9

INSTALLATION

GENERAL REQUIREMENTS

1. The hoist must be mounted with the centerline of the

drum in a horizontal position. The mounting plane can

be rotated to any position around this centerline, pro-

viding the vent plug is positioned above the oil lev-

el. The vent plug must always be located above the

horizontal centerline of the hoist drum. If the hoist is

mounted on a pivoting surface, be sure the vent re-

mains above the centerline at all times. If necessary,

reposition the bearing support.

2. When mounting the winch, Grade 8, or better quality,

bolts and nuts are required. All mounting holes in the

hoist base must be used.

3. It is important that the hoist be mounted on a surface

that will not fl ex when the hoist is in use, since this

could bind the working parts of the hoist. Also, be

sure the hoist is mounted on a fl at surface. If neces-

sary, use shim stock to insure proper mounting. The

mounting surface should be fl at within ± .062 in. (1.5

mm).

4. Make certain that the hoist drum is centered behind the

fi rst sheave and the fl eet angle is not more than 1½

degrees or less than 1/2 degrees. The hoist should

also be mounted perpendicular to an imaginary line

from the center of the drum to the fi rst sheave to en-

sure even spooling. (ref page 7).

With the standard 24 inch wide (61 cm) winch drum,

the maximum distance to the fi rst sheave (1/2 degree

fl eet angle) is 115 ft. (35 m), and the minimum dis-

tance (1 ½ degree fl eet angle) is 38.2 ft. (11.7 m).

5. The air supply must be clean and free from moisture.

An airline fi lter and mist lubricator should be incorpo-

rated in the air supply line, located immediately before

the motor. The fi lter should have a moisture trap and

provide 20 micron fi ltration. If the rated performance

of the motor is to be obtained, all valves and pipework

must be of adequate size. For short pipe runs (up to 2

meters) the supply line should be the same size as the

motor ports and larger for longer runs. Valves should

be fi tted as close as possible to the motor.

6. Before connecting to the air supply blow out the air

lines to remove any loose scale, swarf or abrasive

dust which may be present.

7. When

fi rst running the motor, some light oil should be

injected into the inlet connection to ensure adequate

lubrication until the airline lubrication is established.

9. Ensure winch and air motor crankcase have been

8illed to the proper level with recommended oil.

9. Ensure dust shipping cups and plugs have been re-

moved from all air motor ports before operating the

winch.

DO NOT

install any detents or latching mechanism

that could hold the control valve in an actuated or run-

ning position when the operator releases the control

handle.

CAUTION

WARNING

!

!

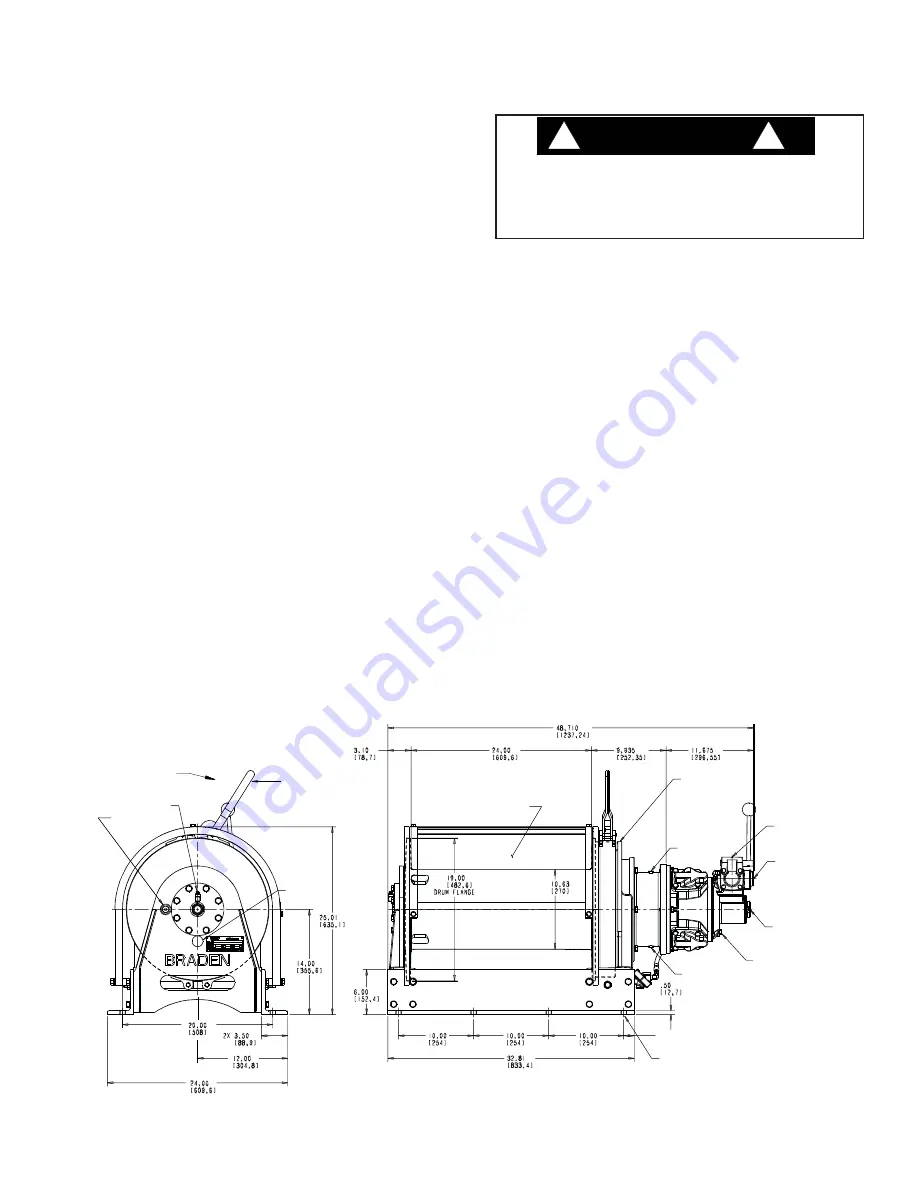

HAND BRAKE

LEVER

VENT

OIL FILL &

ACCESS HOLE

OIL DRAIN

ACCESS HOLE

GUARD EXPANDED METAL

NOT SHOWN FOR CLARITY

STEEL STAMP

MODEL NO. &

SERIAL NO.

THIS LOCATION

OIL FILL

MOTOR INLET PORT

1” - 11 1/2 NPT

VALVE EXHAUST PORT

1” - 11 1/2 NPT

MOTOR EXHAUST PORT

1 1/4 - 11 1/2 NPT

OIL DRAIN

MOTOR OIL LEVEL PLUG

8X .688 DIA.

MOUNTING HOLES

1.41

(35,7)

HOIST

All bolts must be Grade 8 or better 5/8 in.with hard washer under the nut. Torque to chart specifi cation on Page 13.

Содержание Braden BA2A

Страница 2: ...2...

Страница 25: ...25 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 26: ...26 WINCH CROSS SECTION...