3

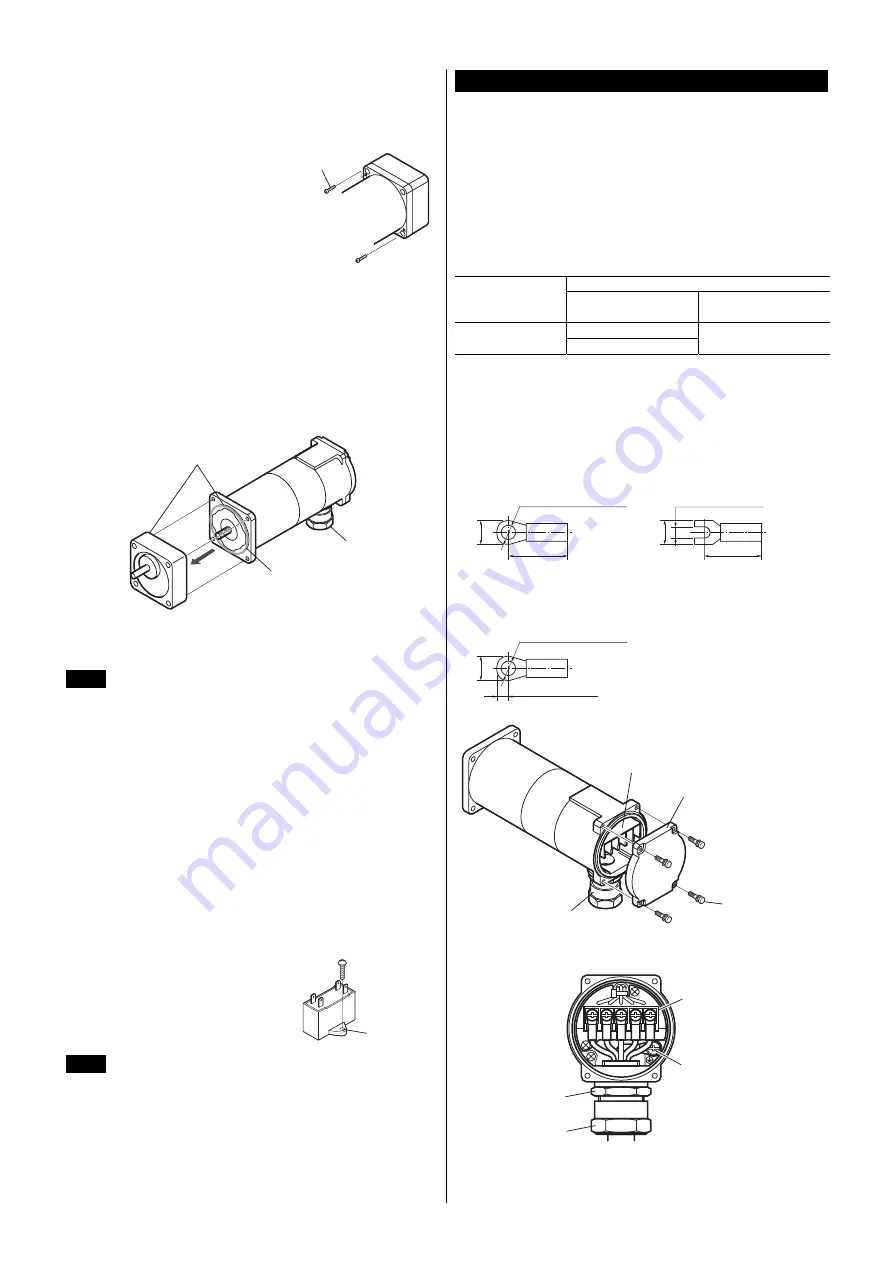

Installing/removing the gearhead

The gearhead can be removed and the cable gland position changed to a

desired 90° direction. The same procedure is followed when replacing the

gearhead.

1.

Remove the hexagonal socket head

screws (2 pcs.) assembling the motor

and gearhead and detach the motor

from the gearhead.

Hexagonal socket

head screw

2.

Using the pilot sections of the motor and gearhead as guides, install the

gearhead to the motor.

At this time, the cable gland position can be changed to a desired 90°

direction. When installing the gearhead, slowly rotate it clockwise/

counterclockwise to prevent the pinion of the motor output shaft from

contacting the side panel or gear of the gearhead.

This flange surface is constructed to hold a O-ring. If this O-ring comes

out of the flange groove, reseal it correctly on the flange groove.

Also confirm that no gaps remain between the motor flange surface and

the end face of the gearhead’s pilot section.

Gearhead

Motor

Pilot

O-ring

Cable gland

After assembling the motor with the gearhead, install the motor/gearhead

assembly using mounting screws by referring to the explanation under

“Combination type”.

Note

•

Do not forcibly assemble the motor and gearhead. Also,

do not let metal objects or other foreign matters enter the

gearhead. The pinion or gear of the motor output shaft

may be damaged, resulting in noise or shorter service

life.

•

Do not allow dust to attach to the pilot sections of the

motor and gearhead. Grease may leak from inside the

gearhead.

•

The hexagonal socket head screws used to assemble

the motor and gearhead together only tentatively secure

the two components. Always use the four supplied

mounting screws when installing the motor/gearhead

assembly.

Pinion shaft type

Pinion shaft type motors are used with a gearhead assembled.

Refer to figure above.

Mounting the capacitor (only for single-phase motors)

Before mounting the provided capacitor,

check that the capacitor’s capacitance

matches that stated on the motor’s name

plate. Mount the capacitor securely by using

M4 screws (not provided).

Ø4.3 mm

(Ø0.169 in.)

Note

•

Do not let the screw tightening torque exceed 1 N·m

(8.8 lb-in) to prevent damage to the mounting foot.

•

Mount capacitor at least 10 cm (3.94 in.) away from the

motor. If it is located closer, the life of the capacitor will

be shortened.

Connection

Insulate all the wire connections, such as the connection between the motor

and the capacitor connection.

For safety’s sake, install a breaker or fuse in the power line.

Ground the motor using a Protective Earth Terminal.

The rotation direction is as viewed from the side of the motor’s output shaft.

The motor rotates in a clockwise (CW) and counterclockwise (CCW) direction.

Rotating direction of the gearhead output shaft

The rotating direction of the gearhead output shaft may be opposite that of

the motor shaft, depending on the gear ratio. Before performing wiring, be

sure to check the rotating direction of the gearhead output shaft to be used

and determine the desired direction of motor rotation.

Gear ratio

Gearhead model

∗

Same as the rotating

direction of motor shaft

Opposite the rotating

direction of motor shaft

3 to 18

2GN S

50 to 180

25 to 36

∗

The box ( ) of the model will be filled with the numeral to represent the

gear reduction ratio.

Connection method to a terminal box

When connecting the cable (not supplied), use the following crimp terminal.

•

Applicable crimp terminal [unit: mm (in.)]

For terminal block

Insulated round terminal

Ø3.6 (Ø0.142) or more

18 (0.71) or less

7.2 (0.283) or less

Insulated fork terminal

3.6 (0.142) or more

18 (0.71) or less

6.4 (0.252) or less

For Protective Earth Terminal

Insulated round terminal

Ø4.1 (Ø0.161) or more

4.5 (0.177) or less

9 (0.354) or less

Terminal block

Terminal cover

Terminal cover

installation screw

(With spring washer)

Cable gland

•

Layout of terminals

Tightening nut

Nipple

Protective Earth

Terminal (M4)

Terminal block (M3.5)