OPERATION (cont.)

8

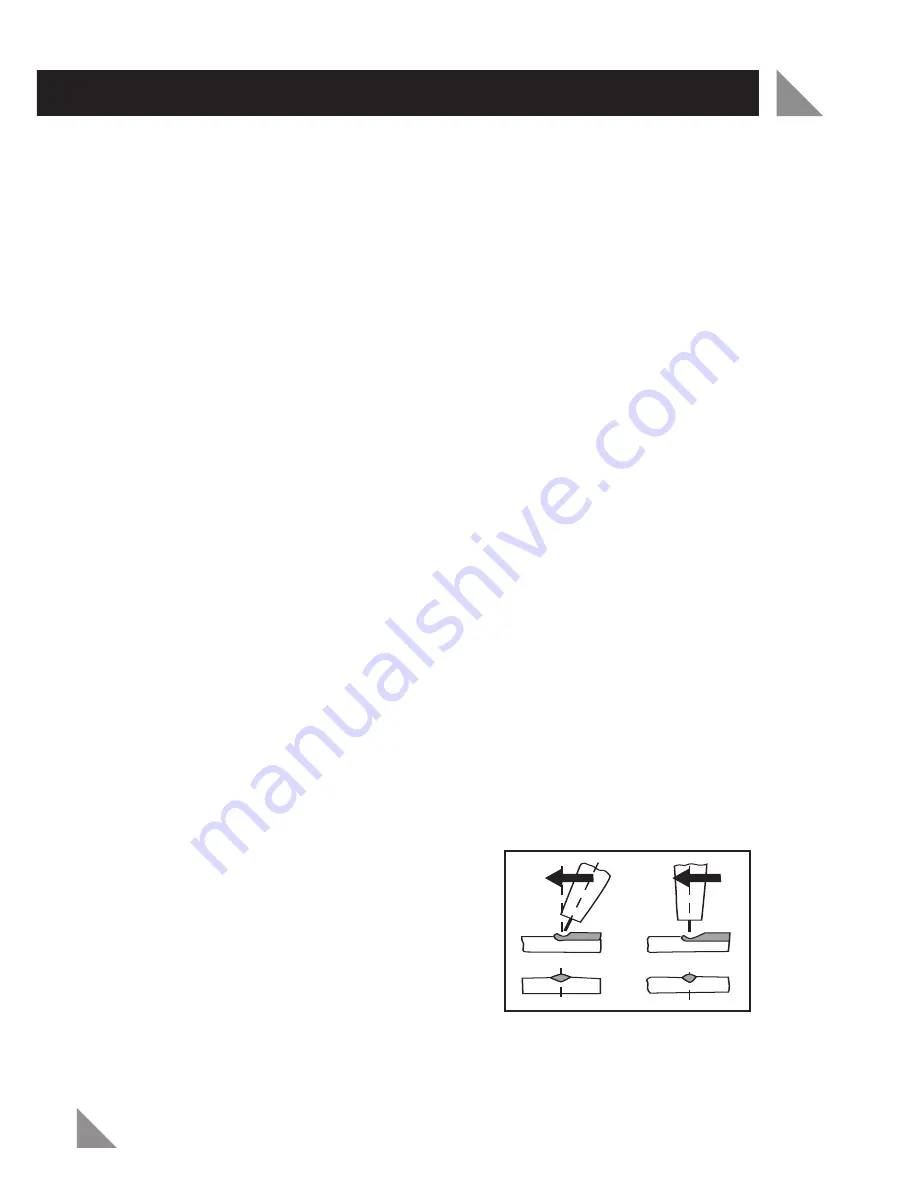

Fig 1

9. Take your welding tip and thread over the wire and screw onto the gun. Take

your shroud and screw over the welding tip. Using pliers to cut flush with

shroud end.

•

Position the two pieces of metal you wish to join.

•

Hold the mig torch approximately 2 cm away from the desired join area. Lower

or hold the welding mask over your face. Using the mig torch, proceed to

strike the wire tip against the desired join area on the work piece as if you are

striking a match. This is the correct strike up method.

Note:

Hitting the electrode on the work piece can damage the electrode and

make strike up difficult.

1. The welding power source has two main control settings. These are the wire

speed control and the current (amps) control.

2. The combination of these settings requires alteration depending on the

material and other conditions that affect the weld. It is advisable to practice

on scrap pieces of material to clarify which settings are going to give you the

best weld.

3. The wire speed and current control needs to be set at the correct speed and

power for a smooth and a consistent weld. There are many variables that

affect the weld including the style, speed of the operator, the material being

welded and the diameter of the wire.

4. When welding with large diameter wire it is advisable to use the high amps

setting selector on the front of the welder.

5. When welding with thinner diameter wire it is advisable to use the low amps

setting selector on the front of the welder.

If the Wire Speed is set too fast “stubbing” will occur as the wire dips into the

molten pool and does not melt. Welding in there conditions normally produces a

poor weld due to lack of fusion. If however the welding speed is too slow, large

drops will form on the end of the electrode wire, causing splatter. The correct

setting of wire speed can be seen in the shape of the weld deposit and heard by a

smooth regular are sound.

3.

Postion of MIG Torch

The angle of MIG

torch to the weld has an effect on the

width of the weld run. Refer to Fig 1.

4.

Distance from the MIG Torch Nozzle to

the Work Piece

The electrode stick out

from the MIG Torch nozzle should be

between 2.0mm to 5.0mm. This distance

may vary depending on the type of joint

that is being welded.

Forehand

Vertical