10-1

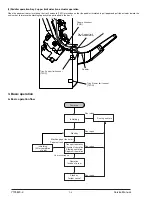

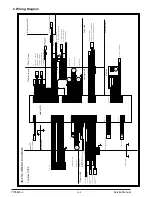

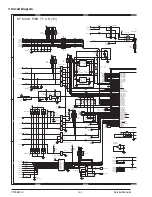

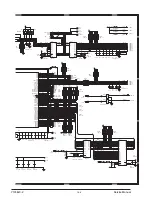

[10] BLOCK DIAGRAM, WIRING DIAGRAM

1. Block Diagram

Staple Unit Motor

AR-FN6

Elevator Motor

Paper Push Solenoid

Staple Compiler Gate Solenoid

Finisher Gate Solenoid

Tray2 Solenoid

Stopper Solenoid

Staple unit Turn Motor

Pushher Motor

4

Jogger Front Motor

Jogger Rear Motor

Pushher Home Position sensor

Staple Compiler Paper Detect sensor

Jogger Front Home Position sensor

Tray1 Paper Full detect sensor

Staple Turn Home Position sensor2

Paper In Detect sensor

Paper Out Detect sensor

Tray2 Down detect sensor

Staple Compiler In Detect sensor2

Staple Compiler In Detect sensor

Staple Turn Home Position sensor1

Tray2 Upper detect sensor

Jogger Rear Home Position sensor

Tray2 Output Motor

Main Motor

Stapler No Cartridge sensor

Stapler Home Position sensor

Stapler Self Priming sensor

Stapler Low Staple sensor

Stapler Motor

Stapler

Tray2 Paper Detect sensor

Door SWitch 1

AR-DC1

Staple Compiler Rolor Solenoid

Paper Push Detect sensor

Door Open Detect sensor

(74HC151)

(74HC151)

(MTD1361F)

(MTD1361F)

(MTD1361F)

(MTD1361F)

4

JFM

+24V

4

4

JRM

+24V

4

4

(MTD1361)

4

+24V

PSM

4

4

STUM

+24V

+24V

T2OM

4

MM

+24V1

2

2

CPU

(uPD784214AGC)

(STA457C)

2

EVM

2

STTM

2

2

(2SB1198K x4)

+24V

SCGS

PPS

+24V

+24V

SPS

T2S

+24V

SCRS

+24V

FGS

+24V

(TD62003AP)

GND1

GND2

FG

3

3

2

A ~ C

A ~ C

P70 ~ P72

Y

Y

SEL0 ~ SEL2

T1PF

+5V

(1-B3)

(1-D3)

DSW1

DSW2

Door SWitch 2

SCPD

+5V

+5V

PPD

JRHP

+5V

+5V

JFHP

T2PD

+5V

+5V

T2UP

T2DN

+5V

+5V

POD

SCID2

+5V

+5V

PID

SCID

+5V

PSHP

+5V

+5V

STTHP2

+5V

+5V

DOPD

(1-D3)

STTHP1

A8 ~ A16

AD0 ~ AD7

LATCH

EPROM 1M

(74HC373)

LE

A8 ~ A16

A0 ~ A7

D0 ~ D7

(M27C1001)

OE

A8 ~ A16

AD0 ~ AD7

A0 ~ A7

STM

STHP

STNC

STLS

STUHP

Staple Unit Home Position sensor

(1-B3)

STSP

+5V

(2SB1198K x4)

+5V

AR-FN6 BLOCK DIAGRAM

P80 ~ 83

P84 ~ 87

P131

RTP4 ~ RTP7

P00

P30 ~ 33

P132

P130

RTP0 ~ RTP7

P102

P103

P100,101

P92,93

P90,91

P24

P25

P26

P27

P94

/RESET

P22

P23

TXD1

RXD1

P16

D7

D1

D2

P17

D6

D5

D4

D2

INTP2

INTP4

INTP5

P12

P11

P15

P14

P13

P36

P10

P35

P34

D1

D3

P01

RD

ASTB

P37

INTP3

D0

JPD

PSPD

STUPD

T2OPD

MME

MMCK

FGS-FIN2/

RES-FIN2

DTR-FIN2/

DSR-FIN2/

TXD-FIN2

RXD-FIN2

IN0

DSW1

DSW2

24VM

IN1

RD

ASTB

+5V

+24V

+24V

+24V1

+24V2

+24V2

+24V2

STNC

STSP

STSP

STLS

MMLK

STLS

STNC

MMLK

A

A

B

B

C

C

D

D

E

E

4

4

3

3

2

2

1

1

T

ransistor

arr

a

y

(Option po

w

er)

Main PWB

Input b

uff

er

Input b

uff

er

Input b

uff

er

Multiple

x

er 1

Multiple

x

er 2

+24V

monitor

(le

vel

con

ver

ter)

circuit

Input b

uff

er

Input b

uff

er

Input b

uff

er

Input b

uff

er

Output b

uff

er

Output b

uff

er

Input b

uff

er

Chopping

circuit

Chopping

circuit

Chopping

circuit

Chopping

circuit

Chopping

circuit

Output b

uff

er

Output b

uff

er

H br

idge

circuit

H br

idge

circuit

H br

idge

circuit

"# $%&'()

Y105

620

-

2

Service Manual