13

Anti-Kickback Fingers

Anti-kickback fingers help prevent stock from

being kicked out of the machine towards the

user. Keep the fingers clean and free from

sawdust, pitch gum, etc., so they operate

smoothly.

Adjustment of In-Feed Roller

The in-feed roller should be set 0.02” below the

lowest point of knife. Make sure the knives are

set properly see the “Setting / Changing Knives”

section on page 11 prior to making any

adjustments.

1.

Disconnect machine from power source.

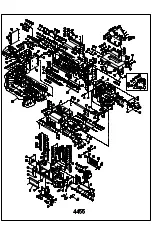

2. Place a hard wood gauge (A, Figure 13)

under a knife in cutterhead. Place a 0.02”

feeler gauge (B, Figure 13) on top of wood

block and raise table until feeler gauge

contacts the knife in its lowest position.

3. Remove feeler gauge and place wood block

under the left side of in-feed roller. The top

of wood gauge should just contact the in-

feed roller. If it doesn’t, loosen jam nut (C,

Figure 14) and turn the adjusting screw (D,

Figure 14) to raise, or lower the in-feed roller

until it contacts wood gauge. Repeat for

opposite side of the in-feed roller.

Adjustment of Chipbreaker

Chipbreaker should be set 0.02” below the

lowest point of knife. Make sure the knives are

set properly see the “Setting / Changing Knives”

section on page 11 prior to making any

adjustments.

1.

Disconnect machine from power source.

2. Place a hard wood gauge (A, Figure 13)

under a knife in the cutterhead. Place a

0.02” feeler gauge (B, Figure 13) on top of

wood block and raise table until the gauge

contacts the knife in its lowest position.

3. Remove feeler gauge and place wood

gauge (E, Figure 15) under the left side of

chipbreaker (F, Figure 15). The top of the

wood gauge should just contact the

chipbreaker. If it doesn’t, remove the socket

head cap screw (G, Figure 14) and insert a

shim (H, Figure 14) of proper thickness in-

between castings until chipbreaker contacts

the wood gauge. Repeat for opposite side

of the chipbreaker.

Содержание 4455

Страница 19: ......