4

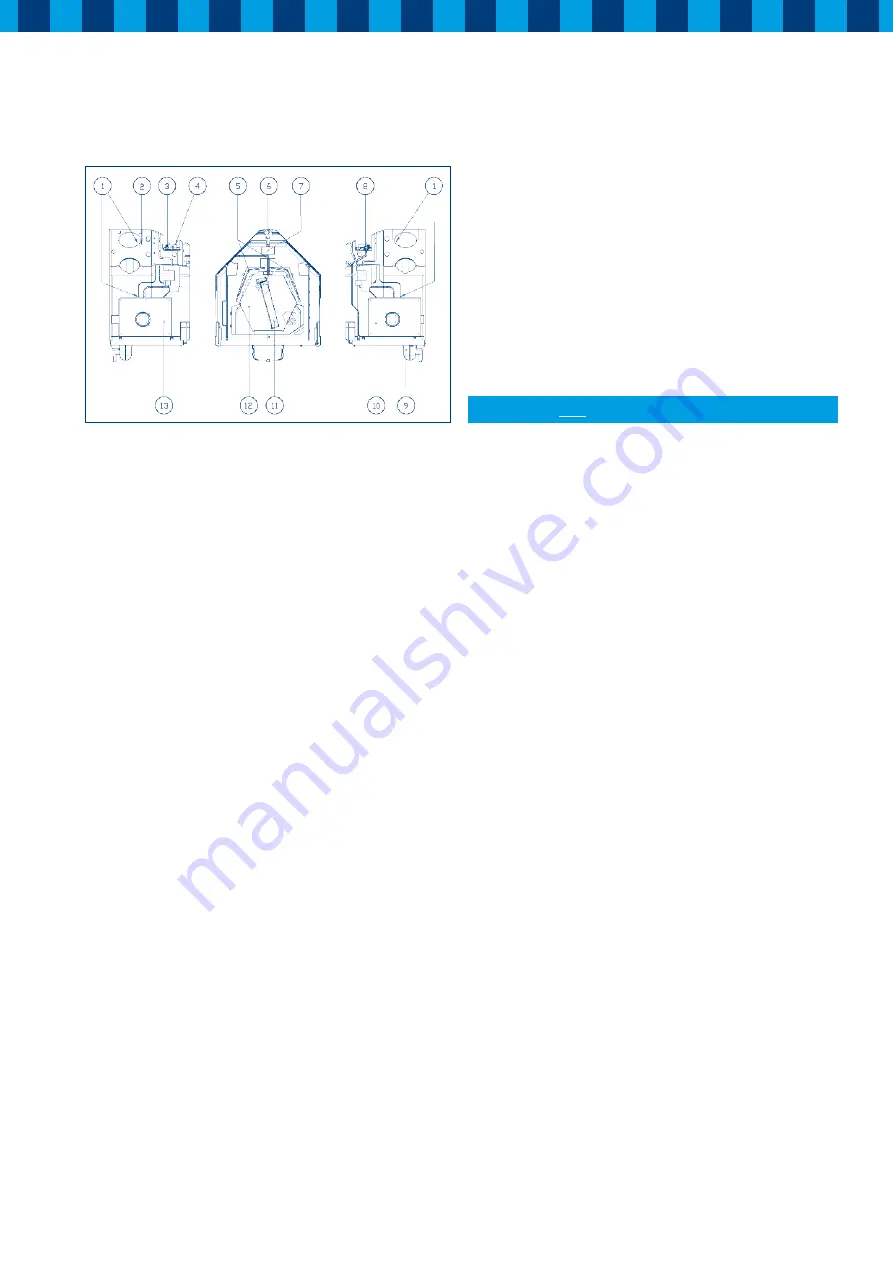

Fitting and maintenance instructions HRC 300/400 4B(P/RH)

3. Installation

1.

Temperature sensor (4x)

Measures the temperatures in all connected ducts

2.

Humidity sensor

Measures the relative humidity in the exhaust air

3.

Central PCB ( 3.1)

This pcb controls the fans, sensors and decides which

function is activated

4.

Dip switches

Used to adjust the airflow for each speed setting

5.

Filters

Both supply and extract air is filtered

6.

Left/Right module

For left or right-handed orientation (house-tree / tree-house)

7.

Display Panel

Displays the current status and any failure of the HRC

8.

Receiver PCB (only RH)

Pcb for wireless remote controlled HRC

9.

Condensate-trap

Connection for condensate drain with water trap

10. Fan Right

Constant Flow fan with brushless EC motor supplies fresh

filtered air to the dwelling or extracts stale air from the

building depending on selected orientation of the HRC

11.

Bypass valve

For supply of cool outside air in the summer

12.

Heat exchanger

Takes care of the heat exchange between both airflows

13. Ventilator module left

Constant Flow fan with brushless EC motor supplies fresh

filtered air to or extracts stale air from the dwelling depending

on selected orientation of the HRC.

3.1 Mounting frame

The mounting frame of the HRC can be fitted directly to the wall

with the delivered screws and plugs. The distance between both

mounting-holes will be 53 cm. Under the mounting frame

ensure there is at least 50 cm for the condensate discharge

to be connected. On the mounting frame is a drawing, which

indicates where to fit the condensate discharge. The position

of the electrical power supply (an earthed wall socket or fused

switched spur) is also indicated. The unit must be secured

horizontally. Ensure sufficient angle for the condensate

discharge. The installation must be in a frost-free room.

Make sure there is a free space of at least 80 cm at the front of the

appliance for cleaning the filter and carrying out maintenance

on the appliance.

3.2 Important instruction

The HRC unit must be installed in accordance with all relevant

Building Regulations and Health & Safety requirements and the

fitting instructions of the HRC 300/400 4B(P/RH)

Connect mains

after

mounting the ducts!

3.3 Connecting ducts

When the mounting frame is fitted, the ducts can be fitted.

On one side of the unit the duct to and from the dwelling, on

the other side the ducts from and to outside.

To prevent condensation on the outside of the exterior air,

the inlet duct and the air outlet duct from the HRC must be

insulated.

It is recommended that the ducts from and to the dwelling

and to the appliance use flexible ducting with a minimum

length of 150 cm and flexible connections of the ducts to and

from the outside to the appliance use flexible ducting with

a minimum length of 50 cm. Flexible ducting should be fully

extended but should not place any strain on the terminal or

fixings.

Remember when sizing the ducts that this part of the installation

will affect energy efficiency. So remember that energy will be

wasted, during the passage of the air through the ductwork,

if the ducts are too small. If possible ensure that the total

resistance of the inlet- as well as the exhaustsystem does not

exceed 100 Pascal.

Figure 1: Parts of heat recovery module HRC 300/400 4B(P/RH)