Eco Online™ Solar Pool Heating System -- Installation Manual

© Copyright 2012 Optex Solar Pty Ltd. All rights strictly reserved.

Page 22

19

Collector Array Plumbing Connections

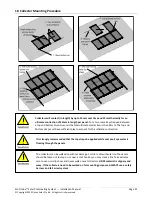

BEFORE CUTTING - put aside two collectors per row with undamaged end

caps.

For all remaining collectors cut the single end cap off using a sharp blade.

Check all collector pipe connections for raised edges or grooves on the weld

lines which could channel water and cause leaks. Shave any edges or grooves

flat with a blade being careful not to cut into the pipe.

After inserting silicon joiners and hose clamps moderately tighten the clamps

using a hand screwdriver

with an 8mm hex socket.

Do not glue in silicon joiners

as this allows for some collector contraction movement over time. If there is a

pin hole leak, a small amount of silicon can be used to seal.

The inlet/outlet adapter PVC barbs should be glued into the silicon joiner with

any neutral cure silicon

. A flat spatula type surface should be used to push

silicon into the barbs indentations (as shown).

Why? PVC barbs can soften at extreme roof stagnation temperatures and

contract sightly with clamps pressure. HDPE will not soften significantly at

maximum roof stagnation temperatures.

Laceration hazard: Always cut away from your body and

ensure no parts of the body are in front of the cutting blade.

DO NOT

perform this task when you are tired or in a rush.

Plastic can be softened by heating.

Do not over tighten hose clamp at this stage - HDPE has a high thermal expansion.

You’ll

need to re-tighten these with cool water running through the collectors at a later stage

.

Make sure all nuts are accessible for future tightening.