Version 1.2.3 - 2021-11-02

76

Translation of original instruction

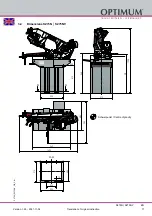

S275N | S275NV

EN

S275

N

_S275

NV_G

B_3.

fm

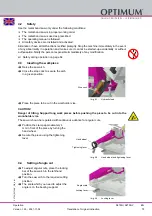

CAUTION!

Install the connection cable of the machine in such a way that people will not stumble

over it.

Connect the three-phase electric cable to the machine.

Check the fusing (fuse) of your electrical supply.

Fusing 10A - 16A

ATTENTION!

Ensure that all 3 phases (L1, L2, L3) and the ground wire are connected correctly. The

neutral conductor (N) of its power supply is not connected.

If the machine is already equipped with a three-phase connector, when connected to

your rotary power the rotation direction can be wrong.

3.6.2

Electrical connection S275NV

CAUTION!

Install the connection cable of the machine in such a way that people will not stumble

over it.

The machine is installed and ready to operate. Please verify if the type of current, voltage and

protection fuse correspond to the values specified. A protective earth ground wire connection

must be available. Main Fuse 16A.

Protective earthing conductor current

The earth leakage current of the inverter may exceed 3.5 mA AC. Due to this, a fixed earth

connection is required and the minimum size of the protective earth conductor shall comply with

the local safety regulations for high leakage current equipment. The inverter has been designed

to be protected by fuses; however, as the inverter can cause a DC current in the protective

earthing conductor, if a Residual Current Device (RCD) is to be used upstream in the supply,

observe the following:

The single phase AC 230 V inverters (filtered or unfiltered) can be operated on a type A1) 30

mA or type B(k) 30 mA RCD.

3.7

First commissioning

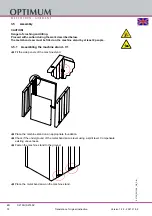

WARNING!

The machine may only be commissioned after proper installation.

When first commissioning the metal band saw by inexperienced staff you endanger

people and the machine. We do not accept any liability for damages caused by

incorrectly performed commissioning.

CAUTION!

Danger of cutting, perform the works described hereunder with care. Use the prescribed

protective equipment.

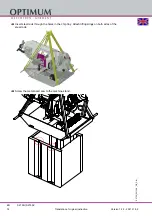

Inspecting the belt guide pulleys

Check if the saw blade is mounted correctly onto the belt guide pulleys.

Check that the saw belt fits snugly inside the guide bearings.

Check the tension of the saw belt. Proper blade tension is reached when the saw band has

been stretched to the green mark on the gauge.