2

D113727#1

100

65

Ø 3

Ø 3,3

Ø 15

Ø 8

M4

Ø 15

Ø 3

20

32

20

3

12

10

40 50

3

12

20

62

Ø 3,3

Ø 3

M4

Ø 15

Ø 3

20

32

20

3

12

10

40 50

3

12

20

62

Ø 3,3

Ø 3

M4

Ø 15

Ø 3

20

32

20

3

12

10

40 50

3

12

20

62

Ø 3,3

Ø 3

M4

Ø 15

Ø 3

20

32

20

3

12

10

40

50

3

12

20

62

Ø 3,3

Ø 3

M4

Ø 15

Ø 3

20

32

20

3

12

10

40 50

3

12

20

62

Ø 3,3

Ø 3

M4

Ø3,3

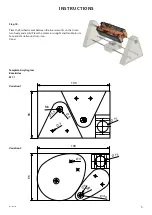

Instructions

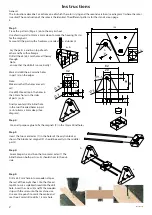

Step 1:

Trace the pattern (Page 5) on to the acrylic sheet.

Use a forstner drill ø 15mm x 3mm deep to make the housing( Part c)

for the magnetsl

Saw out all the parts with a hacksaw, use salad oil as a lubricant

a

b

c

Lay the parts a and b on top of each

other and fix with sellotape

Drill all the ø3/ø3,3 mm holes.all theway

through

Note:

: ensure that the drill bit runs vertically!

Step 2:

Use an all purpose glue to fix the magnets (9) in the 15mm blind holes

Mark and drill the ø 3mm dia holes

in part (c) on the edges

Note:

Make sure that the holes are verti-

cal!

Insert the two metal axles (7) in the holes of the acrylic block as

shown The block and magnet (9) should be exactly in the middle (

part 2)

Step 3:

Assemble parts a and b on the two metal axles (7) The

blind holes on both parts (a+b) should show to the out-

side

Step 4:

b

a

Step 5:

Drill a ø3.3 mm hole into a wooden strip or

the rest of the acrylic sheet. Use the thread

tap M4 to cut a suitable thread into the drill

hole. Insert the screw (4) and fit the wooden

strip with the screw into the machine vice.

Use a centre punch to mark the centre and

use the ø2 mm drill to drill a 1-2 mm hole.

Use a M4 thread tap in the holes in

the 3.3mm holes in the sides

of parts ( a+b)

Finally counter drill a blind hole

in the two threaded holes in part

( a+b) ø 8mm x 3mm deep ( See

diagram ).

a+b

General:

The instructions describe 2 variations one of which the rotor is lying and the second varaition ( see diagram 1)where the rotor

is vertical.The construction of the rotor is the identical. The different patterns for the stands are on page

5.