Praktika T-02(К) turnstile

16

4.4. Check the condition of the toothed belt and its tension (Fig. 8).

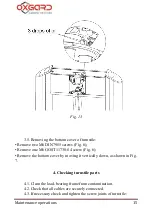

5. Lubrication of moving parts

Lubrication is made with 2-3 drops of engine oil (viscosity grade 5W-20).

5.1. The rotation axis of the stopper unit (Fig. 9).

5.2. The rotation axis of the roller lever (Fig. 10).

5.3. Clips between the stopper unit and the solenoid (Fig. 11). Elements

are located behind the roller lever shown on Fig. 10

5.4. The rotation axis of unlocking arms cam (Fig. 12).

5.5. The connection of lock pin and arms-unblocking cams (Fig. 13). The

operation shall be done for each arm. Hole in Fig. 13 is shown in the

conventional manner.

6.

Assembling and performance checking of the turnstile

6.1. If any troubles or defects are found out during MO it is advised

to contact our service department for advice, contact details are available

online:

www.oxgard.com

6.2. If it is necessary to repair damaged painted surfaces, powder

paint identical to the damaged (RAL9005) shall be used in accordance

with instructions for its use.

6.3. Reassemble the turnstile in reverse order.

6.4. Turn on the turnstile and perform functionality check by making

several passes and activating “antipanic” mode.

Содержание Praktika T-02

Страница 1: ...MAINTENANCE OPERATIONS www oxgard com info oxgard com Tel 7 812 366 15 94 Praktika T 02 К turnstile ...

Страница 2: ......

Страница 9: ...Maintenance operations 9 Fig 5 ...

Страница 10: ...Praktika T 02 К turnstile 10 Fig 6 ...

Страница 11: ...Maintenance operations 11 Fig 7 Fig 8 ...

Страница 12: ...Praktika T 02 К turnstile 12 Fig 9 ...

Страница 13: ...Maintenance operations 13 Fig 10 ...

Страница 14: ...Praktika T 02 К turnstile 14 Fig 11 Fig 12 ...

Страница 18: ...Praktika T 02 К turnstile 18 ...

Страница 19: ...Maintenance operations 19 ...