OIL-HYDRAULIC PRESSES WITH TWO UPRIGHTS

OPERATION AND MAINTENANCE MANUAL

10

3.3

MACHINE USE

The "OPI" oil-hydraulic presses with two uprights are usually double-effect machines with slide and cushion

control; they are used to blank, coin and draw steel plates into shapes and sizes which should be in line with

the technical specifications of the relevant model.

For further information regarding the above, refer to the machine test certificate at the beginning of this operation

and maintenance manual.

DANGER:

The press is not intended for machining materials which can entail risks of parts being flung

about.

There is only one planned working position for the manual loading and unloading of the piece and this is located

at the front of the machine where the control console complete with safety distance ring is situated.

The machine has been designed to be operated by only one operator.

DANGER:

It is forbidden to operate the machine if other people are in or around the machine danger zone.

The control console should be positioned so that the operator can control the slide and the blank-holder

cushion in safe conditions.

To prevent the operator from entering the machine danger zone from the front, a spacer ring is attached to the

control console; the dimensions of this ring depend on the stopping time of the slide measured during the rapid

downstroke movement.

DANGER:

It is forbidden to remove the spacer of the control console.

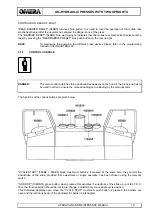

To prevent the access of the operator from the back, these machines have a (standard) pneumatically

controlled mobile guard in the lower part, governed by electrical limiting devices. In the upper part there is a

fixed guard which can be controlled (as an optional) by a safety liming device.

The 53SA21 selector is used to deactivate the mechanical movable barrier located on the back of the machine

during any operation mode (adjustment, single and automatic). In this case, protection to the operator on the

rear side is provided (by the user) by a set of fixed barriers with access gates (with opening controlled by safety

limit switches).

The guards installed by the user must be constructed and checked according with the following standards in

force:

EN292-2

Safety of machinery - Fundamental concepts, main design principles. Part 2: technical principles

and specifications.

EN294

Safety of machinery - Safety distances to prevent danger zones being reached by upper limbs.

EN953

Safety of machinery - General requirements for designing and constructing (fixed, mobile)

projectors

EN1088

Safety of machinery - Safety of machinery - Blocking and interlocking devices - General principles

and design requirements.

To prevent the operator from entering the machine danger zone from the side, the oil-hydraulic presses with two

uprights are fitted with fixed mechanical barriers controlled by limit switches. Closing position is controlled by

two safety limit switches.

DANGER:

It is forbidden to remove the fixed guards or tamper with the mechanical barrier limit switches.

The oil-hydraulic presses with two uprights are provided with an automatic slide hooking device which locks the

slide downstroke due to its own weight when the machine is unattended.

To use this device, refer to chapter “USE CONDITIONS”.

DANGER:

Any operations except for piece loading / unloading carried out inside the danger zone of

the press depends on the correct use of the slide locking device and the main pump stop.

Содержание OPI M-400

Страница 4: ...OIL HYDRAULIC PRESSES WITH TWO UPRIGHTS OPERATION AND MAINTENANCE MANUAL 4 1 MACHINE ASSEMBLY DRAWING...

Страница 42: ...OIL HYDRAULIC PRESSES WITH TWO UPRIGHTS OPERATION AND MAINTENANCE MANUAL 42 7 14 COMPARATIVE OIL TABLES...

Страница 43: ...OIL HYDRAULIC PRESSES WITH TWO UPRIGHTS OPERATION AND MAINTENANCE MANUAL 43 7 15 WIRING DIAGRAM...

Страница 44: ...OIL HYDRAULIC PRESSES WITH TWO UPRIGHTS OPERATION AND MAINTENANCE MANUAL 44 7 16 OIL HYDRAULIC DIAGRAM...

Страница 45: ...OIL HYDRAULIC PRESSES WITH TWO UPRIGHTS OPERATION AND MAINTENANCE MANUAL 45 7 17 PNEUMATIC DIAGRAM...

Страница 46: ...OIL HYDRAULIC PRESSES WITH TWO UPRIGHTS OPERATION AND MAINTENANCE MANUAL 46 7 18 LUBRICATION SYSTEM DIAGRAM...

Страница 47: ...OIL HYDRAULIC PRESSES WITH TWO UPRIGHTS OPERATION AND MAINTENANCE MANUAL 47 7 19 TABLE DRAWING...

Страница 48: ...OIL HYDRAULIC PRESSES WITH TWO UPRIGHTS OPERATION AND MAINTENANCE MANUAL 48 7 20 SLIDE DRAWING...

Страница 49: ...OIL HYDRAULIC PRESSES WITH TWO UPRIGHTS OPERATION AND MAINTENANCE MANUAL 49 7 21 KNOCKOUT DRAWING...

Страница 50: ...OIL HYDRAULIC PRESSES WITH TWO UPRIGHTS OPERATION AND MAINTENANCE MANUAL 50 7 22 OTHER DRAWINGS...