Page 5

If you don’t have a ruler handy

, another method of setting

the belt tension is to install the belt first. Do this by placing it

round the platter and then pull it onto the pulley, taking care

that there is no twist in the belt.

Now, lift the belt off the pulley and let it lose it’s tension

almost completely whilst still holding it gently - With no

tension whatsoever in the belt, you should stretch it approx

25mm to fit over the pulley. If this is not the case, move the

pod to achieve correct pulley position.

Alternative method of belt fitting (greyed text).

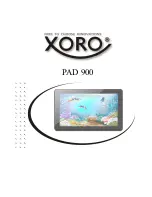

Refer to photos showing belt being fitted - Fit the belt over

the motor pulley and outer rim of platter. This is most

easily carried out by placing the belt over the pulley and then

holding it there loosely with one finger of your left hand.

Whilst retaining the belt on the pulley, hold the belt onto the

rear rim of the platter with the index finger of your right hand.

Now rotate the platter slowly clockwise with your right hand

index, all the time pressing the belt on the rim, till the belt is

completely on. Allow the motor pulley to rotate under your

finger whilst retaining the belt on the pulley and maintaining

slight tension on the belt between the pulley and rear of

platter.

The belt has an ideal tension for best performance - too

tight and motor bearing friction increases causing possible

speed instability and increased wear plus a decrease in sonic

performance. The correct distance is not hypercritical to

performance and the above dimensions may need to be

increased after a year of use due to belt stretch. Experiment

with different distances if you wish for best sound but you will

need to adjust speed between different distance settings, as

speed varies slightly with different belt tension.

You can fine tune this just by listening to the sound with the

pod in slightly different positions.

If the belt falls off the platter on start up you may need to

lower the turntable if the feet are adjusted too far down. Also

you can try increasing belt tension by moving the pod away

from the platter.

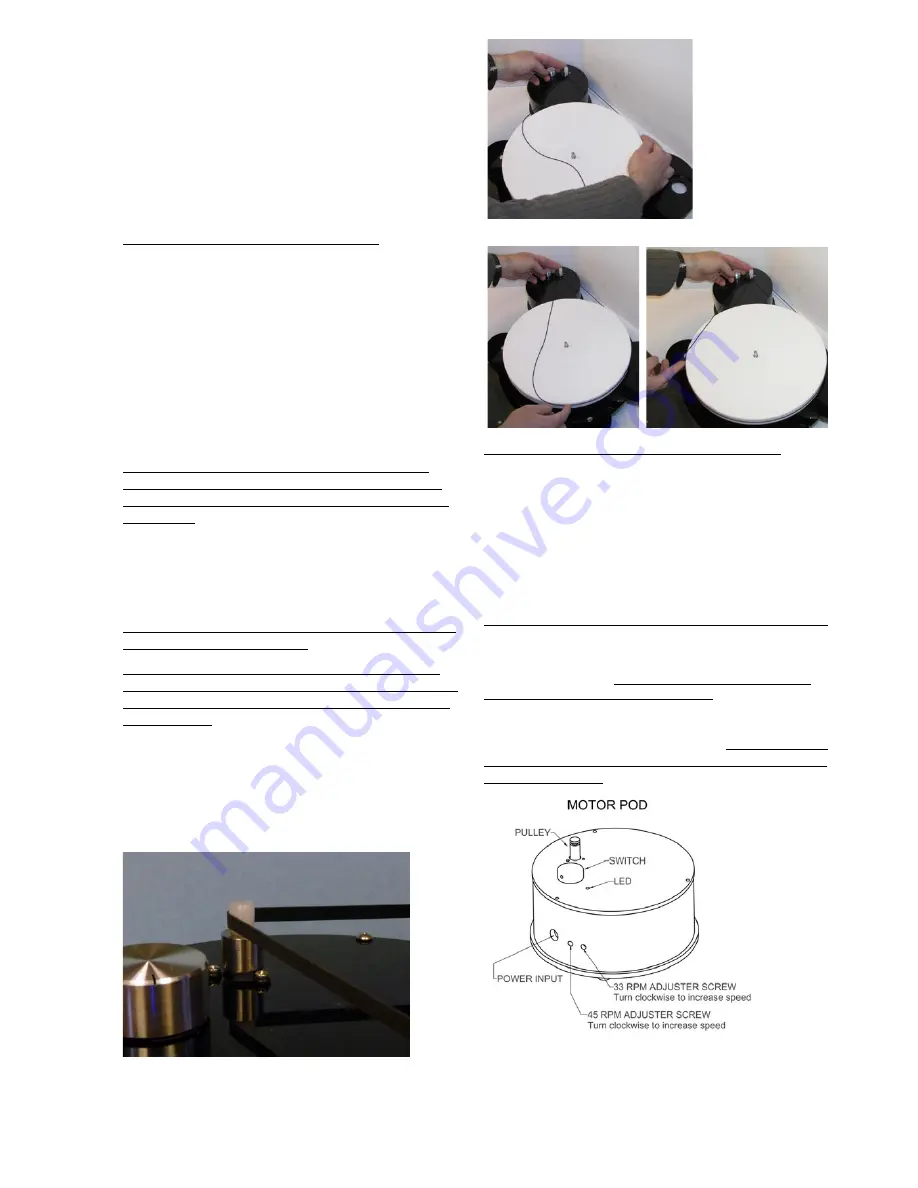

Insert the power supply jack plug into the pod’s largest side

hole. The LED on the top of the pod will light up. Note: green

LED is advanced supply and Blue LED is Ultra supply.

Sometimes the pulley has 2 curved surfaces to run on - this is

not for an additional belt ( which is not an advantage on OL

decks) but is to allow for different deck heights.

BELT ON PULLEY

Do not plug the power supply into mains conditioners, filters

or anything with surge protection - this can be disastrous

to performance. The aforementioned items will not harm

the pod, but they almost always results in performance

degradation.

The location of the motor pod should preferably be kept

away from strong electromagnetic fields typically generated by

transformers, amplifiers, power supplies etc.

S E T T I N G T H E M O T O R S P E E D

You will need to set the motor speed yourself. In the first 72 hours

of continuous running the motor, the speed tends to drift but then

settles down permanently.

Motor running should be carried out

with platter turning (no faster than 45rpm).

The thin output wires from the transformer only carry a very

low voltage and are therefore safe to handle. Voltages inside the

transformer are dangerous so the transformer case must not be

unscrewed or opened.

(At front or rear)

When the rotary switch on the pod is turned fully anti-

clockwise and the line on the knob aligns to the LED, the

motor is off.

Содержание Aurora MKII

Страница 9: ...Page 9...