Содержание Praktika T-02

Страница 1: ...MAINTENANCE OPERATIONS www oxgard com info oxgard com Tel 7 812 366 15 94 Praktika T 02 К turnstile ...

Страница 2: ......

Страница 9: ...Maintenance operations 9 Fig 5 ...

Страница 10: ...Praktika T 02 К turnstile 10 Fig 6 ...

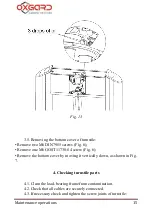

Страница 11: ...Maintenance operations 11 Fig 7 Fig 8 ...

Страница 12: ...Praktika T 02 К turnstile 12 Fig 9 ...

Страница 13: ...Maintenance operations 13 Fig 10 ...

Страница 14: ...Praktika T 02 К turnstile 14 Fig 11 Fig 12 ...

Страница 18: ...Praktika T 02 К turnstile 18 ...

Страница 19: ...Maintenance operations 19 ...