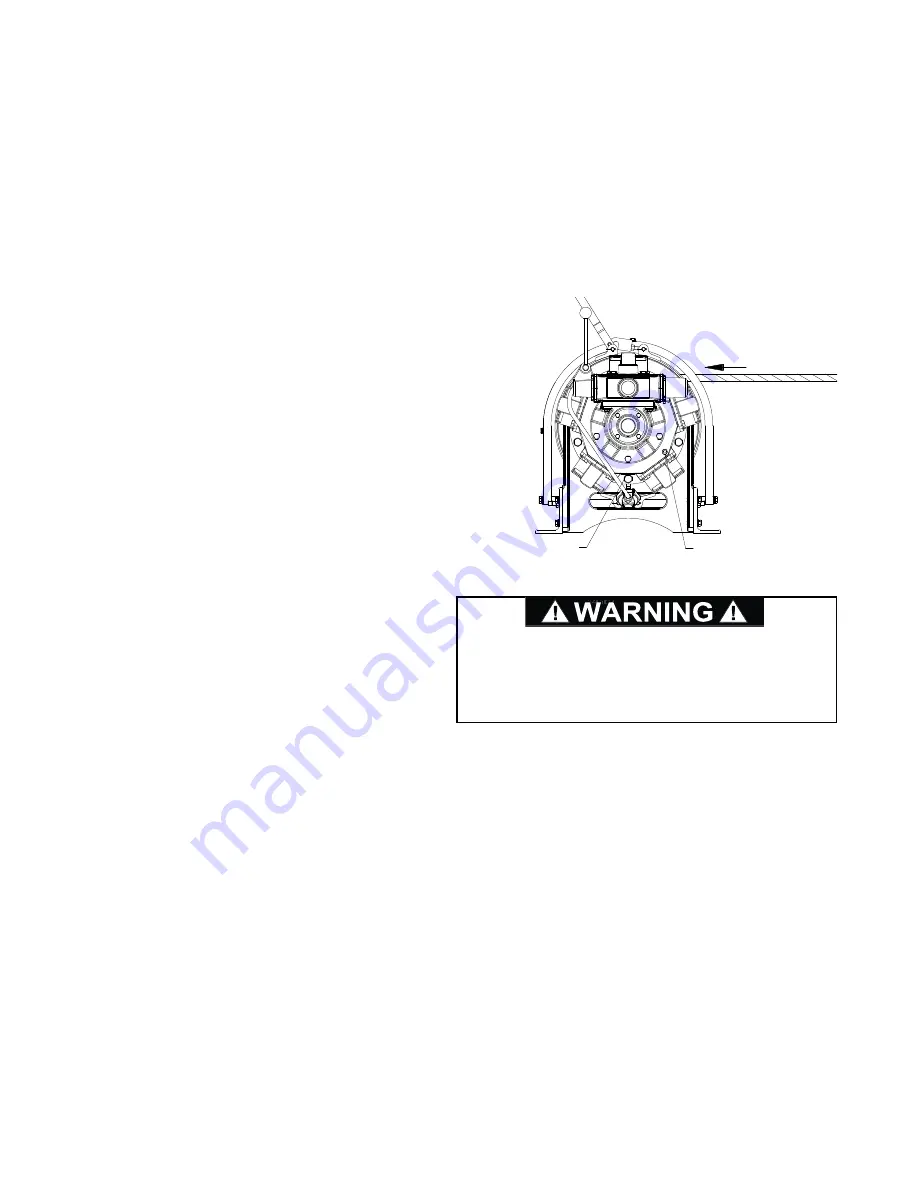

Motor

Oil Level

Motor Oil

Drain

HOIST

Failure to use the proper type and viscosity of plane-

tary gear oil may contribute to intermittent brake clutch

slippage which could result in severe personal injury,

death, or property damage.

Содержание BRADEN BA3A

Страница 2: ......

Страница 25: ...23 THIS PAGE INTENTIONALLY LEFT BLANK...

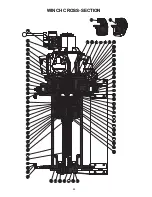

Страница 26: ...24 WINCH CROSS SECTION...

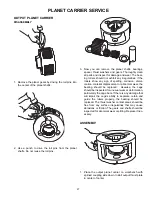

Страница 35: ...33...

Страница 37: ......