4

Connection

Insulate the connection part of the power supply.

Be sure to ground using the Protective Earth Terminal

inside the terminal box.

Note

Be sure to use the screw for protective earth terminal attached on the

product.

Connection diagram

CAUTION

The motor does not have a built-in overheat protection

device.

Use an electromagnetic switch to prevent the motor from

burning when an overload is applied or the output shaft is

locked. (Refer to p.5 for details.)

The figure shows a connection diagram when the motor is directly connected to a power

supply.

The symbols U, V, and W represent the terminal symbols inside the terminal box.

[Electromagnetic switch]

MC: Electromagnetic contactor

THR: Thermal relay

MC

MC

MC

THR

THR

[Measures for surge voltage]

Connect the CR circuit for surge suppression to

protect contacts as shown in the figure.

R

0

C

0

•

When the motor rated voltage is 200 to 240 VAC

R

0

= 5 to 200

Ω

C

0

= 0.1 to 0.2 µF 250 VAC

This is provided as a peripheral equipment (sold

separately).

Model:

EPCR1201-2

•

When the motor rated voltage is 380 to 415 VAC

R

0

= 5 to 200

Ω

C

0

= 0.1 to 0.2 µF 450 VAC

z

Combination type-parallel shaft gearhead, round shaft type

The output shaft rotates in the following direction if connected as shown in the figure.

Gear ratio

5

,

10

,

15

,

20

,

100

, and round shaft type: CW (clockwise direction)

Gear ratio

30

and

50

: CCW (counterclockwise direction)

Check the motor model name and gear ratio before connecting.

To change the direction of rotation, change any two connections

between R, S and T.

CW

R

0

C

0

L2(S)

L3(T)

L1(R)

MC

MC

MC

THR

R

0

C

0

R

0

C

0

THR

Grounding

W

V

U

z

Combination type-right angle hollow shaft hypoid gear

GV

gearhead

The output shaft rotates in the counterclockwise direction (CCW) if connected as shown in

the figure.

To change the direction of rotation, change any two connections

between R, S and T.

CCW

R

0

C

0

L2(S)

L3(T)

L1(R)

MC

MC

MC

THR

R

0

C

0

R

0

C

0

THR

Grounding

W

V

U

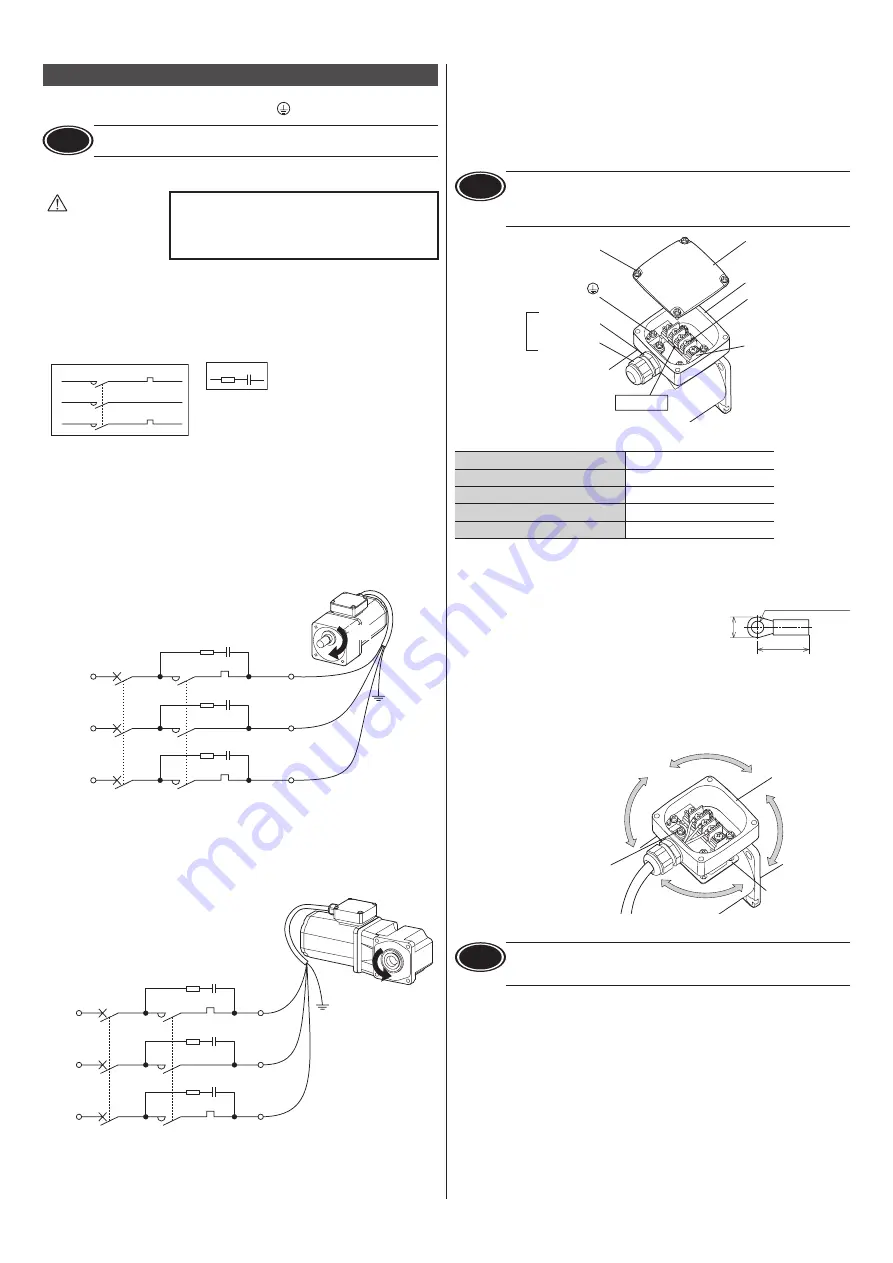

Connecting to the terminal block

Remove the terminal box cover to connect a cable.

Cables for connection are available as peripheral equipments (sold separately).

•

If the O-ring having set on the matching surface of the terminal box cover was detached,

install it firmly in the groove of the terminal box cover.

•

After connecting the cable, securely tighten with the tightening torque shown in the

table below.

Note

•

To maintain the sealing performance of the terminal box, keep the

applicable cable diameter and the tightening torque for screws.

•

Secure the cable exposed to the outside of the motor so that no stress is

applied.

Terminal block

Terminal box cover mounting

screw (M4-4 pieces)

Terminal box cover

Mounting screw

for terminal (M4)

Terminal box

Nipple

Tightening nut

Protective Earth Terminal

Cable gland

U V W

Terminal codes:

Tightening torque

Terminal box cover mounting screw

1.0 to 1.5 N·m (8.8 to 13.2 lb-in)

Mounting screw for terminal

1.0 to 1.2 N·m (8.8 to 10.6 lb-in)

Tightening nut

2.0 to 2.5 N·m (17.7 to 22 lb-in)

Nipple

2.0 to 2.5 N·m (17.7 to 22 lb-in)

Protective Earth Terminal

1.0 to 1.5 N·m (8.8 to 13.2 lb-in)

•

Use the following cable and crimp terminal when connecting the cable on the terminal

block.

Applicable crimp terminal: Round crimp terminal with

insulation cover

Applicable cable diameter: Ø7 to Ø13 mm

(Ø0.28 to Ø0.51 in.)

*

Applicable lead wire: AWG18 (0.75 mm

2

) or thicker

*

Round shaft type: Ø8 to Ø13 mm (Ø0.31 to Ø0.51 in.)

Ø4.3 (0.17) or more

[Unit: mm (in.)]

18 (0.71) or less

8 (0.31) or less

z

Changing the cable outlet position

The cable outlet position can be changed to the left or right 90-degree direction or the

180-degree direction.

When changing the cable outlet position, loosen the terminal box cover mounting screw,

rotate the terminal box to change the mounting direction.

Terminal box mounting screw

(M4-4 pieces)

Tightening torque:

1.0 to 1.5 N·m (8.8 to 13.2 lb-in)

Terminal box

Motor case

Gasket

Note

•

Be sure to use the gasket attached.

•

Assemble so that foreign objects are not entered between the terminal box

and the motor case.