V1.1-ENG

5

www.onlab.com.tr

gets out from “Programming Mode”. Otherwise, if ESC button is pressed, device returns into

previous menu.

Pressing ENTER button in main menu, displayed program can be started.

If the program has a parameter value, an arrow is displayed at the beginning of lower LCD line.

Parameter value can be changed via DOWN and UP buttons. When ENTER button is pressed,

displayed value is stored. Otherwise, if ESC button is pressed previously stored value is stored

again.

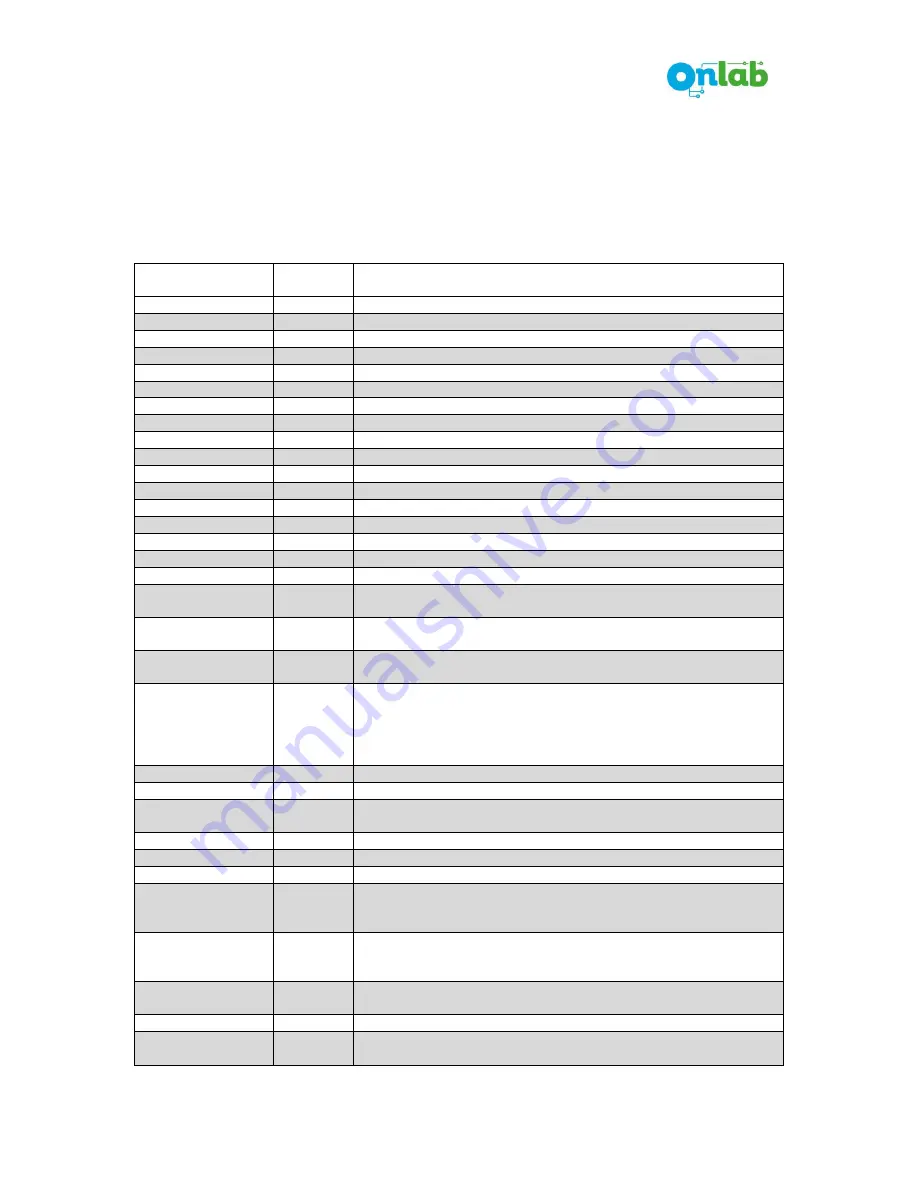

Program

Factory

Settings

Parameters / Explanations

00: Language

Turkce

Turkce – English

01: Open HighSpeed

35 cm/s

20-80 (High speed level while opening)

02: Open LowSpeed

5 cm/s

2-19 (Low speed level while opening)

03: Op. Acc. Dist.

20 cm

5-90 (Total distance of acceleration region while opening)

04: Op. Acc. Jerk

5 cm

1-40 (Distance of acceleration jerk region while opening)

05: Op. Dec. Dist.

15 cm

5-90 (Total distance of deceleration region while opening)

06: Op. Dec. Jerk

5 cm

1-40 (Distance of deceleration jerk region while opening)

07: Op.LowSpdDist

2 cm

1-90 (Distance of low speed region while opening)

08: Op.Pres.Level

% 60

20-100 (Pressure level while opening. % of motor nominal current)

09: Cl.High Speed

25 cm/s

20-80 (High speed level while closing)

10: Cl.Low Speed

5 cm/s

2-19 (Low speed level while closing)

11: Cl.Acc.Dist.

20 cm

5-90 (Total distance of acceleration region while closing)

12: Cl.Acc.Jerk

5 cm

1-40 (Distance of acceleration jerk region while closing)

13: Cl.Dec.Dist.

15 cm

5-90 (Total distance of deceleration region while closing)

14: Cl.Dec.Jerk

5 cm

1-40 (Distance of deceleration jerk region while closing)

15: Cl.LowSpdDist

5 cm

1-90 (Distance of low speed region while closing)

16: Cl.Pres.Level

% 45

20-100 (Pressure level during closing. % of motor nominal current)

17: Run InputType

Open -

Close

Open - Close, Close

(Selection of door operation with inputs.)

18: Limit Relays

Open

Contact

Open Contact, Close Contact

(Selection of limit relay operation when reached to limit)

19: Fault Relay

Open

Contact

Open Contact, Close Contact

(Fault relay operation if an error or photocell signal is detected)

20: Demo Mode

0 s

0 – 30

(Time for demo operation. 0 means demo is cancelled. Any value other

than 0 runs the door in demo mode in which door opens and closes

consecutively whatever the input signals are. At opened limit and closed

limit door waits for selected time.)

21: SetUserPassw.

(User password can be set.)

22: CancelU.Pass?

(User password is changed with 0000 and cancelled)

23: Cl.LowSpdPres

% 45

20-100

(Pressure level at closing low speed region. % of motor nominal current)

24: EIN1 Input

Nudging

Nudging / Photocell

25: EIN2 Input

Photocell

Nudging / Photocell

26: Door Type

Telescopic

Telescopic-Central-Internal

27: Motor Type

Motor 1-Motor 2- Motor 3 (This parameter cannot be modified,

preprogrammed by Onlab according to the motor type the driver is

matched at the production)

28: Working Mode

NORMAL

NORMAL / SOFT CLOSE

(If this parameter is selected as SOFT CLOSE, door press level does not

exceed 150 N during closing operation)

29: Encoder Match

Passive

Active-Passive (After the serial production in Onlab, encoder matching

process is done. Drivers are sent to the customer after this operation.)

Manufact. Set.

CAUTION! Only the door manufacturer can reach those parameters.

99: Factory Set ?

(If this parameter is set, all of the parameter values will be reset to

factory settings.)

*Factory Setting values can be different in customer specific software.