BTP-R880NP Installation manual

sensitive side will turn black.

The paper on the roll should be tightly wrapped when loading the roll in the

printer.

The paper roll should be loaded straight in the printer and not slanted. In this

way the roll will not be obstructed from rolling during printing.

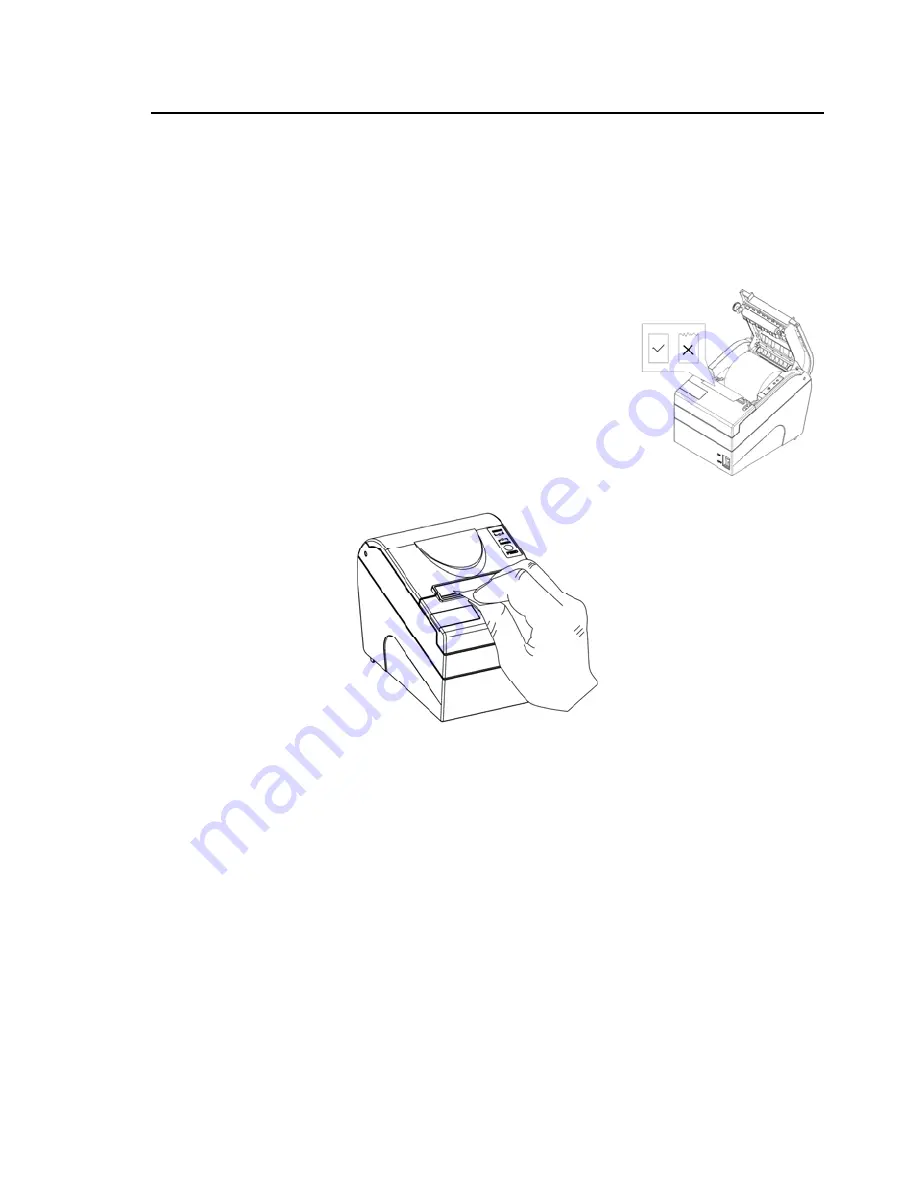

4) Pull the end of the paper roll out up to the end of the top cover, and close the

printer cover completely See figure below.

Caution:

The top cover must be closed completely, failure to

do so will influence the normal operation of the

printer.

5)

Tear off the surplus portion of the paper by using the

tear bar.

Caution

:

When encountering a cutter malfunction due to a paper jam or due to an

unexpected power loss, do not open the top cover of the printer by force since

the moving blade of the cutter might have blocked the cover. Failing to do so

might damage the moving blade of the cutter. In case the moving blade is

blocking the cover of the printer, follow the instructions below to solve the

problem.

1) Switch the printer off and on again. The moving blade might be able to move to

its home-position, which enables opening of the top cover, If this does not

occur and the top cover is still stuck, than continue with the next steps.

2) Switch off the printer and disconnect the power adapter from the printer.

3) Remove the cutter cover as shown in figure below, which will expose a small

wheel-knob.

- 9 -