ONLINE ELECTRONICS LTD

ID5000A_5001_A03

Page 16 of 21

4.2.

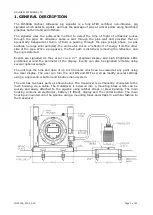

TRANSDUCER INSTALLATION

1.

For optimum results ensure that the pipeline surface at the point of installation is uniform,

clean and smooth. If the surface is irregular, corroded, or has flaking paint then abrasive

paper or a wire brush should be used to prepare the surface. The unit will operate

effectively through most painted layers as long as they are clean, uniform and are fully

bonded to the pipeline surface. The unit will not operate through layers which are not

bonded well to the pipeline surface, coatings which contain air gaps, foam coatings,

concrete coatings, insulated coatings, or composite coatings consisting of several different

materials with different densities. In these cases remove an area of the coating and install

the transducer directly onto the bare pipeline surface.

2.

Before the transducer mounting block is strapped to the pipeline screw it onto the

transducer until the transducer is barely touching the pipeline surface when the transducer

assembly is pressed onto the pipeline. This should mean that when strapped to the

pipeline it should take less than one turn to securely press the transducer face onto the

pipeline surface.

3.

Apply couplant to the centre of the transducer face and to the area of pipeline surface

where the transducer is to be installed.

4.

Securely strap the transducer assembly onto the pipeline surface so the transducer is

transmitting horizontal. If it is mounted vertically and there is a significant amount of gas

in the pipeline fluid then this will tend to float up to the top of the pipe and disturb the

signal path through the pipeline.

5.

Make sure the transducer mounting block is sitting securely on the pipeline so that the

transducer is held perpendicular to the pipeline surface. If the transducer is engaged too

far into its mounting block then you may need to loosen it slightly to allow the mounting

block to sit properly on the pipe surface.

6.

When happy with the transducer mounting block installation hand tighten the transducer

itself onto the pipeline surface. Do not tighten excessively, just enough so that it is secure,

otherwise the transducer face may be damaged. If more than 1 full turn is required to

tighten the transducer then repeat the above procedure from step 2.

7.

Tighten the transducer locking screw to prevent the transducer from turning. Do not

tighten excessively as the mounting block may be damaged.